Comprehending the Composition and Benefits of Metal Sheet PU Sandwich Panels

The Anatomy of a Metal Sheet PU Sandwich Panel

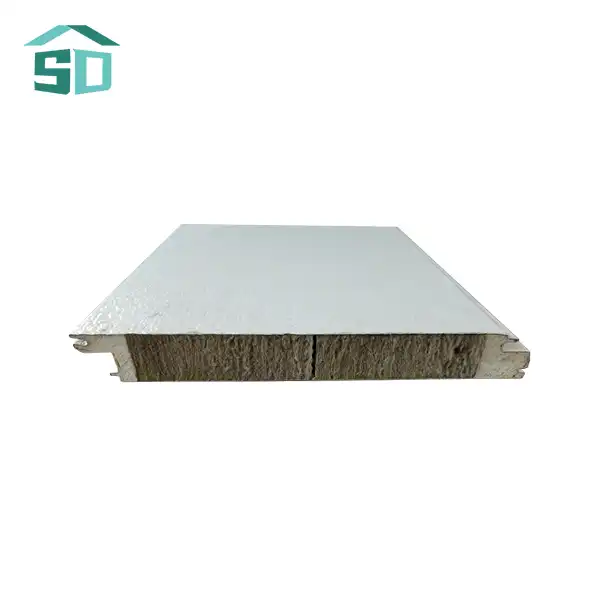

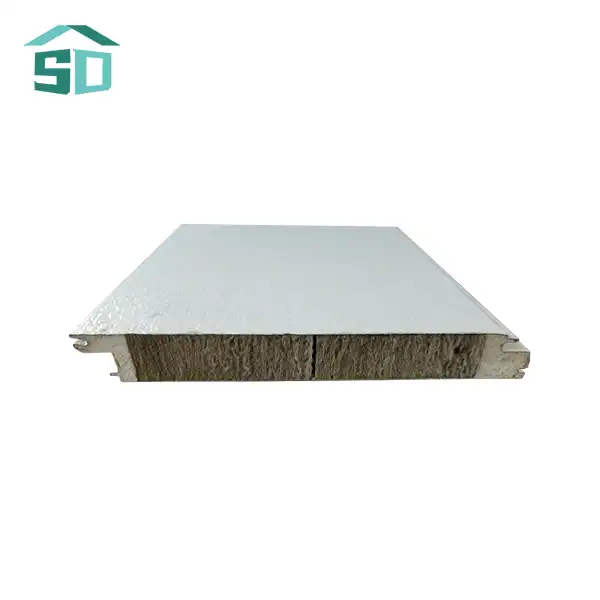

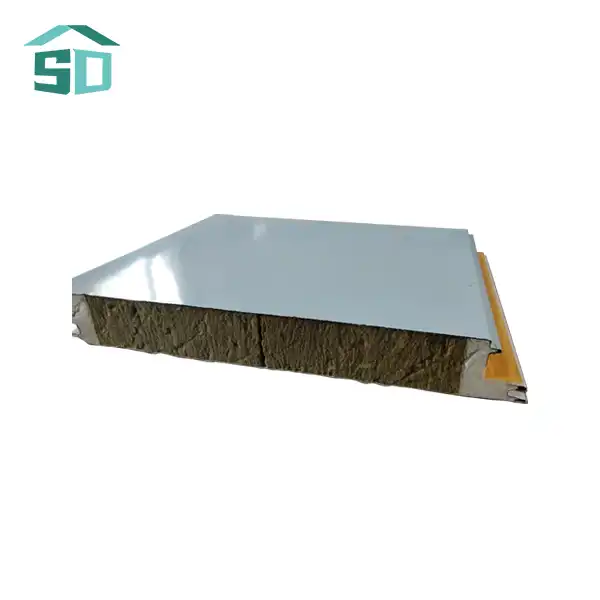

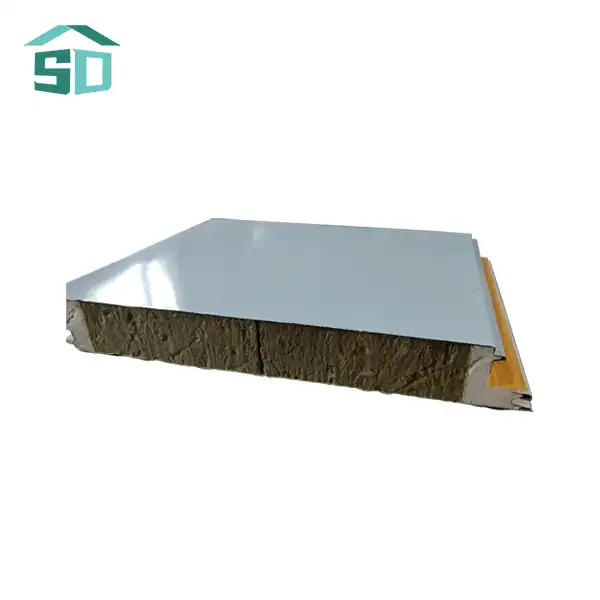

At its core, a metal sheet PU sandwich panel consists of three main components. The outer layers are typically made of high-quality metal sheets, such as steel or aluminum, while the inner core is composed of rigid polyurethane foam. This unique structure is what gives the panel its exceptional properties. The metal sheets provide durability and weather resistance, while the PU foam core offers superior insulation and lightweight characteristics. Together, these elements create a building material that's both strong and energy-efficient.

Key Advantages of Metal Sheet PU Sandwich Panels

Key Advantages of Metal Sheet PU Sandwich Panels

The benefits of using metal sheet PU sandwich panels in construction are numerous. First and foremost is their excellent thermal insulation properties. The polyurethane core acts as a highly effective barrier against heat transfer, helping to maintain comfortable indoor temperatures while reducing energy costs. Additionally, these panels boast impressive strength-to-weight ratios, making them ideal for a wide range of applications without putting undue stress on building structures. Their durability is another key selling point, with resistance to corrosion, moisture, and UV radiation ensuring longevity in various environmental conditions.

Versatility in Design and Application

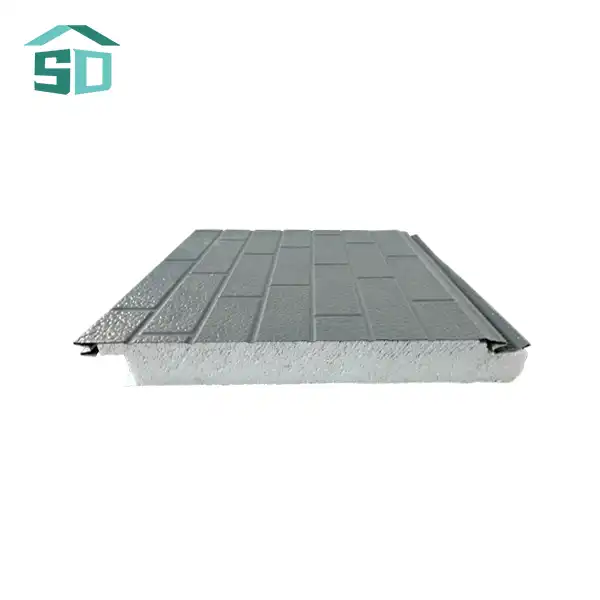

One of the most appealing aspects of metal sheet PU sandwich panels is their versatility. They can be customized in terms of thickness, color, and surface finish to suit specific project requirements. This flexibility allows architects and designers to achieve their desired aesthetic while still benefiting from the panel's functional properties. From residential buildings to commercial complexes, these panels find applications in walls, roofs, and even cold storage facilities. Their ease of installation also contributes to faster construction times and reduced labor costs, making them an attractive option for both new builds and renovation projects.

Cost-Effectiveness and Long-Term Value of PU Sandwich Panels

Initial Investment vs. Long-Term Savings

When considering the use of metal sheet PU sandwich panels, it's important to look beyond the initial cost. While the upfront investment may be higher compared to some traditional building materials, the long-term benefits often outweigh this initial expense. The superior insulation properties of these panels can lead to significant energy savings over time, reducing heating and cooling costs for the building's entire lifespan. Moreover, their durability means less frequent replacements and repairs, further contributing to cost savings in the long run.

Reduced Construction Time and Labor Costs

Another factor contributing to the cost-effectiveness of metal sheet PU sandwich panels is their ease of installation. These lightweight panels can be quickly and easily assembled, significantly reducing construction time compared to traditional building methods. This not only translates to lower labor costs but also allows for faster project completion, which can be particularly advantageous in commercial construction where time is often of the essence. The simplified installation process also minimizes the risk of errors, potentially reducing future maintenance and repair costs.

Environmental Impact and Sustainability

In an era where sustainability is increasingly important, the environmental benefits of metal sheet PU sandwich panels should not be overlooked. Their energy-efficient properties contribute to reduced carbon emissions over the building's lifetime. Additionally, many metal sheet PU sandwich manufacturers are now focusing on using recyclable materials and environmentally friendly production processes. This not only helps meet green building standards but can also lead to potential tax incentives or certifications that add value to the property.

Innovations and Future Trends in PU Sandwich Panel Technology

Advancements in Material Science

The field of metal sheet PU sandwich panel production is constantly evolving, with ongoing research and development aimed at enhancing their properties. Recent advancements include improvements in fire resistance, acoustic insulation, and structural integrity. Some metal sheet PU sandwich manufacturers are exploring the use of bio-based polyurethane foams, which offer similar performance characteristics while reducing the environmental impact. These innovations are expanding the potential applications of PU sandwich panels and making them an even more attractive option for sustainable construction.

Integration with Smart Building Technologies

As the construction industry moves towards smarter, more connected buildings, metal sheet PU sandwich panels are not being left behind. Manufacturers are exploring ways to integrate sensors and other smart technologies directly into the panels. This could allow for real-time monitoring of a building's thermal performance, structural integrity, and even air quality. Such advancements could revolutionize building maintenance and energy management, further enhancing the long-term value proposition of PU sandwich panels.

Customization and Aesthetic Innovations

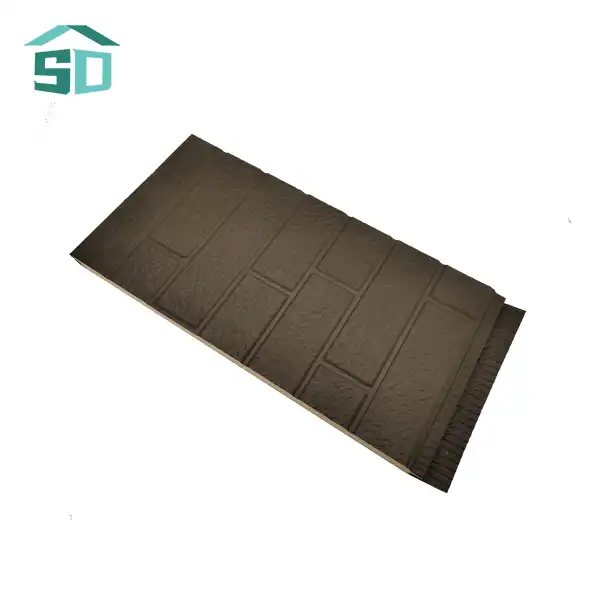

While the functional benefits of metal sheet PU sandwich panels are well-established, there's also a growing focus on their aesthetic potential. Manufacturers are developing new finishes and textures that can mimic the appearance of traditional building materials like wood or stone, while still retaining the panels' core benefits. This allows architects and designers even greater flexibility in creating visually appealing structures without compromising on performance. As these aesthetic options continue to expand, we can expect to see PU sandwich panels used in an even wider variety of architectural styles and applications.

Conclusion

Metal sheet PU sandwich panels represent a significant leap forward in building technology, offering a unique balance of strength, efficiency, and cost-effectiveness. Their versatility, combined with ongoing innovations in the field, positions them as a key player in the future of sustainable construction. As we continue to seek out materials that can meet the demanding requirements of modern building practices, PU sandwich panels stand out as a solution that can truly deliver on multiple fronts.

At Weifang Sandong Building Materials Co., Ltd., we're committed to providing top-quality metal sheet PU sandwich panels that meet the evolving needs of the construction industry. Our advanced production lines and rigorous quality control ensure that each panel meets the highest standards of performance and durability. Whether you're planning a new construction project or looking to upgrade existing structures, our team is here to help you find the perfect PU sandwich panel solution. To learn more about our products and how they can benefit your next project, don't hesitate to reach out to us at info@sdqsc.com.

FAQ

What are the main advantages of using metal sheet PU sandwich panels?

Metal sheet PU sandwich panels offer excellent thermal insulation, high strength-to-weight ratio, durability, and versatility in design and application.

Are metal sheet PU sandwich panels environmentally friendly?

Yes, they contribute to energy efficiency and reduced carbon emissions. Many manufacturers also use recyclable materials and eco-friendly production processes.

Can metal sheet PU sandwich panels be customized?

Absolutely. These panels can be customized in terms of thickness, color, surface finish, and even integrated with smart technologies to suit specific project requirements.

References

1.Building and Environment Journal. "Thermal Performance of Polyurethane Sandwich Panels in Building Envelopes." 2021.

2.Journal of Building Engineering. "Advancements in Metal-Faced Sandwich Panel Technology for Building Construction." 2022.

3.Sustainability in Construction. "Life Cycle Assessment of PU Sandwich Panels in Modern Architecture." 2023.

4.Energy and Buildings. "Comparative Study of Insulation Materials in Construction: Focus on PU Sandwich Panels." 2022.