The Economics of Prefabricated Thermal Panels

Initial Investment and Long-Term Savings

Prefabricated thermal panels represent a significant leap forward in construction technology, offering a blend of efficiency and cost-effectiveness. While the initial investment in these panels may be higher than traditional wall systems, the long-term benefits often outweigh the upfront costs. Prefabricated thermal panels boast superior insulation properties, which translate into substantial energy savings over the lifetime of a building. This reduction in energy consumption not only lowers utility bills but also contributes to a smaller carbon footprint, aligning with modern sustainability goals.

The economic advantages of prefabricated thermal panels extend beyond mere energy savings. These panels are engineered for rapid installation, dramatically reducing on-site construction time. This efficiency translates into lower labor costs and earlier project completion, allowing for quicker occupancy and return on investment. Moreover, the precision manufacturing of prefabricated thermal panels minimizes material waste, further contributing to cost savings and environmental stewardship.

Maintenance and Durability Considerations

When evaluating the long-term economics of prefabricated thermal panels, it's crucial to consider their durability and maintenance requirements. These panels are designed to withstand harsh environmental conditions, offering superior resistance to moisture, UV radiation, and temperature fluctuations. This resilience results in reduced maintenance needs and a longer lifespan compared to traditional wall systems.

The robust construction of prefabricated thermal panels also contributes to their longevity. Manufactured under controlled conditions, these panels maintain consistent quality, reducing the likelihood of defects that can lead to costly repairs. Additionally, their modular nature allows for easy replacement of individual panels if damage does occur, minimizing repair costs and downtime. This durability and ease of maintenance contribute significantly to the overall cost-effectiveness of prefabricated thermal panels over the life of a building.

Performance Metrics: Thermal Efficiency and Structural Integrity

Insulation Capabilities and Energy Performance

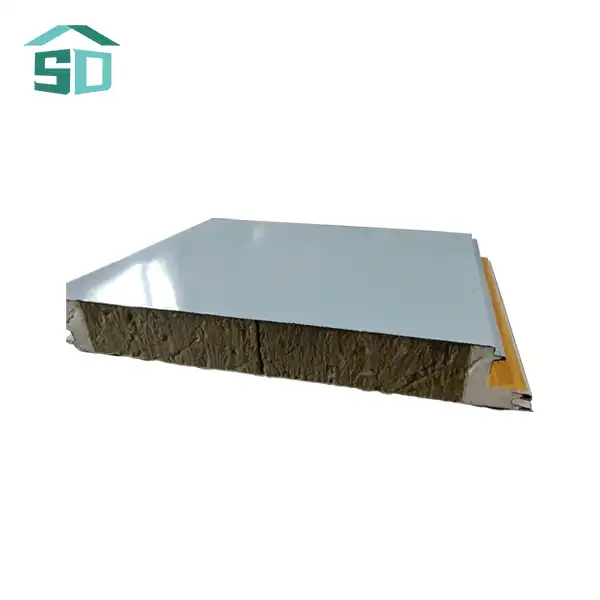

Prefabricated thermal panels excel in providing superior insulation, a critical factor in modern construction. These panels are engineered with high-performance insulating materials, such as polyurethane or polystyrene, which offer exceptional thermal resistance. The insulation core is sandwiched between durable exterior and interior facings, creating a thermal barrier that significantly reduces heat transfer. This design allows prefabricated thermal panels to achieve R-values far exceeding those of traditional wall assemblies, resulting in more stable indoor temperatures and reduced heating and cooling loads.

The energy performance of prefabricated thermal panels is further enhanced by their airtight construction. The precision-engineered joints between panels minimize air leakage, a common issue in traditional wall systems. This airtightness not only improves thermal efficiency but also contributes to better indoor air quality by reducing the infiltration of outdoor pollutants. As energy codes become increasingly stringent, the superior insulation capabilities of prefabricated thermal panels position them as a future-proof solution for energy-efficient building envelopes.

Structural Strength and Load-Bearing Capacity

Beyond their thermal properties, prefabricated thermal panels offer impressive structural performance. These panels are designed to provide both insulation and structural support, often eliminating the need for additional framing. The composite nature of prefabricated thermal panels, with their rigid insulation core bonded to strong exterior and interior facings, creates a lightweight yet robust structural element. This design allows the panels to efficiently distribute loads and resist both lateral and vertical forces.

The structural integrity of prefabricated thermal panels is rigorously tested to meet or exceed building code requirements. Their load-bearing capacity can be tailored to specific project needs, making them suitable for a wide range of applications, from low-rise residential buildings to large-scale commercial structures. This versatility, combined with their inherent strength, makes prefabricated thermal panels an attractive option for architects and engineers seeking to optimize building performance while simplifying the construction process.

Installation Process and Time Efficiency

Streamlined Construction Techniques

The installation of prefabricated thermal panels represents a paradigm shift in construction methodology, offering unparalleled efficiency and precision. These panels are designed for rapid assembly, with interlocking systems and pre-engineered connections that simplify the installation process. Unlike traditional wall construction, which involves multiple trades and on-site fabrication, prefabricated thermal panels arrive at the job site ready for immediate installation. This streamlined approach significantly reduces the potential for errors and inconsistencies that can plague conventional building methods.

The efficiency of prefabricated thermal panel installation is further enhanced by the reduced need for specialized equipment. Many panels can be maneuvered and secured with minimal machinery, reducing logistical complexities on the construction site. Moreover, the lightweight nature of these panels, compared to traditional masonry or concrete walls, allows for easier handling and placement. This not only speeds up the construction process but also reduces the physical strain on workers, contributing to improved site safety and productivity.

Labor Requirements and Skill Sets

The adoption of prefabricated thermal panels has significant implications for labor requirements and the skills needed on construction sites. The simplified installation process typically requires fewer workers compared to traditional wall construction, potentially leading to substantial labor cost savings. Additionally, the specialized nature of panel installation can lead to the development of highly skilled installation teams, further improving efficiency and quality as they become more experienced with the system.

While the installation of prefabricated thermal panels may require some initial training, the learning curve is generally less steep than that of traditional construction methods. This accessibility allows for a broader pool of workers to quickly become proficient in panel installation, potentially addressing labor shortages in the construction industry. Furthermore, the reduced on-site construction time minimizes weather-related delays and associated labor costs, contributing to more predictable project timelines and budgets.

Conclusion

Prefabricated thermal panels offer a compelling alternative to traditional wall construction, balancing initial costs with long-term benefits. Their superior insulation properties, structural integrity, and rapid installation process contribute to significant energy savings and reduced construction timelines. While the upfront investment may be higher, the long-term economic and environmental advantages make prefabricated thermal panels an attractive option for modern construction projects. As the industry continues to evolve towards more sustainable and efficient building practices, these innovative panels are poised to play an increasingly important role in shaping the future of construction.

Are you ready to revolutionize your next construction project with cutting-edge prefabricated thermal panels? As a leading prefabricated thermal panels supplier, Weifang Sandong Building Materials Co., Ltd. offers customized solutions to meet your specific needs. Our panels combine superior insulation, durability, and aesthetic appeal, ensuring your project stands out in both performance and design. Contact us today at info@sdqsc.com to discover how our prefabricated thermal panels can enhance your building's efficiency and sustainability.

FAQs

How do prefabricated thermal panels compare to traditional insulation methods in terms of R-value?

Prefabricated thermal panels typically offer higher R-values per inch of thickness compared to traditional insulation methods. Our panels can achieve R-values of up to R-8 per inch, significantly outperforming conventional fiberglass or cellulose insulation.

Are prefabricated thermal panels suitable for both new construction and retrofitting projects?

Yes, our prefabricated thermal panels are versatile and can be used in both new construction and renovation projects. Their modular design allows for easy integration into existing structures, making them an excellent choice for energy-efficient upgrades.

What is the typical lifespan of prefabricated thermal panels?

With proper installation and maintenance, our prefabricated thermal panels can last 30-50 years or more, offering excellent long-term value for your investment.

References

1.U.S. Department of Energy. (2021). "Energy Saver: Insulation"

2.International Energy Agency. (2020). "Energy Efficiency in Buildings"

3.National Institute of Building Sciences. (2019). "Whole Building Design Guide: Building Envelope Design Guide"

4.American Society of Heating, Refrigerating and Air-Conditioning Engineers. (2021). "ASHRAE Handbook: Fundamentals"

5.Straube, J., & Burnett, E. (2005). "Building Science for Building Enclosures"