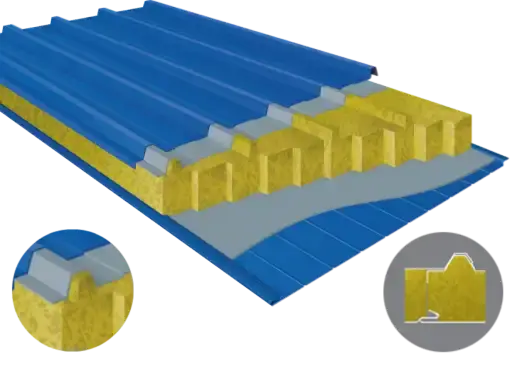

The Relationship Between Panel Thickness and Insulation Properties

The thickness of insulation boards and sandwich panels directly correlates with their thermal performance. As we delve into the specifics of the 10 cm sandwich panel, it's essential to understand how thickness affects key insulation properties:

Thermal Resistance (R-Value)

The R-value, which quantifies a material’s thermal resistance, increases proportionally with the panel’s thickness. A 10 cm sandwich panel offers significantly better insulation performance compared to thinner panels, effectively minimizing heat transfer through walls or roofs. This enhanced thermal barrier contributes to greater energy efficiency in buildings, maintaining comfortable indoor temperatures year-round. Over time, this results in substantial savings on heating and cooling expenses, making 10 cm sandwich panels a smart choice for energy-conscious construction projects.

Sound Insulation

Thicker panels, such as the 10 cm sandwich panel, generally provide enhanced sound insulation. Their additional mass and dense core structure allow them to better absorb and reduce noise transmission between rooms or from external sources. This makes them ideal for residential, industrial, and commercial environments where quiet and comfort are essential. Whether used in apartment buildings, offices, or manufacturing facilities, these panels significantly enhance overall sound control and occupant satisfaction.

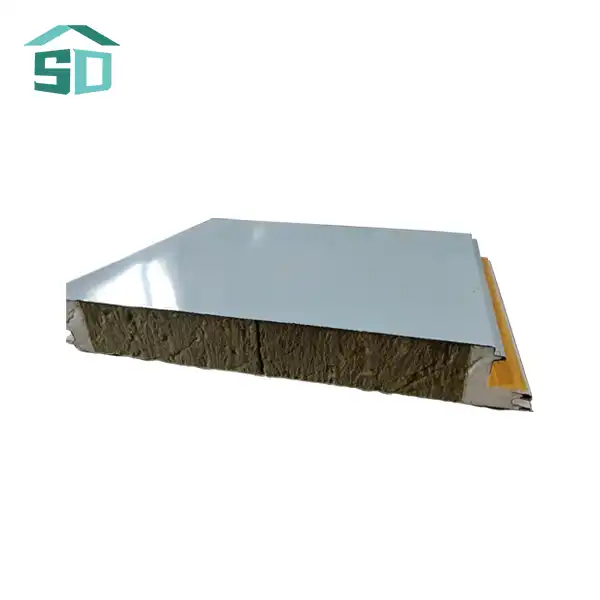

Moisture Resistance

Although thickness alone does not determine moisture resistance, a 10 cm sandwich panel often features enhanced protective layers and improved sealing systems. These reinforcements create a more effective barrier against water ingress and condensation. As a result, the panels offer better protection against corrosion, mold, and structural damage caused by long-term exposure to humidity. In high-moisture or coastal regions, this added durability ensures longer service life and reduced maintenance requirements, further boosting the panel’s long-term value.

Impact of Panel Thickness on Structural Performance

Beyond insulation properties, the thickness of sandwich panels significantly influences their structural capabilities. Let's examine how the 10 cm sandwich panel and similar thick options affect various structural aspects:

Load-Bearing Capacity

Thicker panels, including the 10 cm sandwich panel, generally offer increased load-bearing capacity. This allows for greater spans between supports, potentially reducing the need for additional structural elements in a building's design. For large-scale industrial or commercial projects, this can lead to substantial cost savings in overall construction.

Wind Resistance

Panel thickness plays a crucial role in a building's ability to withstand wind loads. The 10 cm sandwich panel, with its robust profile, provides enhanced resistance to wind pressure compared to thinner alternatives. This is particularly important for tall structures or buildings in areas prone to high winds or storms.

Fire Resistance

Thicker panels often offer improved fire resistance due to the increased mass and potential for incorporating fire-retardant materials. While specific fire ratings depend on the panel's core material and construction, a 10 cm sandwich panel typically provides better fire protection than thinner options, contributing to overall building safety.

Economic Considerations: Balancing Thickness, Price, and Performance

While thicker panels like the 10 cm sandwich panel offer numerous performance benefits, it's essential to consider the economic implications of panel thickness:

Initial Cost vs. Long-Term Savings

Thicker panels, such as the 10 cm sandwich panel, generally come with a higher upfront cost. However, the improved insulation properties can lead to significant energy savings over the building's lifetime. When evaluating panel options, it's crucial to consider both initial expenses and potential long-term benefits.

Installation Considerations

The thickness of panels can impact installation time and complexity. While a 10 cm sandwich panel may require specialized handling equipment due to its weight, the reduced number of panels needed for a given area can potentially offset these challenges. Engaging with experienced 10 cm sandwich panel suppliers can help optimize the installation process.

Lifecycle Cost Analysis

When assessing the true economic impact of panel thickness, it's essential to conduct a comprehensive lifecycle cost analysis. This should include factors such as energy savings, maintenance requirements, and potential replacement costs. In many cases, the superior durability and performance of thicker panels like the 10 cm sandwich panel can justify the higher initial investment.

Conclusion

The thickness of insulation boards and sandwich panels plays a pivotal role in determining both their price and performance. While thicker options like the 10 cm sandwich panel may come with a higher upfront cost, they often deliver superior thermal insulation, enhanced structural capabilities, and improved long-term value. By carefully considering the specific requirements of your project and consulting with reputable suppliers, you can strike the optimal balance between panel thickness, performance, and budget.

At Weifang Sandong Building Materials Co., Ltd., we understand the importance of selecting the right panel thickness for your construction needs. Our range of high-quality insulation boards and sandwich panels, including the versatile 10 cm sandwich panel, are designed to meet the diverse requirements of modern building projects. Whether you're prioritizing energy efficiency, structural integrity, or aesthetic appeal, our expert team is here to help you make an informed decision. To learn more about our products or to discuss your specific project requirements, don't hesitate to reach out to us at info@sdqsc.com.

FAQ

How does the thickness of a sandwich panel affect its insulation properties?

Thicker panels, like the 10 cm sandwich panel, generally provide better thermal insulation due to increased R-value. They also offer improved sound insulation and can incorporate more robust moisture barriers.

Are thicker sandwich panels always better for all construction projects?

While thicker panels often offer superior performance, the ideal thickness depends on specific project requirements, budget constraints, and local building codes. It's essential to consult with experts and consider factors such as climate, building use, and long-term energy costs.

How does panel thickness impact installation costs?

Thicker panels may require specialized equipment for handling, potentially increasing installation costs. However, fewer panels are needed to cover the same area, which can offset some of these expenses. Consulting with experienced 10 cm sandwich panel suppliers can help optimize the installation process and overall project costs.

References

1. American Society of Heating, Refrigerating and Air-Conditioning Engineers. (2017). ASHRAE Handbook: Fundamentals. ASHRAE.

2. Berardi, U., & Naldi, M. (2017). The impact of the temperature dependent thermal conductivity of insulating materials on the effective building envelope performance. Energy and Buildings, 144, 262-275.

3. International Code Council. (2018). International Building Code. ICC.

4. Papadopoulos, A. M. (2005). State of the art in thermal insulation materials and aims for future developments. Energy and Buildings, 37(1), 77-86.

5. U.S. Department of Energy. (2020). Energy Saver: Insulation.