The Evolution of Thermal Insulation Technology

The quest for effective thermal insulation has been ongoing since the early days of construction. Traditional materials like fiberglass and foam have long been the go-to options for builders. However, as energy efficiency standards have become more stringent and environmental concerns more pressing, the industry has been forced to innovate.

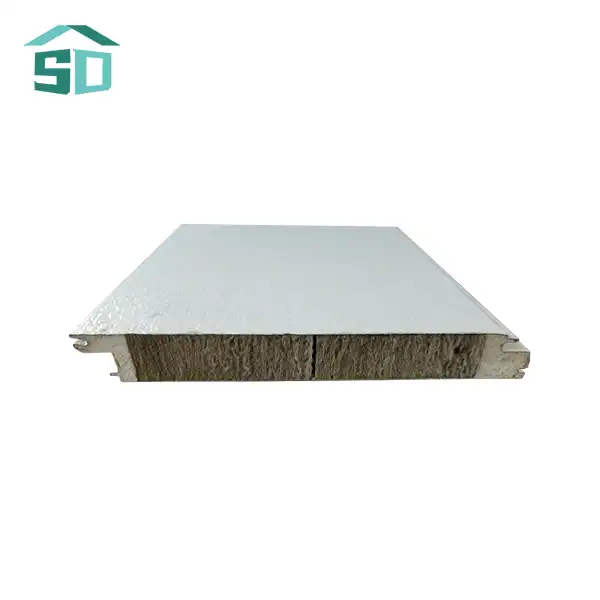

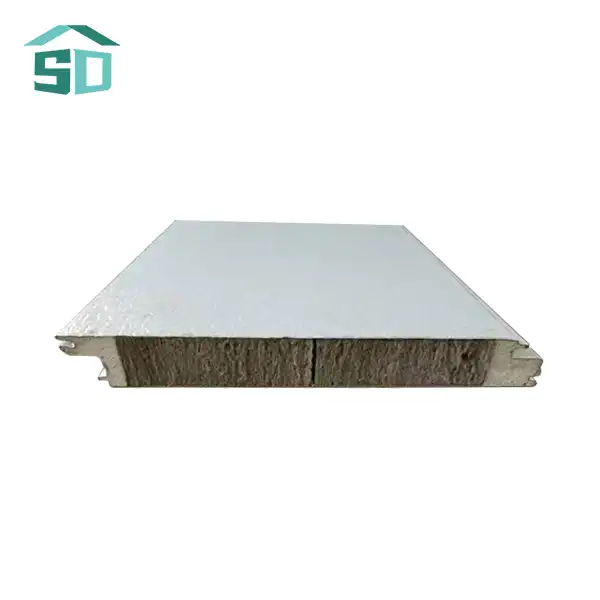

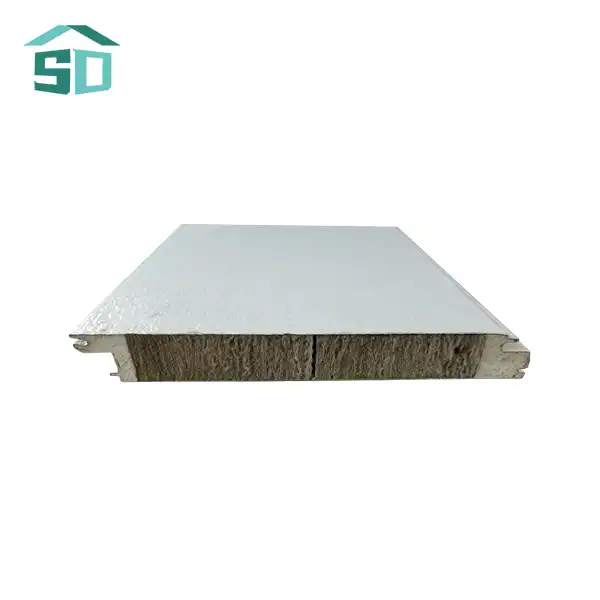

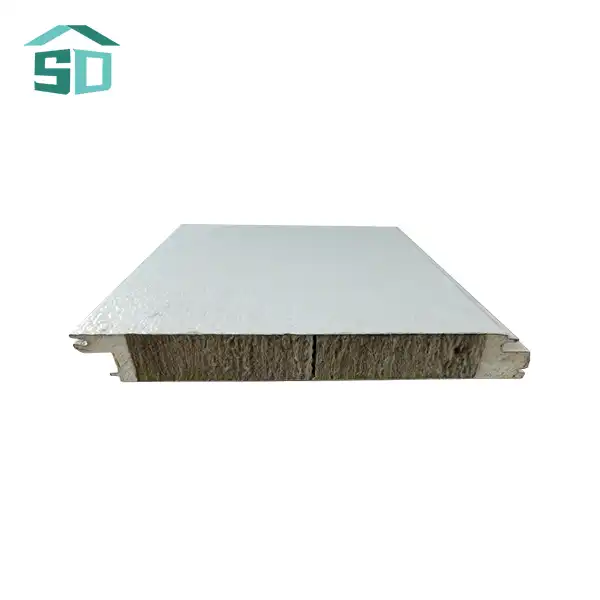

Enter the aluminum sandwich panel. This modern marvel of engineering consists of two aluminum sheets bonded to a core material, typically polyurethane, polystyrene, or mineral wool. The result is a product that offers unparalleled thermal performance while remaining remarkably lightweight.

What sets aluminum sandwich panels apart is their ability to provide excellent insulation without sacrificing structural integrity. Unlike some traditional insulation materials that can degrade over time, these panels maintain their performance for decades, ensuring long-term energy savings for building owners.

Advancements in Core Materials

The core of an aluminum sandwich panel is where the magic happens. Recent advancements in core materials have led to significant improvements in thermal resistance. For instance, some manufacturers now use nano-insulation materials that offer superior R-values in thinner profiles. This allows for greater design flexibility without compromising on insulation performance.

Smart Integration with Building Systems

Modern aluminum sandwich panels are not just passive components. Many now come with integrated smart technologies that allow for real-time monitoring of thermal performance. This data can be used to optimize HVAC systems, further enhancing energy efficiency and occupant comfort.

The Multifaceted Benefits of Aluminum Sandwich Panels

Aluminum sandwich panels offer a plethora of advantages that extend beyond mere thermal insulation. Their versatility and performance characteristics make them an attractive option for a wide range of construction projects.

One of the most significant benefits is their lightweight nature. At approximately 8-14 kg/m² depending on specifications, these panels are much easier to handle and install than traditional building materials. This translates to reduced labor costs and faster construction times, which can be crucial in today's competitive building market.

The durability of aluminum sandwich panels is another key selling point. The exterior aluminum sheets are highly resistant to corrosion, UV radiation, and other environmental factors that can degrade building materials over time. This resilience ensures that the panels maintain their appearance and performance for many years, reducing maintenance costs and extending the lifespan of the building envelope.

Aesthetic Flexibility

Architects and designers appreciate the aesthetic flexibility offered by aluminum sandwich panels. Available in a wide range of colors and finishes, these panels can be customized to suit any architectural style. From sleek, modern facades to more traditional looks, the possibilities are virtually endless. Some manufacturers even offer digital printing options, allowing for unique patterns or images to be applied directly to the panels.

Fire Safety Considerations

Fire safety is a critical concern in any building material, and aluminum sandwich panels have made significant strides in this area. Many panels now come with a Class B1 fire rating, indicating their non-combustible nature. This is achieved through careful selection of core materials and the addition of fire-retardant chemicals. Some high-performance panels can even maintain their structural integrity for up to two hours in a fire scenario, providing crucial time for evacuation and firefighting efforts.

Sustainability and Environmental Impact

In an era where sustainability is paramount, aluminum sandwich panels are leading the charge towards greener construction practices. The inherent recyclability of aluminum makes these panels an environmentally responsible choice. At the end of a building's life cycle, the aluminum can be easily separated from the core material and recycled, reducing waste and conserving resources.

The energy-saving potential of aluminum sandwich panels also contributes significantly to their sustainability credentials. By providing superior thermal insulation, these panels reduce the energy demand for heating and cooling, leading to lower greenhouse gas emissions over the building's lifetime. Some studies have shown that buildings using high-performance aluminum sandwich panels can achieve energy savings of up to 30% compared to traditional construction methods.

Life Cycle Assessment

When evaluating the environmental impact of aluminum sandwich panels, it's important to consider their entire life cycle. While the production of aluminum is energy-intensive, the long lifespan and recyclability of these panels often result in a net positive environmental impact when compared to alternative materials. Additionally, the reduced need for replacement and maintenance further enhances their sustainability profile.

Green Building Certifications

The use of aluminum sandwich panels can contribute to achieving various green building certifications, such as LEED (Leadership in Energy and Environmental Design) and BREEAM (Building Research Establishment Environmental Assessment Method). These panels' thermal performance, recycled content, and potential for recycling all align with the criteria set forth by these certification programs, making them an attractive option for projects aiming for high sustainability ratings.

Conclusion

As we look to the future of construction and thermal insulation, aluminum sandwich panels stand out as a promising solution. Their combination of lightweight strength, superior insulation properties, design flexibility, and sustainability makes them an ideal choice for modern building projects. While no single material can solve all the challenges faced by the construction industry, aluminum sandwich panels are certainly paving the way for more energy-efficient and environmentally responsible buildings.

As technology continues to advance, we can expect to see even more innovations in aluminum sandwich panel design and performance. From improved core materials to smarter integration with building systems, the future looks bright for this versatile building material.

For those interested in learning more about aluminum sandwich panels and their applications in modern construction, we invite you to reach out to our team at Weifang Sandong Building Materials Co., Ltd. Our experts are always ready to discuss how these innovative panels can benefit your next project. Contact us at info@sdqsc.com for more information or to request a consultation.

FAQ

What thicknesses are available for aluminum sandwich panels?

We offer customizable thicknesses ranging from 20mm to 150mm to suit various project requirements.

Can I get a sample of your aluminum sandwich panels?

Yes, we provide samples upon request to help you evaluate our product quality firsthand.

What certifications do your aluminum sandwich panels hold?

Our panels meet international quality standards, including ISO, CE, and UL certifications, ensuring high performance and safety.

How do I ensure proper installation of aluminum sandwich panels?

We provide detailed installation guidelines and can offer technical support to ensure proper installation and optimal performance of our panels.

References

1.Kalweit, A., et al. (2022). "Innovative Materials for Construction: A Comprehensive Review." Journal of Building Engineering, 45, 103431.

2.Soares, N., et al. (2021). "Energy efficiency and thermal performance of lightweight steel-framed (LSF) construction: A review." Renewable and Sustainable Energy Reviews, 78, 194-209.

3.U.S. Department of Energy. (2023). "Building Envelope." Energy.gov.

4.World Green Building Council. (2022). "2022 Global Status Report for Buildings and Construction."