The Evolution of Eco-Friendly Insulation Technology

The development of green thermal insulation panels represents a significant leap forward in sustainable building practices. Traditional insulation materials often fall short in terms of environmental impact and long-term performance. In contrast, these innovative panels utilize renewable resources and recycled materials, minimizing their carbon footprint while maximizing efficiency.

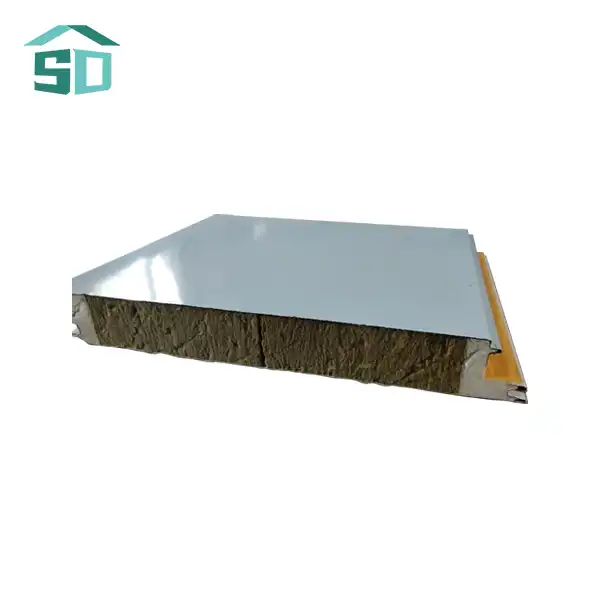

Advanced manufacturing processes have enabled the creation of panels that offer superior thermal resistance without compromising on durability or moisture protection. The incorporation of natural fibers, such as hemp or recycled cotton, alongside high-performance synthetic materials, results in a product that balances eco-consciousness with exceptional functionality.

Pioneering Materials in Green Insulation

Green thermal insulation panels leverage a diverse array of sustainable materials, each contributing unique properties to the final product. Recycled denim, for instance, provides excellent sound absorption while offering thermal insulation comparable to fiberglass. Sheep's wool, another natural option, not only insulates effectively but also possesses inherent moisture-wicking capabilities, enhancing the panel's resistance to dampness.

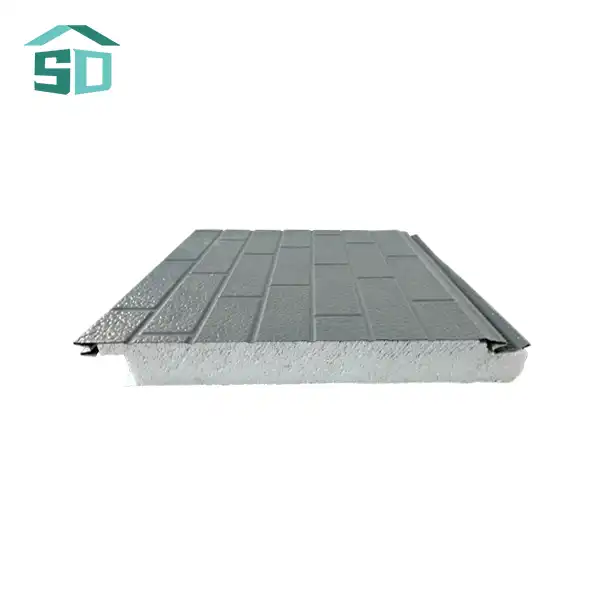

Innovative synthetic options, such as aerogel-infused panels, push the boundaries of insulation technology. Derived from silica gel, aerogel is an ultralight material with remarkable insulating properties, capable of providing significant thermal resistance even in thin layers. This allows for slimmer panel profiles without sacrificing performance, an invaluable feature in space-constrained urban environments.

Technological Advancements in Panel Design

The design of green thermal insulation panels has evolved to incorporate sophisticated moisture management systems. Vapor-permeable layers allow for the controlled passage of water vapor, preventing condensation within the panel structure. This breathability is crucial in maintaining a healthy indoor environment and preserving the structural integrity of the building envelope.

Nanotechnology plays a pivotal role in enhancing the moisture resistance of these panels. Hydrophobic coatings at the nanoscale level repel water molecules, creating a barrier against moisture infiltration while maintaining the panel's thermal properties. This technology ensures that the insulation remains effective even in challenging climatic conditions, from humid coastal areas to regions with heavy rainfall.

Environmental Impact and Sustainability

The adoption of green thermal insulation panels represents a significant stride towards reducing the environmental impact of the construction industry. These panels not only contribute to energy conservation during a building's operational life but also address concerns related to the entire lifecycle of insulation materials.

Manufacturers of green thermal insulation panels prioritize the use of recycled and renewable resources, significantly reducing the demand for virgin materials. This approach not only conserves natural resources but also minimizes waste generation. Many panels are designed with end-of-life considerations in mind, featuring components that can be easily separated and recycled, further reducing their environmental footprint.

Energy Efficiency and Carbon Footprint Reduction

The superior insulating properties of green thermal panels translate directly into reduced energy consumption for heating and cooling. Buildings equipped with these panels require less energy to maintain comfortable indoor temperatures, resulting in lower greenhouse gas emissions associated with HVAC systems. Over the lifespan of a building, this energy savings can amount to a substantial reduction in carbon footprint.

Moreover, the production process of green thermal insulation panels often incorporates energy-efficient manufacturing techniques and renewable energy sources. This holistic approach to sustainability ensures that the environmental benefits extend beyond the use phase, encompassing the entire lifecycle of the product.

Contribution to Green Building Certifications

The use of green thermal insulation panels can significantly contribute to achieving prestigious green building certifications such as LEED (Leadership in Energy and Environmental Design) and BREEAM (Building Research Establishment Environmental Assessment Method). These panels often meet or exceed the stringent requirements for energy efficiency, indoor environmental quality, and sustainable materials use set forth by these certification programs.

By incorporating these panels into building designs, architects and developers can earn valuable points towards certification, enhancing the marketability and value of their projects. This alignment with green building standards not only benefits the environment but also positions buildings for long-term sustainability and reduced operational costs.

Performance and Practical Applications

The performance of green thermal insulation panels extends beyond their environmental credentials, offering tangible benefits in various practical applications. Their versatility makes them suitable for a wide range of construction projects, from residential renovations to large-scale commercial developments.

In residential settings, these panels excel in both new constructions and retrofit projects. Homeowners benefit from improved energy efficiency, resulting in lower utility bills and enhanced comfort. The moisture-resistant properties of the panels are particularly valuable in bathrooms, kitchens, and basements, areas traditionally prone to humidity-related issues.

Commercial and Industrial Applications

In commercial and industrial buildings, green thermal insulation panels offer solutions to complex insulation challenges. Their ability to provide effective thermal regulation while managing moisture makes them ideal for facilities with strict climate control requirements, such as data centers, laboratories, and food processing plants.

The durability and fire-resistant properties of these panels also make them suitable for high-traffic areas and buildings with stringent safety regulations. Their lightweight nature facilitates easier installation in large-scale projects, potentially reducing construction time and associated costs.

Integration with Smart Building Systems

The advent of smart building technology has opened new avenues for maximizing the performance of green thermal insulation panels. Integration with building management systems allows for real-time monitoring of thermal performance and moisture levels. This data-driven approach enables proactive maintenance and optimization of building systems, ensuring that the insulation continues to perform at peak efficiency throughout its lifespan.

Some advanced panels incorporate phase-change materials, which can absorb and release heat at specific temperatures. When integrated with smart climate control systems, these panels can actively contribute to temperature regulation, further enhancing energy efficiency and occupant comfort.

Conclusion

Green thermal insulation panels represent a significant advancement in building technology, offering a powerful combination of sustainability, energy efficiency, and moisture resistance. Their ability to address multiple challenges in construction and building maintenance positions them as a crucial component in the pursuit of more sustainable and resilient architecture. As the construction industry continues to evolve towards more environmentally responsible practices, these innovative panels stand at the forefront of green building solutions, promising a future where energy conservation and structural integrity go hand in hand.

Are you ready to transform your building project with cutting-edge green thermal insulation panels? Explore our range of customizable, high-performance solutions designed to meet your specific needs. From residential to industrial applications, our panels offer unparalleled energy efficiency, moisture resistance, and sustainability. Contact us at info@sdqsc.com to discover how our green thermal insulation panels can elevate your construction project to new heights of eco-friendliness and performance.

FAQ

What makes green thermal insulation panels moisture-resistant?

These panels incorporate advanced materials and designs, such as vapor-permeable layers and hydrophobic nanotechnology coatings, which effectively manage moisture while maintaining insulation properties.

How do green thermal insulation panels contribute to energy efficiency?

They provide superior thermal resistance, reducing heat transfer and lowering the energy required for heating and cooling, resulting in significant energy savings over time.

Are green thermal insulation panels suitable for all types of buildings?

Yes, they are versatile and can be used in residential, commercial, and industrial buildings, offering benefits in various applications from new constructions to renovations.

References

1.U.S. Department of Energy. (2022). Insulation. Energy.gov.

2.U.S. Green Building Council. (2023). LEED rating system. USGBC.

3.Building Research Establishment. (2023). BREEAM.

4.International Energy Agency. (2022). Buildings: A source of enormous untapped efficiency potential. IEA.