The Science Behind PUF Sandwich Panels' Thermal Efficiency

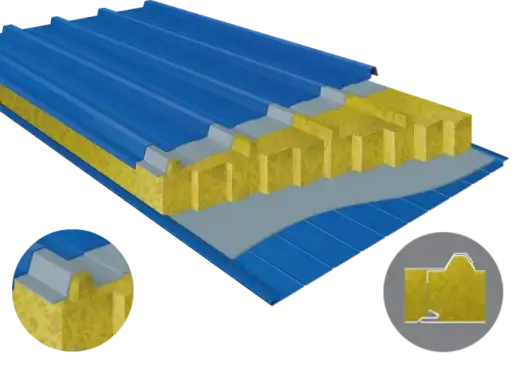

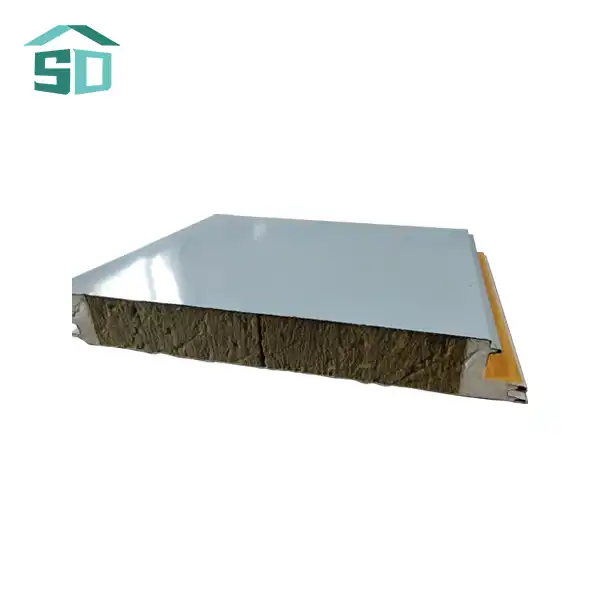

Understanding the thermal efficiency of PUF sandwich panels requires delving into the science of heat transfer. These panels excel in minimizing all three modes of heat transfer: conduction, convection, and radiation.

Conduction Resistance

The polyurethane foam core in PUF sandwich panels is a poor conductor of heat. Its low thermal conductivity, typically ranging from 0.022 to 0.028 W/mK, significantly impedes heat flow through the material. This property is due to the foam's cellular structure, which consists of millions of tiny closed cells filled with low-conductivity gases. As heat attempts to move through the panel, it encounters numerous barriers, effectively slowing its progress.

Convection Prevention

The closed-cell structure of the PUF core also plays a crucial role in preventing convective heat transfer. By trapping air within its cells, the foam eliminates the possibility of air circulation, which is a primary mechanism for convective heat transfer. This stagnant air acts as an additional insulating layer, further enhancing the panel's thermal performance.

Radiation Reflection

The metal facings of PUF sandwich panels contribute to their thermal efficiency by reflecting radiant heat. Aluminum facings, in particular, have a high reflectivity, bouncing back a significant portion of incident radiant energy. This reflective property is especially beneficial in hot climates, where it helps to reduce the heat gain from solar radiation.

Quantifying the Thermal Performance of PUF Sandwich Panels

To fully appreciate the thermal efficiency of PUF sandwich panels, it's essential to examine the quantitative measures used to assess their performance.

R-Value and U-Value

The thermal resistance of PUF sandwich panels is often expressed in terms of R-value or U-value. R-value measures the panel's resistance to heat flow, with higher values indicating better insulation. PUF sandwich panels typically have R-values ranging from R-5 to R-8 per inch of thickness, depending on the foam density and composition. U-value, the inverse of R-value, represents the rate of heat transfer through the panel. Lower U-values indicate superior insulating properties. PUF sandwich panels can achieve U-values as low as 0.15 W/m²K, making them highly effective in minimizing heat transfer.

Thermal Bridging Reduction

PUF sandwich panels excel in reducing thermal bridging, a common issue in traditional construction methods. Thermal bridges are areas where heat can easily transfer through the building envelope, often occurring at joints or connections. The continuous insulation provided by PUF panels minimizes these weak points, resulting in a more uniform thermal barrier. This reduction in thermal bridging can lead to energy savings of up to 20% compared to conventional insulation methods.

Temperature Differential Maintenance

The effectiveness of PUF sandwich panels in maintaining temperature differentials is remarkable. In controlled tests, buildings constructed with these panels have demonstrated the ability to maintain internal temperatures within ±2°C of the desired set point, even when external temperatures fluctuate by as much as 30°C. This stability is crucial for applications such as cold storage facilities, where consistent temperatures are essential for product integrity.

Practical Applications and Benefits of PUF Sandwich Panels

The superior thermal properties of PUF sandwich panels make them invaluable in various construction and industrial applications.

Energy-Efficient Building Envelopes

In commercial and residential construction, PUF sandwich panels serve as an integral component of energy-efficient building envelopes. Their high insulation value contributes to significant reductions in heating and cooling costs. Studies have shown that buildings utilizing PUF sandwich panels can achieve energy savings of up to 30% compared to traditional construction methods. This efficiency not only reduces operational costs but also contributes to lower carbon emissions, aligning with global sustainability goals.

Cold Storage and Refrigeration

The food and pharmaceutical industries rely heavily on PUF sandwich panels for cold storage and refrigeration applications. These panels maintain precise temperature control, crucial for preserving perishable goods and sensitive materials. The panels' ability to resist moisture penetration also prevents condensation issues, which can be detrimental in cold storage environments. In large-scale refrigerated warehouses, PUF sandwich panels have been shown to reduce energy consumption by up to 40% compared to conventional insulation systems.

Industrial Process Temperature Control

Many industrial processes require strict temperature control for optimal efficiency and product quality. PUF sandwich panels are employed in manufacturing facilities to create controlled environments for sensitive operations. For instance, in the electronics industry, clean rooms insulated with PUF panels maintain stable temperatures within ±0.5°C, ensuring consistent production conditions for delicate components.

Conclusion

PUF sandwich panels have revolutionized thermal insulation in construction and industrial applications. Their unique composition of a polyurethane foam core sandwiched between metal facings creates an exceptional barrier against heat transfer. By effectively minimizing conduction, convection, and radiation, these panels achieve remarkable thermal efficiency. The quantifiable benefits, including high R-values, reduced thermal bridging, and precise temperature control, make PUF sandwich panels an indispensable solution for energy-efficient buildings and temperature-sensitive environments.

At Weifang Sandong Building Materials Co., Ltd., we're committed to providing top-quality PUF sandwich panels that meet the highest standards of thermal efficiency and durability. Our panels are customizable to suit your specific project needs, offering a range of thicknesses, colors, and finishes. Whether you're working on a residential, commercial, or industrial project, our PUF sandwich panels can help you achieve your energy efficiency goals. For more information on how our products can benefit your next project, don't hesitate to contact us at info@sdqsc.com.

FAQs

What is the typical lifespan of PUF sandwich panels?

PUF sandwich panels can last 30-50 years with proper maintenance.

Are PUF sandwich panels environmentally friendly?

Yes, they contribute to energy efficiency and are often made with recyclable materials.

Can PUF sandwich panels be used in fire-prone areas?

Many PUF panels are available with fire-resistant ratings, such as Class B1.

How do PUF sandwich panels compare to traditional insulation methods?

They often outperform traditional methods in terms of insulation value and ease of installation.

Are PUF sandwich panels suitable for both new construction and retrofitting?

Yes, they are versatile and can be used in both new builds and renovation projects.

References

1. Berardi, U., & Naldi, M. (2017). The impact of the temperature dependent thermal conductivity of insulating materials on the effective building envelope performance. Energy and Buildings, 144, 262-275.

2. Cabeza, L. F., Castell, A., Medrano, M., Martorell, I., Pérez, G., & Fernández, I. (2010). Experimental study on the performance of insulation materials in Mediterranean construction. Energy and Buildings, 42(5), 630-636.

3. Lorenzati, A., Fantucci, S., Capozzoli, A., & Perino, M. (2016). The effect of different materials joint on the thermal performance of reflective insulation systems. Energy Procedia, 78, 261-266.

4. Papadopoulos, A. M. (2005). State of the art in thermal insulation materials and aims for future developments. Energy and Buildings, 37(1), 77-86.

5. Schiavoni, S., D׳Alessandro, F., Bianchi, F., & Asdrubali, F. (2016). Insulation materials for the building sector: A review and comparative analysis. Renewable and Sustainable Energy Reviews, 62, 988-1011.