Advanced Sealing Techniques for Waterproof Exterior Wall Panels

When it comes to installing waterproof exterior wall panels, the sealing process plays a pivotal role in ensuring optimal performance. Advanced sealing techniques go beyond basic application methods to create a robust barrier against moisture infiltration. One such technique involves the use of high-performance sealants specifically designed for exterior applications. These sealants are engineered to withstand extreme weather conditions and maintain their flexibility over time, preventing cracks and gaps that could compromise the waterproofing integrity.

Another crucial aspect of advanced sealing is the implementation of a two-stage sealing system. This method involves applying a primary seal along the panel joints, followed by a secondary seal that acts as an additional safeguard. The primary seal typically consists of a high-grade silicone or polyurethane sealant, while the secondary seal may utilize a specialized tape or membrane. This dual-layer approach significantly reduces the risk of water penetration, even in areas subjected to heavy rainfall or strong winds.

Innovative Joint Sealing for Waterproof Exterior Wall Panels

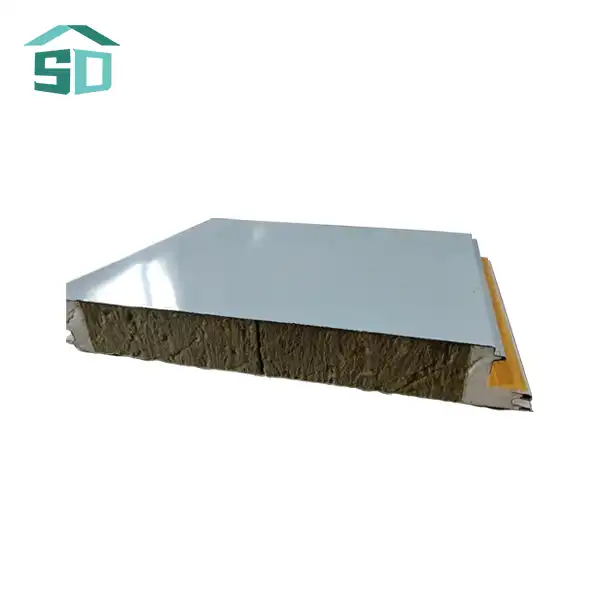

Innovative joint sealing techniques have revolutionized the installation of waterproof exterior wall panels. One such method is the use of expandable foam gaskets between panel joints. These gaskets not only provide an excellent seal but also accommodate thermal expansion and contraction, preventing stress on the panels that could lead to cracks or separation. Additionally, some waterproof exterior wall panel systems now incorporate built-in tongue-and-groove designs that create a natural seal when panels are interlocked, further enhancing their waterproofing capabilities.

For areas requiring extra protection, such as corners and transitions between different materials, installers often employ specialized corner pieces and transition profiles. These components are designed to seamlessly integrate with the waterproof exterior wall panels, creating a continuous barrier that leaves no weak points for water ingress. By paying close attention to these critical junctions, the overall waterproofing performance of the entire facade system is significantly improved.

Flashing Systems: Key to Effective Waterproofing

Flashing systems are indispensable components in the installation of waterproof exterior wall panels. They serve as the first line of defense against water infiltration at vulnerable points such as windows, doors, and other penetrations in the building envelope. A well-designed flashing system directs water away from these openings and ensures that any moisture that does penetrate is safely channeled out of the wall assembly.

Modern flashing systems for waterproof exterior wall panels often incorporate self-adhering membranes that create a seamless barrier around openings. These membranes are typically composed of rubberized asphalt or butyl rubber, offering superior adhesion and flexibility. When properly installed, they form a watertight seal that integrates seamlessly with the panel system, preventing water from seeping behind the panels and causing damage to the underlying structure.

Advanced Flashing Techniques for Waterproof Exterior Wall Panels

Advanced flashing techniques have evolved to address the unique challenges posed by various architectural designs and panel configurations. One such technique is the use of three-dimensional flashing components that are custom-fabricated to fit complex geometries. These pre-formed flashing pieces ensure a perfect fit around irregular shapes and intricate details, eliminating the risk of improper installation that could compromise waterproofing performance.

Another innovative approach in flashing systems for waterproof exterior wall panels is the integration of drainage planes. These systems incorporate channels or cavities behind the panels that allow any water that does penetrate to drain safely away from the building. By providing a clear path for water to exit, these drainage planes add an extra layer of protection, further enhancing the overall waterproofing effectiveness of the exterior wall system.

Moisture Barrier Continuity and Panel Overlap

Ensuring the continuity of the moisture barrier is paramount when installing waterproof exterior wall panels. A seamless moisture barrier prevents water from infiltrating the building envelope, protecting the underlying structure from potential damage. This continuity is achieved through meticulous attention to detail during the installation process, particularly at panel joints and transitions between different building components.

Proper panel overlap is a critical aspect of maintaining moisture barrier continuity. The overlap between panels should be designed to create a shingle effect, allowing water to flow down and away from the building surface. The specific overlap requirements may vary depending on the panel design and manufacturer recommendations, but generally, a minimum overlap of 2-3 inches is considered standard for most waterproof exterior wall panel systems.

Innovative Overlap Solutions for Waterproof Exterior Wall Panels

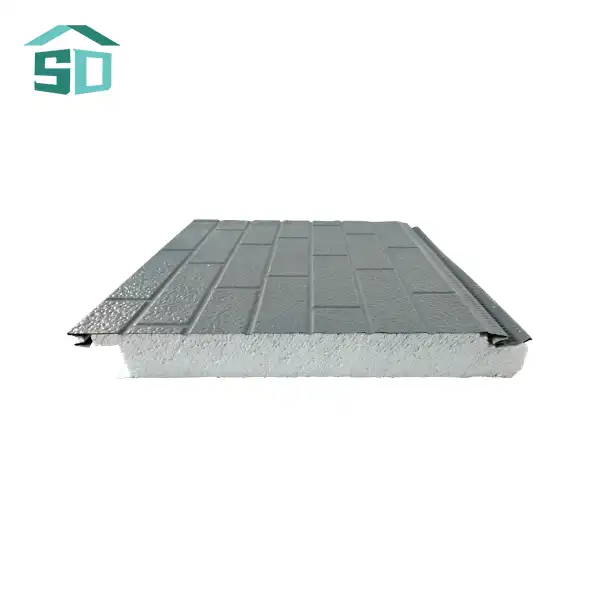

Innovative overlap solutions have been developed to enhance the performance of waterproof exterior wall panels. Some advanced panel systems now feature interlocking edges that create a tight, water-resistant seal when panels are joined together. These interlocking mechanisms not only improve waterproofing but also simplify the installation process, reducing the likelihood of errors that could compromise the system's integrity.

Additionally, some waterproof exterior wall panel manufacturers have introduced concealed fastening systems that eliminate the need for exposed screws or nails. These hidden fasteners not only improve the aesthetic appeal of the facade but also reduce potential entry points for water. By minimizing penetrations through the panel surface, these systems contribute to a more robust and reliable waterproofing solution.

Conclusion

Implementing advanced installation methods is crucial for maximizing the waterproofing performance of exterior wall panels. From innovative sealing techniques and sophisticated flashing systems to ensuring proper panel overlap and moisture barrier continuity, each aspect plays a vital role in creating a robust defense against water infiltration. By adhering to these best practices, builders and property owners can significantly enhance the longevity and effectiveness of their waterproof exterior wall panel systems. Partnering with a reliable waterproof exterior wall panels factory ensures access to high-quality materials that protect investments for years to come.

At Weifang Sandong Building Materials Co., Ltd., we understand the importance of proper installation in achieving optimal waterproofing performance. Our waterproof exterior wall panels are designed with cutting-edge technology to facilitate easy and effective installation. Whether you're planning a new construction project or renovating an existing structure, our expert team can provide guidance on the best installation methods for your specific needs. For more information on our products and services, please contact us at info@sdqsc.com.

FAQs

How often should waterproof exterior wall panels be inspected?

Regular inspections are recommended at least once a year, with additional checks after severe weather events.

Can waterproof exterior wall panels be installed over existing siding?

In many cases, yes, but it's essential to ensure the existing surface is in good condition and properly prepared.

What is the average lifespan of waterproof exterior wall panels?

With proper installation and maintenance, high-quality panels can last 30 years or more.

Are waterproof exterior wall panels suitable for all climates?

Yes, but it's important to choose panels specifically designed for your local climate conditions.

How do waterproof exterior wall panels contribute to energy efficiency?

Many panels include insulation properties that can help reduce heat transfer, improving overall building energy efficiency.

References

1. Building Science Corporation. (2020). "Water Management and Exterior Wall Systems."

2. National Institute of Building Sciences. (2021). "Whole Building Design Guide: Building Envelope Design Guide."

3. American Society for Testing and Materials. (2019). "ASTM E2112-19: Standard Practice for Installation of Exterior Windows, Doors and Skylights." ASTM International.

4. International Code Council. (2021). "International Building Code." ICC.

5. U.S. Department of Energy. (2020). "Building America Solution Center: Wall Assemblies."