The Science Behind Insulated Sandwich Panels' Thermal Efficiency

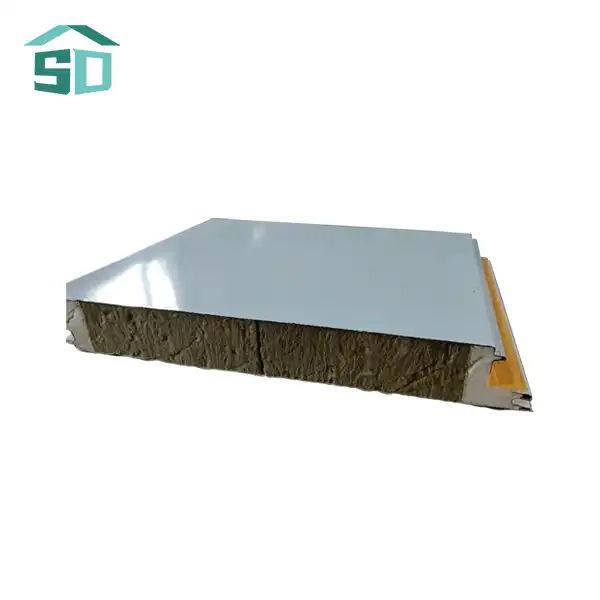

At the heart of an insulated sandwich panel's thermal performance lies its unique construction. The panels typically comprise two metal sheets—often made of aluminum, steel, or stainless steel—with a core of insulating material sandwiched between them. This core is the key to the panel's impressive thermal properties.

Common insulation materials used in these panels include polyurethane, polystyrene, rock wool, and glass wool. Each of these materials boasts low thermal conductivity, effectively minimizing heat transfer through the panel. Polyurethane, for instance, has a thermal conductivity as low as 0.022 W/mK, making it an excellent insulator.

The thickness of the insulation core plays a crucial role in determining the panel's overall thermal performance. Weifang Sandong Building Materials Co., Ltd. offers panels ranging from 50mm to 150mm in thickness, allowing for customization based on specific insulation requirements. The thicker the core, the higher the thermal resistance, or R-value, of the panel.

Thermal Bridging: A Non-Issue with Insulated Sandwich Panels

One of the significant advantages of insulated sandwich panels is their ability to minimize thermal bridging. Thermal bridges are areas in a building's envelope where heat can easily transfer, reducing overall insulation effectiveness. The continuous insulation provided by sandwich panels eliminates many of the thermal bridges commonly found in traditional construction methods, resulting in superior thermal performance across the entire structure.

Energy Savings and Environmental Impact

The exceptional thermal performance of insulated sandwich panels translates directly into significant energy savings. By maintaining a consistent internal temperature, these panels reduce the load on heating and cooling systems, leading to lower energy consumption and, consequently, reduced operational costs for building owners.

From an environmental perspective, the energy efficiency of insulated sandwich panels contributes to a reduction in greenhouse gas emissions. As buildings account for a substantial portion of global energy consumption, the widespread adoption of these high-performance panels can have a meaningful impact on our collective carbon footprint.

Sustainability in Manufacturing and Installation

Weifang Sandong Building Materials Co., Ltd. is committed to sustainability not just in the performance of their products, but also in their manufacturing and installation processes. The company utilizes recyclable materials and employs energy-efficient production techniques to minimize environmental impact.

The lightweight nature of insulated sandwich panels also contributes to their sustainability profile. Lighter materials mean reduced transportation costs and emissions, as well as less strain on the building's structural components, potentially leading to savings in other construction materials.

Versatility and Adaptability in Various Climates

One of the most compelling aspects of insulated sandwich panels is their adaptability to different climatic conditions. Whether in scorching desert heat or frigid arctic cold, these panels maintain their insulating properties, making them suitable for use in diverse geographical locations.

In hot climates, the panels' reflective outer surfaces can be designed to minimize solar heat gain, while the insulating core prevents heat from penetrating the building interior. Conversely, in cold climates, the panels effectively retain indoor heat, reducing the energy required for heating.

Customization for Optimal Performance

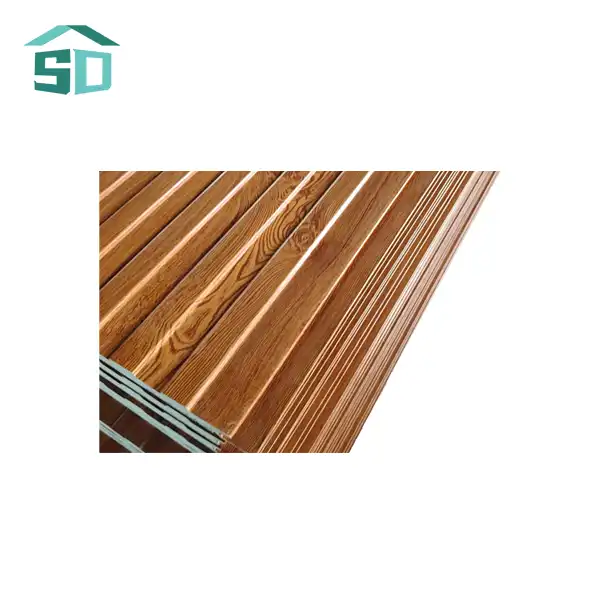

Weifang Sandong Building Materials Co., Ltd. offers a range of customization options to ensure optimal thermal performance for any project. Architects and builders can select from various insulation materials, thicknesses, and surface treatments to achieve the desired thermal properties while also meeting aesthetic requirements.

The company's panels can be finished with custom colors and surface treatments, including coating, painting, and anodizing. This versatility allows for the creation of energy-efficient buildings that don't compromise on visual appeal.

Long-Term Performance and Durability

The thermal performance of insulated sandwich panels is not just impressive—it's long-lasting. These panels are engineered to maintain their insulating properties over extended periods, ensuring consistent energy efficiency throughout the life of the building. The durable metal facings protect the insulation core from environmental factors, preserving its effectiveness year after year.

Moreover, the panels' resistance to corrosion and ease of maintenance contribute to their long-term performance. With proper care, insulated sandwich panels can continue to deliver exceptional thermal efficiency for decades, making them a wise investment for sustainable building projects.

Conclusion

Insulated sandwich panels have earned their place at the forefront of thermal performance in the construction industry. Their unique construction, customizable properties, and long-term durability make them an ideal choice for energy-efficient buildings across various climates and applications. As the world continues to prioritize sustainable construction practices, these panels offer a solution that balances thermal efficiency, environmental responsibility, and aesthetic flexibility.

For those looking to leverage the superior thermal performance of insulated sandwich panels in their next construction project, Weifang Sandong Building Materials Co., Ltd. stands ready to provide expert guidance and top-quality products. To learn more about our range of insulated sandwich panels and how they can benefit your building's thermal performance, please contact us at info@sdqsc.com.

FAQ

How do insulated sandwich panels compare to traditional insulation methods?

Insulated sandwich panels offer superior thermal performance compared to many traditional methods. They provide continuous insulation, minimize thermal bridging, and often result in thinner wall assemblies while achieving higher R-values.

Are insulated sandwich panels suitable for retrofitting existing buildings?

Yes, these panels can be an excellent option for retrofitting, offering improved insulation without significant structural changes. They're particularly useful for industrial and commercial building upgrades.

What is the typical lifespan of an insulated sandwich panel?

With proper installation and maintenance, insulated sandwich panels can last 30-50 years or more, maintaining their thermal performance throughout their lifespan.

References

1.U.S. Department of Energy. (2022). Insulation Materials. Energy.gov.

2.Sustainability in Construction. (2021). World Green Building Council.

3.Thermal Bridging in External Walls. (2023). Building Science Corporation.

4.Energy Efficiency in Buildings. (2022). International Energy Agency.