- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

PU Steel Sandwich Panels for Cold Storage Rooms

Steel PU sandwich panels have revolutionized the construction of cold storage rooms, offering unparalleled insulation and durability. These innovative panels combine a robust steel exterior with a polyurethane (PU) core, creating a formidable barrier against temperature fluctuations. By utilizing steel PU sandwich panels, cold storage facilities can maintain precise temperature control while minimizing energy consumption. The panels' superior thermal properties, coupled with their structural strength, make them an ideal choice for businesses seeking efficient and long-lasting cold storage solutions. From food processing plants to pharmaceutical storage, steel PU sandwich panels are transforming the way we approach temperature-controlled environments.

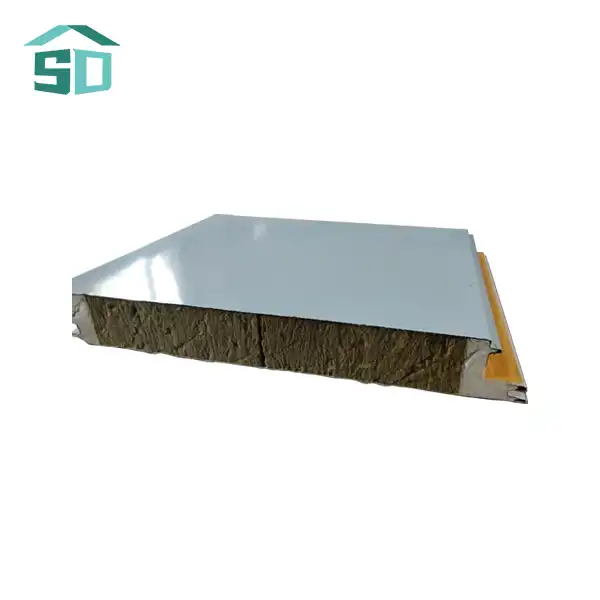

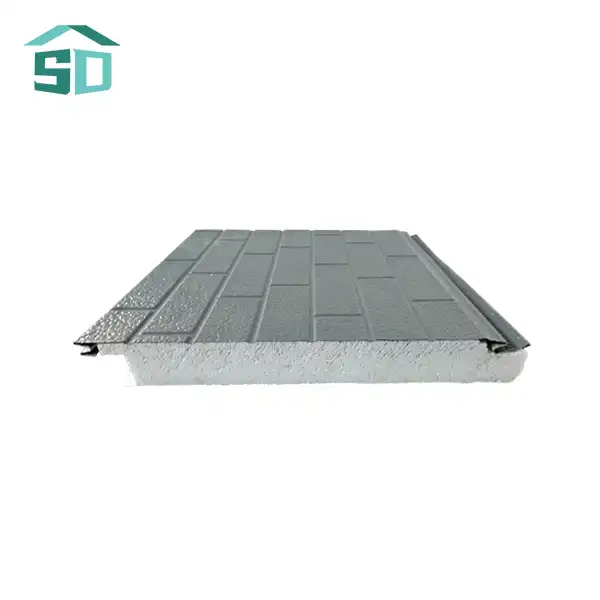

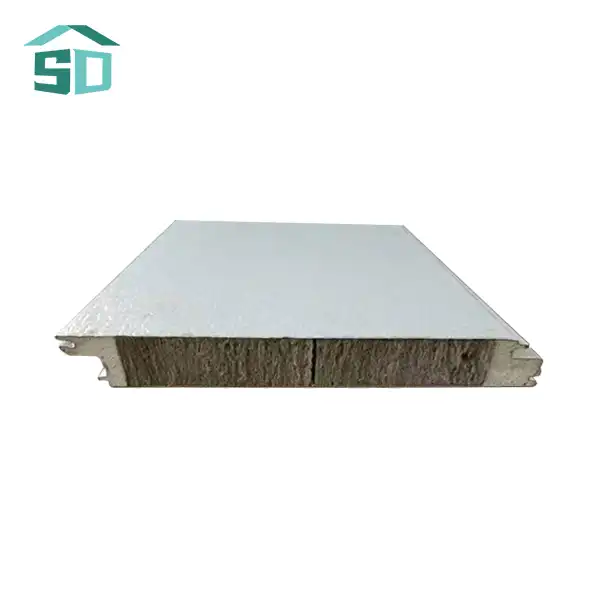

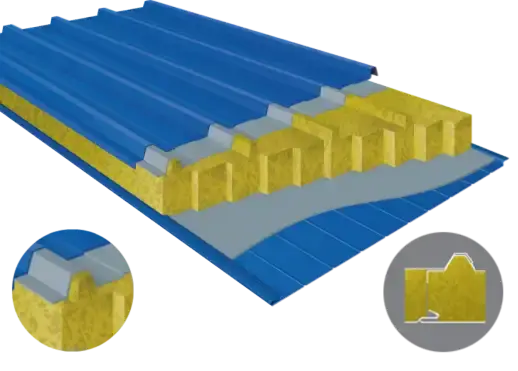

The Anatomy of Steel PU Sandwich Panels

Steel Facings: The Protective Shield

The outer layers of steel PU sandwich panels are composed of high-quality steel sheets. These facings provide exceptional strength and durability, protecting the insulating core from external damage. The steel is typically galvanized or coated with corrosion-resistant materials, ensuring longevity even in harsh environments. This robust exterior not only contributes to the panel's structural integrity but also offers a sleek, modern aesthetic that can enhance the overall appearance of cold storage facilities.

Polyurethane Core: The Insulation Powerhouse

At the heart of steel PU sandwich panels lies the polyurethane foam core. This high-density insulation material is the key to the panel's exceptional thermal performance. Polyurethane foam has a closed-cell structure that effectively traps air, minimizing heat transfer and maintaining stable temperatures within cold storage rooms. The thickness of the PU core can be customized to meet specific insulation requirements, with options typically ranging from 50mm to 100mm. This adaptability allows for tailored solutions that optimize energy efficiency in various cold storage applications.

Interlocking System: Seamless Integration

Steel PU sandwich panels are designed with an interlocking system that facilitates easy installation and creates a tight seal between panels. This tongue-and-groove configuration ensures a seamless connection, minimizing thermal bridges and preventing air infiltration. The interlocking system not only enhances the overall insulation performance but also contributes to the structural stability of the cold storage room. By creating a uniform and airtight envelope, the panels work together to maintain consistent temperatures and reduce energy consumption.

Benefits of Steel PU Sandwich Panels in Cold Storage

Superior Thermal Insulation

The primary advantage of using steel PU sandwich panels in cold storage rooms is their exceptional thermal insulation properties. The polyurethane core boasts a low thermal conductivity, which translates to minimal heat transfer between the interior and exterior environments. This high-performance insulation helps maintain precise temperature control within cold storage facilities, crucial for preserving perishable goods and sensitive materials. By effectively reducing heat gain, steel PU sandwich panels contribute to significant energy savings and lower operational costs for cold storage operators.

Moisture Resistance and Hygiene

Steel PU sandwich panels offer excellent moisture resistance, a critical feature for cold storage applications. The steel facings and sealed joints prevent water vapor infiltration, reducing the risk of condensation and mold growth within the insulation core. This moisture barrier not only preserves the panel's insulation properties but also maintains a hygienic environment essential for food storage and pharmaceutical applications. The smooth, non-porous surface of the steel facings is easy to clean and sanitize, further enhancing the overall hygiene of the cold storage facility.

Structural Strength and Durability

The combination of steel facings and a dense polyurethane core results in panels with exceptional structural strength. Steel PU sandwich panels can withstand significant loads, making them suitable for both wall and ceiling applications in cold storage rooms. This structural integrity ensures long-term stability and reduces the need for additional support structures. The durability of these panels translates to lower maintenance costs and an extended lifespan for the cold storage facility, providing a cost-effective solution for businesses in the long run.

Installation and Maintenance of Steel PU Sandwich Panels

Efficient Installation Process

One of the key advantages of steel PU sandwich panels is their ease of installation. The lightweight nature of the panels, combined with their interlocking design, allows for rapid assembly and reduced construction time. This efficiency not only lowers labor costs but also minimizes disruption to business operations during installation or upgrades. The panels can be easily cut and modified on-site to accommodate various architectural features, such as doors, windows, and utility penetrations, ensuring a custom fit for each cold storage room.

Minimal Maintenance Requirements

Steel PU sandwich panels are designed for longevity and require minimal maintenance over their lifespan. The corrosion-resistant steel facings and durable polyurethane core can withstand the harsh conditions often present in cold storage environments. Regular inspections and simple cleaning procedures are typically sufficient to maintain the panels' performance and appearance. In the event of damage, individual panels can be easily replaced without compromising the integrity of the entire structure, further reducing long-term maintenance costs and downtime.

Energy Efficiency Monitoring

To maximize the benefits of steel PU sandwich panels in cold storage applications, it's essential to implement ongoing energy efficiency monitoring. This process involves regularly assessing the thermal performance of the panels and identifying any potential areas of heat loss. Advanced monitoring systems can provide real-time data on temperature fluctuations and energy consumption, allowing facility managers to optimize cooling systems and further reduce operational costs. By maintaining the efficiency of the insulation system, businesses can ensure their cold storage rooms continue to operate at peak performance levels.

Conclusion

Steel PU sandwich panels have emerged as a game-changing solution for cold storage rooms, offering a perfect blend of insulation, durability, and efficiency. Their superior thermal properties, coupled with structural strength and ease of installation, make them an ideal choice for businesses seeking to optimize their temperature-controlled environments. By investing in steel PU sandwich panels, cold storage facilities can significantly reduce energy consumption, maintain precise temperature control, and ensure long-term reliability. As the demand for efficient cold storage solutions continues to grow, steel PU sandwich panels stand at the forefront of innovation in building materials technology.

Are you ready to revolutionize your cold storage facility with state-of-the-art steel PU sandwich panels? Weifang Sandong Building Materials Co., Ltd. offers customized solutions tailored to your specific needs. Our expert team is standing by to help you design and implement the perfect insulation system for your cold storage rooms. Don't let energy inefficiency cool down your profits – contact us today at info@sdqsc.com to discover how our steel PU sandwich panels can transform your operations and boost your bottom line.

FAQ

What thicknesses are available for steel PU sandwich panels?

Our steel PU sandwich panels are available in thicknesses of 50mm, 75mm, and 100mm, with custom options available to meet specific insulation requirements.

Are steel PU sandwich panels fire-resistant?

Yes, our panels have a Class A fire rating, ensuring compliance with building regulations and providing peace of mind in safety-conscious environments.

Can steel PU sandwich panels be customized in terms of color and finish?

Absolutely! We offer a wide range of color options based on the RAL color chart, allowing you to personalize the appearance of your cold storage facility.

Do you provide installation support for your steel PU sandwich panels?

Yes, we offer comprehensive technical support and installation guidance to ensure a smooth and efficient installation process for your cold storage project.

References

1. American Society of Heating, Refrigerating and Air-Conditioning Engineers. (2018). ASHRAE Handbook - Refrigeration. ASHRAE.

2. International Association for Cold Storage Construction. (2021). Cold Storage Design and Construction Guide. IACSC.

3. Polyurethane Foam Association. (2022). Technical Bulletin on Thermal Performance of Polyurethane Insulation. PFA.

4. Steel Construction Institute. (2020). Design Guide for Steel-Framed Buildings. SCI.

5. U.S. Department of Energy. (2021). Energy Efficiency in Cold Storage Facilities. Office of Energy Efficiency & Renewable Energy.