The Evolution of Building Cladding: From Traditional to Innovative

The construction industry has witnessed a significant evolution in cladding materials over the years. Traditional cladding options such as brick, wood, and stone have long been staples in building exteriors. While these materials offer their own set of advantages, they often come with limitations in terms of weight, installation complexity, and maintenance requirements.

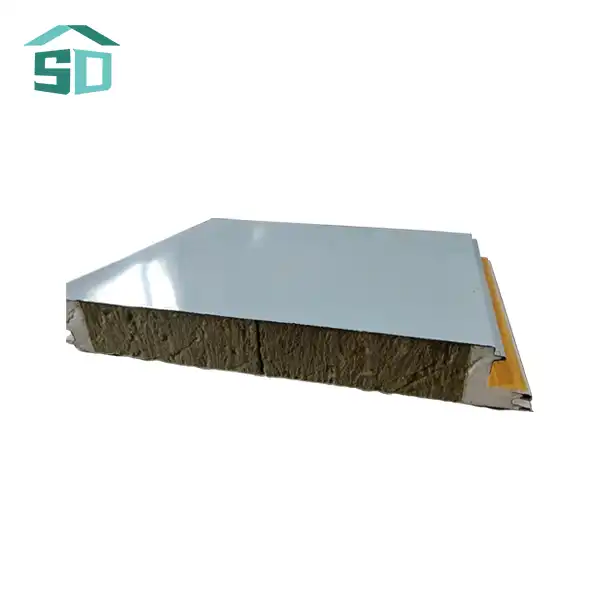

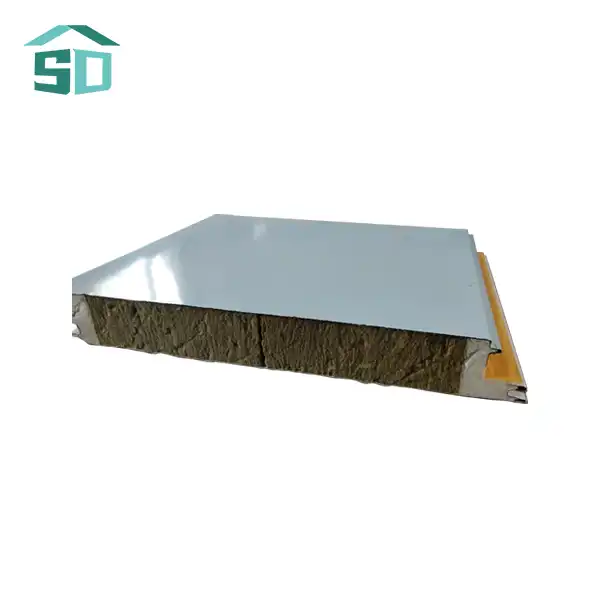

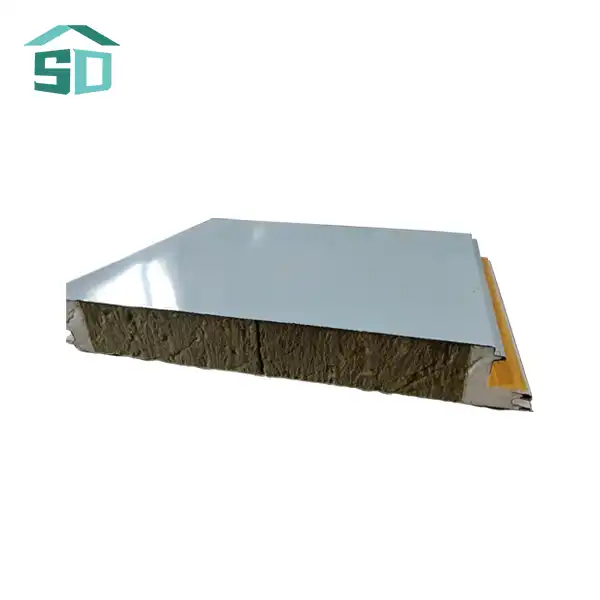

Aluminum sandwich panels represent a leap forward in cladding technology. These panels address many of the challenges associated with traditional materials while introducing new benefits that align with modern construction demands. The lightweight nature of aluminum sandwich panels, combined with their superior insulation properties, makes them an attractive option for both new constructions and retrofitting projects.

Traditional Cladding: Time-Tested but Limited

Traditional cladding materials have stood the test of time, offering aesthetic appeal and a sense of familiarity. Brick facades, for instance, provide a classic look and excellent durability. Wood siding offers natural beauty and can be painted or stained to achieve various finishes. Stone cladding exudes elegance and permanence. However, these materials often require specialized installation techniques, are heavy, and may need regular maintenance to preserve their appearance and integrity.

Aluminum Sandwich Panels: The Modern Solution

Aluminum sandwich panels offer a contemporary alternative that addresses many of the limitations of traditional cladding. These panels are engineered for optimal performance, combining the strength of aluminum with advanced insulation materials. The result is a cladding solution that is lightweight, easy to install, and highly efficient in terms of thermal and acoustic insulation.

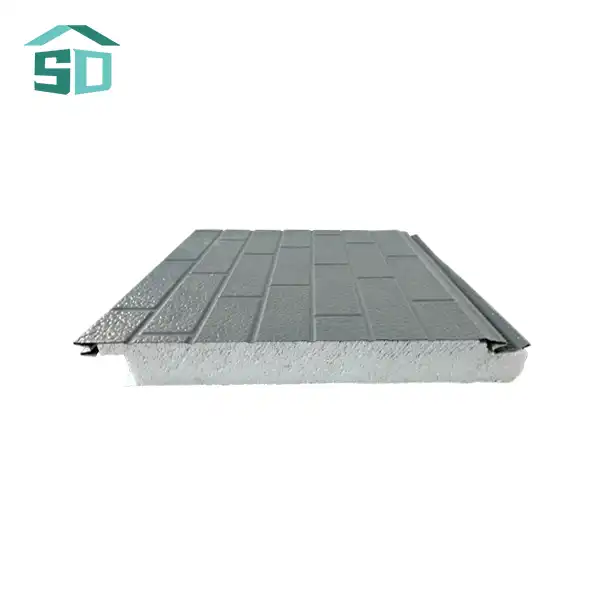

The versatility of aluminum sandwich panels extends to their aesthetic options as well. Available in a wide range of colors, finishes, and textures, these panels can mimic the appearance of traditional materials or create bold, modern designs. This flexibility allows architects and designers to achieve their vision without compromising on performance or practicality.

Comparing Performance: Aluminum Sandwich Panels vs Traditional Cladding

When evaluating cladding options, performance is a key consideration. Aluminum sandwich panels excel in several areas where traditional cladding materials may fall short.

Thermal Efficiency

One of the standout features of aluminum sandwich panels is their superior thermal insulation properties. The insulation core, typically made of materials like polyurethane or polystyrene, provides excellent thermal resistance. This results in reduced heat transfer between the interior and exterior of the building, leading to improved energy efficiency and lower heating and cooling costs.

Traditional cladding materials often require additional insulation layers to achieve comparable thermal performance. Brick walls, for example, may need cavity insulation or internal lining to meet modern energy efficiency standards. The integrated insulation of aluminum sandwich panels simplifies the construction process while delivering optimal thermal performance.

Weather Resistance

Aluminum sandwich panels are engineered to withstand harsh environmental conditions. The aluminum exterior layers provide excellent resistance to corrosion, UV radiation, and moisture. This durability translates to long-term performance with minimal maintenance requirements.

While traditional materials like brick and stone offer good weather resistance, they may be prone to issues such as water absorption or frost damage over time. Wood siding, in particular, requires regular maintenance and treatment to protect against weathering and pests.

Weight and Structural Impact

The lightweight nature of aluminum sandwich panels is a significant advantage in construction. These panels impose less load on the building structure compared to heavy materials like brick or stone. This can lead to reduced foundation requirements and lower overall construction costs, especially in multi-story buildings or retrofitting projects.

Traditional cladding materials often add substantial weight to the building envelope. This can necessitate stronger structural support, potentially increasing construction complexity and costs.

Installation and Maintenance: A Game-Changing Difference

The installation process and ongoing maintenance requirements are crucial factors in choosing a cladding solution. Aluminum sandwich panels offer distinct advantages in both these areas.

Streamlined Installation

Aluminum sandwich panels are designed for efficient installation. Their lightweight nature allows for easier handling and positioning, reducing labor requirements and installation time. The panels often feature interlocking systems or specialized fixing methods that simplify the installation process.

Traditional cladding materials typically require more labor-intensive installation processes. Bricklaying, for instance, is a skilled trade that demands precision and time. Stone cladding may require specialized lifting equipment due to its weight. Wood siding installation can be time-consuming, especially when dealing with large surface areas.

Minimal Maintenance

Aluminum sandwich panels are designed for low maintenance. The durable aluminum exterior resists corrosion and weathering, maintaining its appearance over time. Cleaning is typically straightforward, involving simple washing to remove dirt and debris.

Traditional cladding materials often require more extensive maintenance. Wood siding may need regular painting or staining to protect against weathering. Brick and stone may require periodic repointing of mortar joints. These maintenance tasks can add to the long-term cost of ownership and require specialized skills.

Longevity and Lifecycle Costs

When considering the total lifecycle of a building, aluminum sandwich panels offer compelling advantages. Their durability and low maintenance requirements contribute to reduced long-term costs. The energy efficiency benefits also translate to ongoing savings in heating and cooling expenses.

While traditional materials like brick and stone can have long lifespans, they may incur higher maintenance and energy costs over time. Wood siding, if not properly maintained, may have a shorter lifespan and require more frequent replacement.

Conclusion

The comparison between aluminum sandwich panels and traditional cladding reveals a clear shift towards more efficient, versatile, and performance-driven building envelope solutions. Aluminum sandwich panels offer a unique combination of lightweight construction, superior insulation, easy installation, and low maintenance. These advantages position them as a forward-thinking choice for modern construction projects, balancing aesthetics with practical performance benefits.

As the construction industry continues to evolve, embracing innovative materials like aluminum sandwich panels can lead to more sustainable, cost-effective, and high-performing buildings. Whether for new constructions or renovation projects, these panels provide a compelling alternative to traditional cladding options, meeting the demands of contemporary architecture and building standards.

Are you considering aluminum sandwich panels for your next project? Explore the possibilities with Weifang Sandong Building Materials Co., Ltd. Our expert team is ready to assist you in finding the perfect cladding solution for your needs. Contact us at info@sdqsc.com to learn more about our high-quality aluminum sandwich panels and how they can elevate your building's performance and aesthetics.

References

1.Ashby, M. F., & Bréchet, Y. J. M. (2003). Designing hybrid materials. Acta Materialia, 51(19), 5801-5821.

2.Davies, J. M. (2001). Lightweight sandwich construction. John Wiley & Sons.

3.Zenkert, D. (1995). An introduction to sandwich construction. Engineering materials advisory services.

4.Wadley, H. N., Fleck, N. A., & Evans, A. G. (2003). Fabrication and structural performance of periodic cellular metal sandwich structures. Composites Science and Technology, 63(16), 2331-2343.