Comprehending Passive House Design and Its Requirements

Passive house design is an architectural concept that aims to create ultra-low energy buildings that require minimal heating or cooling. This approach relies heavily on superinsulation, airtightness, and strategic use of solar energy to maintain comfortable indoor temperatures year-round. To meet passive house standards, buildings must adhere to strict criteria for energy consumption, airtightness, and thermal comfort.

The Importance of Insulation in Passive House Design

Insulation is the cornerstone of passive house design, acting as a critical thermal barrier that prevents unwanted heat transfer between a building’s interior and exterior. By minimizing energy loss, effective insulation reduces the demand for heating and cooling systems, contributing to a more stable and comfortable indoor climate while lowering energy costs. In this context, aluminum foam sandwich panels have emerged as an innovative and highly effective solution, offering a combination of lightweight construction, structural strength, and superior thermal performance for energy-efficient buildings.

The Role of Aluminum Foam Sandwich Panels

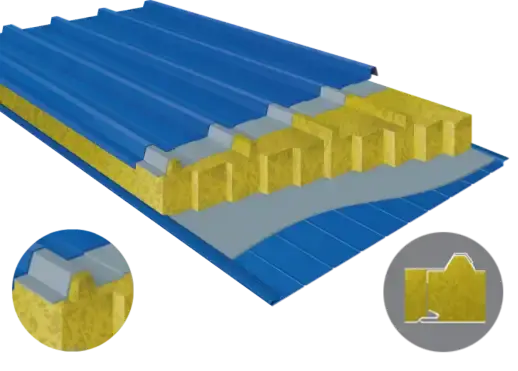

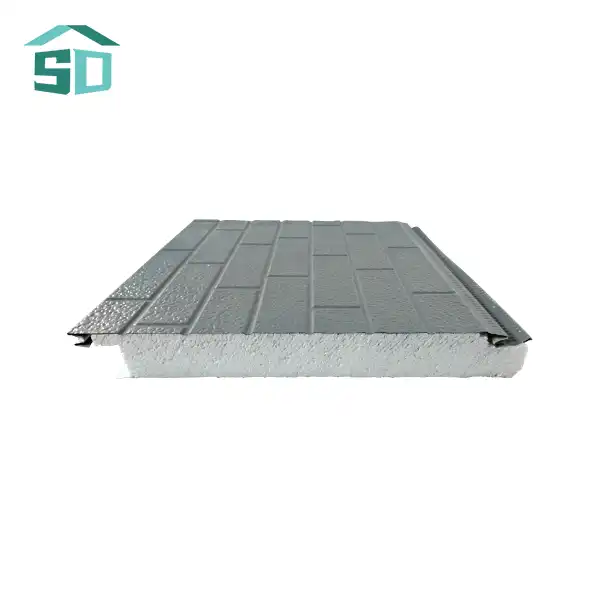

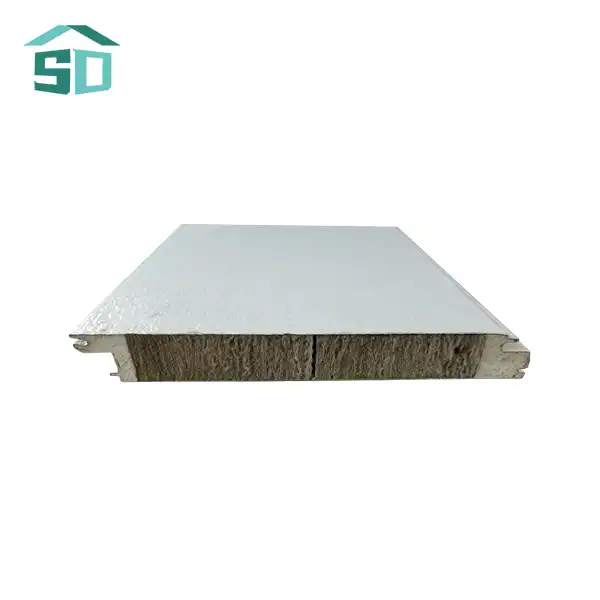

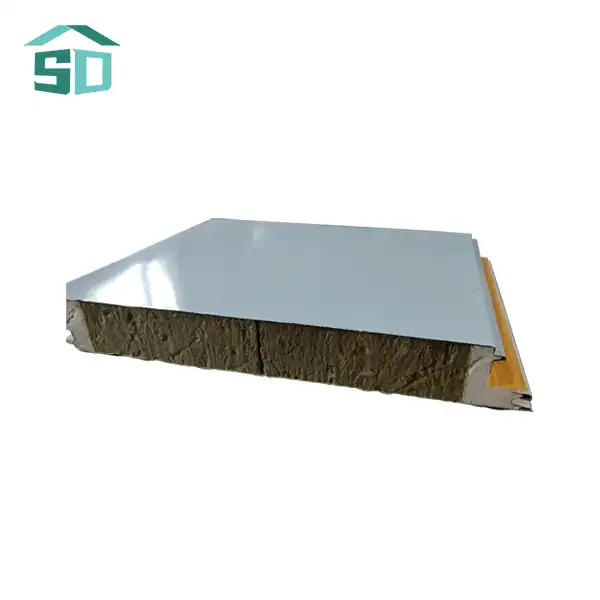

Aluminum foam sandwich panels are advanced composite materials composed of two dense aluminum face sheets that encase a lightweight aluminum foam core. This innovative structure merges the strength, durability, and corrosion resistance of aluminum with the excellent thermal and acoustic insulating properties of foam. The factory-controlled production process ensures uniform quality, precise dimensions, and reliable performance across all panels. These attributes make aluminum foam sandwich panels an ideal choice for passive house construction, where energy efficiency, structural integrity, and long-term sustainability are paramount.

Benefits of Aluminum Foam Sandwich Panels in Passive House Design

The integration of aluminum foam sandwich panels in passive house design offers numerous advantages that contribute to the overall performance and sustainability of the building.

Superior Thermal Insulation

Aluminum foam sandwich panels boast remarkable thermal insulation properties. The porous structure of the aluminum foam core creates countless tiny air pockets, effectively reducing heat conduction. This characteristic makes aluminum foam sandwich panels exceptionally efficient in maintaining the desired indoor temperature, a crucial aspect of passive house design.

Structural Integrity and Lightweight Design

Despite their lightweight nature, aluminum foam sandwich panels provide remarkable structural strength and rigidity. The combination of low weight and high load-bearing capacity makes these panels suitable for a wide range of applications in passive house construction, including walls, roofs, and even floors. Their reduced mass simplifies transportation, handling, and installation on-site, reducing labor demands and construction time. Additionally, the lighter panels place less stress on the overall building structure, potentially allowing for cost savings in foundation design and supporting frameworks, while maintaining long-term durability and performance.

Enhanced Energy Efficiency

The use of aluminum foam sandwich panels in passive houses can lead to significant gains in energy efficiency. The foam core provides exceptional thermal insulation, effectively minimizing heat transfer through walls, roofs, and floors. This results in substantially lower heating and cooling requirements, helping to maintain a stable indoor climate year-round. By reducing reliance on active HVAC systems, these panels contribute to energy conservation and lower utility costs. Their integration into passive house designs aligns perfectly with the goal of achieving minimal energy consumption while maximizing occupant comfort and sustainability.

Applications of Aluminum Foam Sandwich Panels in Passive House Construction

The versatility of aluminum foam sandwich panels allows for their integration into various aspects of passive house construction.

Wall and Roof Insulation

Aluminum foam sandwich panels excel as insulation materials for walls and roofs in passive houses. Their high thermal resistance and ability to create a continuous insulation layer help eliminate thermal bridges, a common source of heat loss in buildings. The aluminum foam sandwich panels factory can produce custom-sized panels to fit specific architectural requirements, ensuring optimal coverage and performance.

Floor Insulation

In passive house design, effective floor insulation is essential to prevent heat loss through the ground and maintain a comfortable indoor environment. Aluminum foam sandwich panels provide an excellent solution for floor applications, combining superior thermal insulation with reliable structural integrity. These panels can be seamlessly integrated into the floor assembly, ensuring uniform thermal performance across the building’s base. Their lightweight nature simplifies installation, while their durability supports long-term use. By enhancing the floor’s insulating capabilities, aluminum foam sandwich panels contribute significantly to the overall efficiency and energy performance of a passive house.

Window and Door Frames

Windows and doors are common weak points in a building’s thermal envelope, often allowing unwanted heat transfer and drafts. Incorporating aluminum foam sandwich panels into window and door frames can greatly improve their insulating performance. The panels’ low thermal conductivity helps maintain consistent indoor temperatures, reducing energy consumption for heating and cooling. Additionally, their moisture-resistant properties prevent condensation and potential mold growth around openings. By enhancing the thermal efficiency of windows and doors, aluminum foam sandwich panels play a vital role in achieving the energy-saving and comfort goals central to passive house design.

Conclusion

Aluminum foam sandwich panels play a pivotal role in achieving the high performance standards required for passive house design. Their superior thermal insulation, structural integrity, and versatility make them an invaluable asset in creating energy-efficient, comfortable, and sustainable buildings. As the demand for environmentally conscious construction continues to grow, the importance of innovative materials like aluminum foam sandwich panels will only increase.

At Weifang Sandong Building Materials Co., Ltd., we are committed to providing high-quality aluminum foam sandwich panels and other exterior cladding solutions to meet the evolving needs of sustainable architecture. Our advanced production lines and rigorous quality control ensure that our products meet the stringent requirements of passive house design. Whether you're planning a new construction project or renovating an existing structure, our expert team is ready to assist you in selecting the perfect insulation solutions. Contact us at info@sdqsc.com to learn more about how our aluminum foam sandwich panels can enhance your passive house project.

FAQ

What makes aluminum foam sandwich panels suitable for passive house design?

Aluminum foam sandwich panels offer superior thermal insulation, structural strength, and lightweight design, making them ideal for meeting passive house standards.

Can aluminum foam sandwich panels be used in both new construction and renovation projects?

Yes, these versatile panels are suitable for both new builds and retrofitting existing structures to improve energy efficiency.

How do aluminum foam sandwich panels compare to traditional insulation materials?

Aluminum foam sandwich panels generally outperform traditional materials in terms of thermal insulation, strength-to-weight ratio, and durability.

References

1.Passive House Institute. (2021). Passive House Requirements.

2.Banhart, J. (2001). Manufacture, characterisation and application of cellular metals and metal foams. Progress in Materials Science, 46(6), 559-632.

3.Ashby, M. F., Evans, A. G., Fleck, N. A., Gibson, L. J., Hutchinson, J. W., & Wadley, H. N. G. (2000). Metal Foams: A Design Guide. Butterworth-Heinemann.

4.International Passive House Association. (2022). Active for More Comfort: Passive House.