The Structure and Composition of Aluminum Sandwich Panels

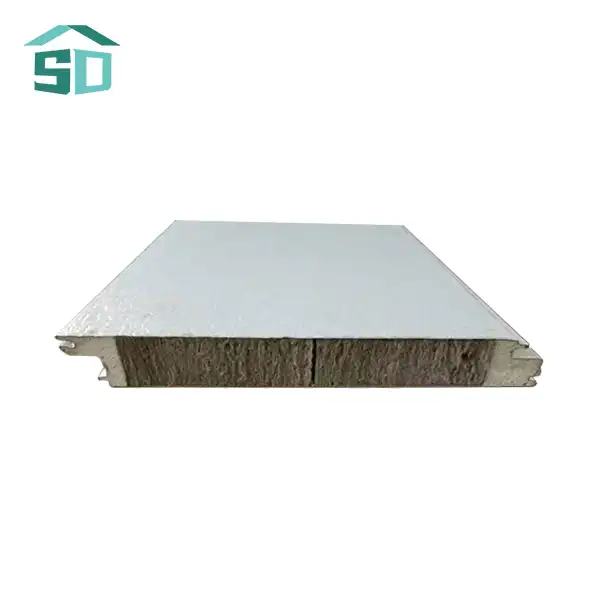

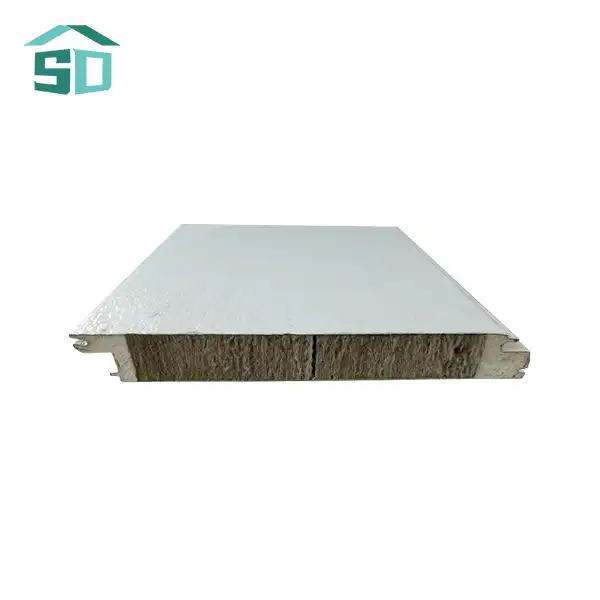

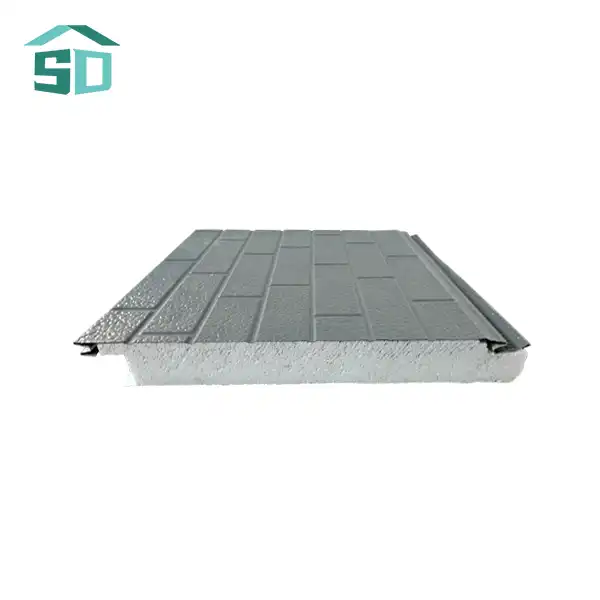

Anatomy of an Aluminum Sandwich Panel

Aluminum sandwich panels are engineered composite materials designed to optimize strength, weight, and performance. The typical structure consists of three main components:

- Face Sheets: Two thin layers of aluminum alloy form the outer surfaces of the panel, providing strength and rigidity.

- Core Material: A lightweight core, often made of materials like polyurethane foam, polystyrene, or aluminum honeycomb, fills the space between the face sheets.

- Adhesive Layer: A high-strength adhesive bonds the face sheets to the core, ensuring structural integrity and load distribution.

This layered configuration creates a panel with exceptional strength-to-weight ratio and vibration dampening capabilities. The face sheets contribute to the overall stiffness, while the core material plays a crucial role in absorbing and dissipating vibrational energy.

Material Properties and Their Impact on Vibration Dampening

The vibration dampening effectiveness of aluminum sandwich panels stems from the unique properties of their constituent materials:

- Aluminum Face Sheets: Aluminum alloys offer a combination of low density, high strength, and excellent corrosion resistance. These properties allow the face sheets to withstand external forces while maintaining the panel's overall lightweight nature.

- Core Material: The core's composition significantly influences the panel's vibration dampening performance. Materials like polyurethane foam exhibit viscoelastic behavior, which enables them to convert vibrational energy into heat through internal friction.

- Adhesive Layer: The adhesive not only bonds the components together but also contributes to energy dissipation by allowing slight relative movement between the face sheets and core during vibration.

The synergy between these materials creates a composite structure that effectively attenuates vibrations across a wide frequency range. This makes aluminum sandwich panels particularly useful in applications where vibration control is critical, such as in aerospace, automotive, and construction industries.

Mechanisms of Vibration Dampening in Aluminum Sandwich Panels

Energy Dissipation Through Material Deformation

One of the primary mechanisms by which aluminum sandwich panels dampen vibrations is through energy dissipation via material deformation. When subjected to vibrational forces, the panel undergoes microscopic deformations in its structure. These deformations occur primarily in the core material and the adhesive layers.

The viscoelastic properties of the core material, such as polyurethane foam, allow it to deform under stress and then slowly return to its original shape. During this process, a portion of the vibrational energy is converted into heat through internal friction within the material. This conversion of mechanical energy to thermal energy effectively reduces the amplitude of vibrations.

Additionally, the adhesive layer between the face sheets and the core undergoes shear deformation during vibration. This deformation also contributes to energy dissipation, further enhancing the panel's dampening capabilities.

Impedance Mismatch and Wave Reflection

Another crucial mechanism in vibration dampening is the concept of impedance mismatch between the different layers of the aluminum sandwich panel. Acoustic impedance is a measure of how much a material resists the propagation of sound waves. The significant difference in acoustic impedance between the aluminum face sheets and the core material creates an interface that reflects a portion of the incoming vibrational waves.

When vibrations encounter the interface between the face sheet and the core, some of the energy is reflected due to this impedance mismatch. This reflection reduces the amount of vibrational energy transmitted through the panel. Moreover, the multiple interfaces within the sandwich structure (face sheet-adhesive-core-adhesive-face sheet) create a series of reflections that further attenuate the vibration.

The combination of energy dissipation through material deformation and wave reflection due to impedance mismatch results in a highly effective vibration dampening system. This multi-faceted approach allows aluminum sandwich panels to mitigate vibrations across a broad spectrum of frequencies, making them versatile solutions for various applications requiring noise and vibration control.

Applications and Benefits of Vibration Dampening in Aluminum Sandwich Panels

Architectural and Construction Applications

In the realm of architecture and construction, aluminum sandwich panels with vibration dampening properties offer numerous advantages:

- Noise Reduction: The panels' ability to absorb and dissipate vibrational energy translates into superior sound insulation for buildings. This is particularly beneficial in urban environments or near high-traffic areas.

- Structural Stability: By reducing vibrations, these panels contribute to the overall stability of structures, potentially extending their lifespan and reducing maintenance requirements.

- Comfort Enhancement: In residential and commercial buildings, the dampening properties create more comfortable living and working spaces by minimizing the transmission of external vibrations.

Architects and builders increasingly choose aluminum sandwich panels for their versatility and performance in facades, roofing, and interior partitions. The panels' lightweight nature also allows for easier handling and installation, reducing construction time and costs.

Transportation and Industrial Uses

The vibration dampening capabilities of aluminum sandwich panels make them invaluable in transportation and industrial applications:

- Automotive Industry: Used in vehicle body panels and interior components to reduce road noise and vibrations, enhancing passenger comfort.

- Aerospace: Employed in aircraft interiors and structural components to minimize vibrations and noise, improving passenger experience and reducing fatigue on aircraft structures.

- Marine Applications: Utilized in ship and boat construction to dampen engine vibrations and improve onboard comfort.

- Industrial Machinery: Incorporated into machine enclosures and foundations to reduce operational vibrations, leading to improved precision and reduced wear on equipment.

The ability of aluminum sandwich panels to combine lightweight properties with effective vibration dampening makes them an attractive solution for industries where weight reduction and performance optimization are crucial.

Energy Efficiency and Environmental Considerations

Beyond their primary function of vibration dampening, aluminum sandwich panels contribute to energy efficiency and environmental sustainability:

- Thermal Insulation: The core materials used in these panels often provide excellent thermal insulation, reducing heating and cooling costs in buildings.

- Recyclability: Aluminum is highly recyclable, and many core materials can also be recycled or repurposed, aligning with sustainable construction practices.

- Longevity: The durability and corrosion resistance of aluminum sandwich panels extend the lifespan of structures, reducing the need for frequent replacements and associated environmental impacts.

These environmental benefits, coupled with their performance characteristics, position aluminum sandwich panels as a forward-thinking solution in the construction and manufacturing industries.

Conclusion

The science behind aluminum sandwich panel vibration dampening reveals a sophisticated interplay of material properties and structural design. These panels leverage the principles of energy dissipation, impedance mismatch, and wave reflection to effectively mitigate vibrations across various applications. Their ability to combine lightweight construction with robust performance makes them invaluable in architecture, transportation, and industrial settings. As the demand for energy-efficient and environmentally conscious building materials grows, aluminum sandwich panels stand out as a versatile and sustainable solution.

At Weifang Sandong Building Materials, we're committed to harnessing the full potential of aluminum sandwich panels to meet your specific needs. Our advanced production lines and rigorous quality control ensure that every panel delivers optimal vibration dampening performance. Whether you're working on a residential complex, office building, or industrial facility, our panels offer the perfect blend of functionality and aesthetics. Ready to elevate your next project with cutting-edge aluminum sandwich panels? Contact us at info@sdqsc.com to explore how our solutions can bring your vision to life.

FAQ

How do aluminum sandwich panels compare to traditional building materials in terms of vibration dampening?

Aluminum sandwich panels generally outperform traditional materials like solid concrete or steel in vibration dampening due to their composite structure and energy-dissipating core.

Can the vibration dampening properties of aluminum sandwich panels be customized?

Yes, the dampening properties can be tailored by adjusting the core material, thickness, and overall panel composition to meet specific project requirements.

Are there any limitations to using aluminum sandwich panels for vibration dampening?

While highly effective, these panels may have limitations in extremely high-temperature environments or under very high loads. It's important to consult with experts for specific application suitability.

References

1.Vinson, J. R. (2018). The Behavior of Sandwich Structures of Isotropic and Composite Materials. Routledge.

2.Zenkert, D. (1997). The Handbook of Sandwich Construction. Engineering Materials Advisory Services Ltd.

3.Ashby, M. F. (2011). Materials Selection in Mechanical Design. Butterworth-Heinemann.

4.Fahy, F., & Gardonio, P. (2007). Sound and Structural Vibration: Radiation, Transmission and Response. Academic Press.

5.Davies, J. M. (2001). Lightweight Sandwich Construction. Blackwell Science.