Innovative Materials Revolutionizing Waterproof Exterior Wall Panels

Fiber Cement: The Versatile Performer

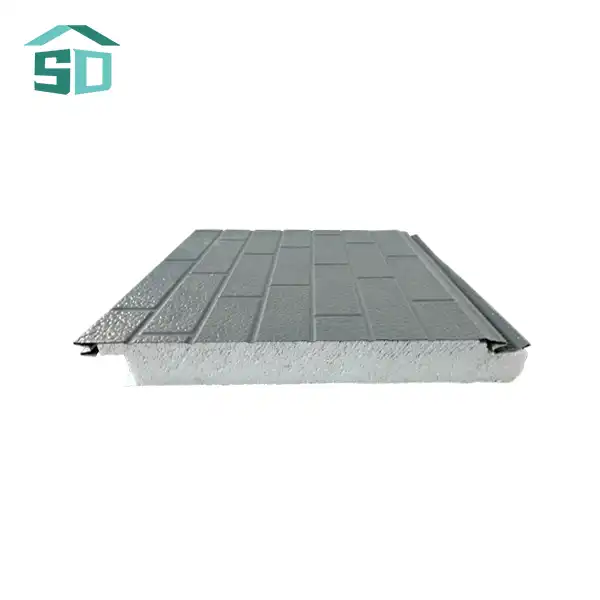

Fiber cement has emerged as a frontrunner in the realm of waterproof exterior wall panels. This innovative material combines the strength of cement with the flexibility of cellulose fibers, resulting in a product that boasts exceptional durability and water resistance. Manufacturers of waterproof exterior wall panels have refined the production process to create panels that mimic the appearance of natural materials like wood or stone while offering superior protection against moisture intrusion.

The unique composition of fiber cement allows it to withstand extreme weather conditions without warping, rotting, or deteriorating. This resilience makes it an ideal choice for regions prone to high humidity, heavy rainfall, or coastal areas where salt spray can be a concern. Additionally, fiber cement waterproof exterior wall panels are fire-resistant, adding an extra layer of safety to buildings.

One of the most appealing aspects of fiber cement panels is their versatility in design. They can be manufactured to replicate a wide range of textures and finishes, from smooth modern surfaces to rustic wood grains. This flexibility allows architects and designers to achieve their desired aesthetic without compromising on the waterproofing capabilities of the exterior cladding.

Metal Panels: Sleek and Impenetrable

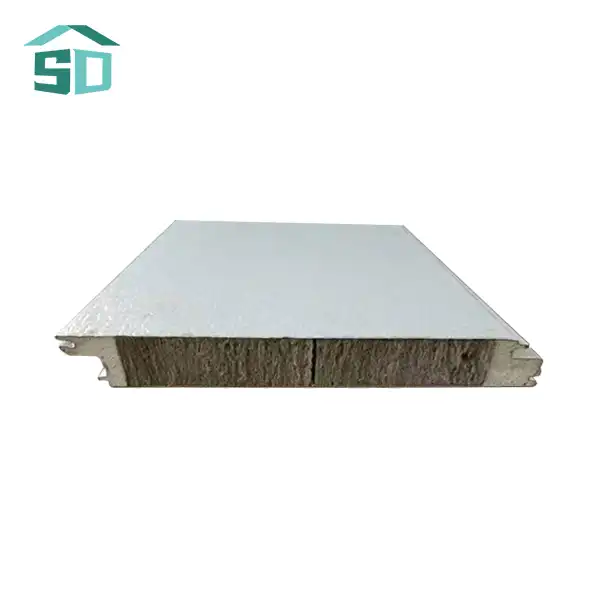

Metal waterproof exterior wall panels, particularly those made from aluminum or steel, have gained popularity for their sleek appearance and exceptional water-resistant properties. These panels are engineered to create a virtually impenetrable barrier against moisture, making them an excellent choice for areas with challenging weather patterns.

Advanced coating technologies have further enhanced the performance of metal waterproof exterior wall panels. Fluoropolymer coatings, for instance, not only provide additional protection against corrosion and UV radiation but also offer a wide range of color options. This allows for creative freedom in design while maintaining the panel's core functionality.

The inherent strength of metal panels contributes to their longevity and low maintenance requirements. When properly installed, these waterproof exterior wall panels can last for decades with minimal upkeep, making them a cost-effective solution in the long run. Their ability to reflect heat also contributes to improved energy efficiency in buildings, potentially reducing cooling costs during warmer months.

High-Density Polyethylene (HDPE): The Lightweight Champion

HDPE waterproof exterior wall panels represent a modern approach to building envelope protection. This synthetic material offers a unique combination of lightweight properties and robust water resistance, making it an attractive option for both new construction and renovation projects.

One of the standout features of HDPE panels is their resistance to UV radiation. This quality ensures that the panels maintain their color and structural integrity even after prolonged exposure to sunlight, a crucial factor for exterior applications. The non-porous nature of HDPE also means that these waterproof exterior wall panels are inherently resistant to mold, mildew, and bacteria growth, contributing to a healthier building environment.

Installation of HDPE panels is often simpler and faster compared to traditional materials, thanks to their lightweight nature. This can lead to reduced labor costs and shorter construction timelines. Moreover, HDPE is a recyclable material, aligning with the growing demand for sustainable building practices.

Factors Influencing the Selection of Waterproof Exterior Wall Panels

Climate Considerations for Optimal Performance

The effectiveness of waterproof exterior wall panels can vary significantly based on the local climate. In regions with high rainfall or humidity, panels with superior moisture resistance and vapor permeability are crucial. For coastal areas, resistance to salt corrosion becomes a primary concern. In contrast, areas with extreme temperature fluctuations require panels that can withstand thermal expansion and contraction without compromising their waterproof integrity.

Manufacturers of waterproof exterior wall panels often provide specific product lines tailored to different climate zones. For instance, panels designed for tropical climates may incorporate additional UV protection and mold resistance, while those for colder regions might focus on thermal insulation properties alongside waterproofing.

It's essential to consider not just the average weather conditions but also extreme weather events when selecting waterproof exterior wall panels. Panels that can withstand high wind loads, for example, are crucial in hurricane-prone areas. The ability to maintain waterproof integrity under such conditions can significantly impact the long-term performance and durability of the building envelope.

Aesthetic Versatility and Design Integration

While the primary function of waterproof exterior wall panels is protection, their visual impact on a building's appearance cannot be overstated. Modern manufacturing techniques have greatly expanded the aesthetic options available, allowing these functional elements to become key components of a building's architectural expression.

Waterproof exterior wall panels now come in a vast array of colors, textures, and patterns. Some manufacturers offer customization options, allowing architects to create unique facades that align perfectly with their design vision. This versatility enables the seamless integration of waterproof panels into various architectural styles, from sleek modern designs to more traditional aesthetics.

The ability to mix and match different panel styles and finishes has opened up new possibilities in facade design. For instance, combining metal panels with fiber cement can create interesting visual contrasts while maintaining consistent waterproofing performance across the entire building envelope. This flexibility allows for creative expression without compromising on the essential protective functions of the exterior cladding.

Long-Term Cost Efficiency and Maintenance Requirements

When evaluating waterproof exterior wall panels, it's crucial to look beyond the initial installation costs and consider the long-term economic implications. High-quality panels may come with a higher upfront cost but can offer significant savings over time through reduced maintenance needs and extended lifespan.

Maintenance requirements vary widely among different types of waterproof exterior wall panels. Some materials, like certain metal panels, may require minimal upkeep beyond occasional cleaning. Others might need periodic resealing or repainting to maintain their waterproof properties. Understanding these ongoing maintenance needs is essential for accurately estimating the total lifecycle cost of the cladding system.

Energy efficiency is another factor that can significantly impact the long-term cost-effectiveness of waterproof exterior wall panels. Panels with good insulating properties can contribute to reduced heating and cooling costs, potentially offsetting their initial cost over time. Some advanced panel systems even incorporate features like integrated ventilation or solar reflectivity, further enhancing their energy performance.

Installation Techniques for Maximum Waterproofing Efficacy

Proper Sealing and Joint Management

The effectiveness of waterproof exterior wall panels heavily relies on proper installation techniques, particularly when it comes to sealing and joint management. Even the highest quality panels can fail to protect against water ingress if joints and seams are not adequately addressed. Professional installers employ various methods to ensure a watertight seal between panels and at critical junctions.

One common approach is the use of specialized sealants designed specifically for the material of the waterproof exterior wall panels. These sealants must be compatible with the panel material and capable of withstanding the same environmental conditions. For metal panels, for instance, silicone-based sealants are often preferred due to their durability and flexibility.

Advanced installation systems may incorporate interlocking panel designs or hidden fastening systems that minimize the number of exposed joints. Some waterproof exterior wall panel systems feature built-in drainage planes or pressure-equalization chambers, which help manage any water that might penetrate the outer surface, directing it safely away from the building structure.

Integration with Building Envelope Systems

Waterproof exterior wall panels are just one component of a building's overall moisture management strategy. Their effectiveness is maximized when they are properly integrated with other elements of the building envelope, such as windows, doors, and roof systems. This integration requires careful planning and execution to ensure continuity of the water-resistant barrier across all transitions.

Flashing details are particularly critical in these transition areas. Installers of waterproof exterior wall panels must pay close attention to how the panels interface with window and door openings, ensuring that water is directed away from potential entry points. Similarly, the integration of panels with roof edges and parapets requires specialized flashing techniques to prevent water from infiltrating at these vulnerable junctions.

Some advanced waterproof exterior wall panel systems come with pre-engineered solutions for common architectural details, simplifying the integration process and reducing the risk of installation errors. These might include pre-formed corner pieces, specialized trim elements, or integrated gutter systems designed to work seamlessly with the panel system.

Quality Control and Post-Installation Inspection

The installation of waterproof exterior wall panels is not complete without rigorous quality control measures and post-installation inspections. These steps are crucial in ensuring that the panels will perform as intended and provide long-lasting protection against water intrusion.

During installation, regular checks should be conducted to verify that panels are being installed according to manufacturer specifications. This includes ensuring proper panel alignment, correct fastener placement, and appropriate application of sealants. Some manufacturers of waterproof exterior wall panels offer on-site support or training programs to help installers achieve the best possible results.

Post-installation inspections may involve visual checks for any signs of misalignment or damage, as well as more sophisticated testing methods. Water spray tests, for example, can be used to simulate rain conditions and identify any potential leakage points. Thermal imaging cameras can detect areas of moisture accumulation or thermal bridging that might not be visible to the naked eye.

Conclusion

The selection and installation of waterproof exterior wall panels play a pivotal role in ensuring the longevity and performance of buildings. From innovative materials like fiber cement and HDPE to traditional options like metal, each type of panel offers unique benefits suited to different architectural needs and environmental conditions. Partnering with a trusted waterproof exterior wall panels factory provides access to high-quality products, technical expertise, and customized solutions that maximize durability, energy efficiency, and long-term cost performance. Proper installation techniques, including meticulous sealing and integration with other building envelope components, are crucial for achieving optimal waterproofing results.

At Weifang Sandong Building Materials Co., Ltd., we understand the importance of high-quality waterproof exterior wall panels in protecting and enhancing your building. Our range of products combines cutting-edge technology with aesthetic appeal, offering solutions that are both functional and visually striking. Whether you're looking for panels that mimic natural materials or seeking ultra-modern designs, our team can help you find the perfect match for your project. For expert advice on selecting and installing waterproof exterior wall panels, don't hesitate to reach out to us at info@sdqsc.com.

FAQ

What are the main benefits of using waterproof exterior wall panels?

Waterproof exterior wall panels offer excellent protection against moisture intrusion, enhance energy efficiency, and provide aesthetic versatility. They are durable, low-maintenance, and can significantly improve a building's overall performance and longevity.

How long do waterproof exterior wall panels typically last?

The lifespan of waterproof exterior wall panels varies depending on the material and environmental conditions. High-quality panels can last 30-50 years or more with proper maintenance.

Can waterproof exterior wall panels be installed over existing siding?

In many cases, yes. However, it's crucial to assess the condition of the existing structure and ensure proper preparation before installation. Consulting with a professional is recommended for the best results.

References

1. Building Science Corporation. (2021). "Water Management in Building Envelopes."

2. National Institute of Building Sciences. (2022). "Whole Building Design Guide: Building Envelope Design Guide."

3. American Society for Testing and Materials. (2020). "ASTM E2128-20 Standard Guide for Evaluating Water Leakage of Building Walls." ASTM International.