Understanding Aluminum Foam Sandwich Panels

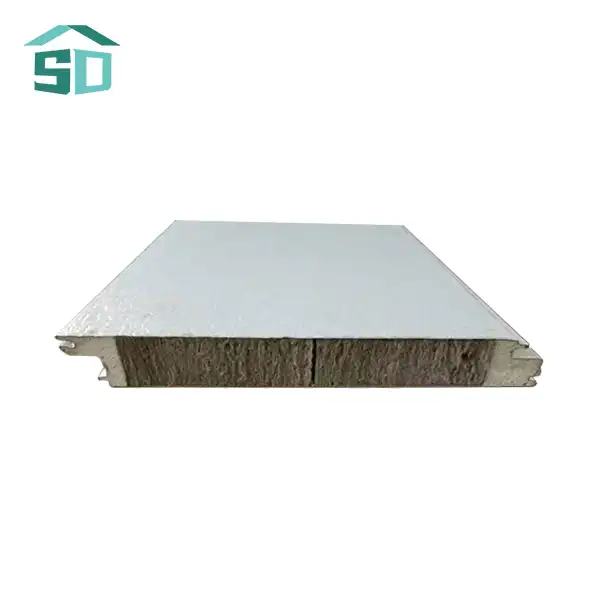

Aluminum foam sandwich panels, also known as AFS panels, represent a cutting-edge composite material that combines the strength of aluminum with the lightweight properties of foam. These panels consist of two thin, dense aluminum face sheets bonded to a core of aluminum foam, creating a structure that's both robust and incredibly light.

The Composition of Aluminum Foam Sandwich Panels

The unique structure of aluminum foam sandwich panels is what sets them apart from traditional building materials. The core is made of aluminum foam, a cellular structure of aluminum with a high porosity. This foam core is sandwiched between two solid aluminum sheets, creating a panel that offers exceptional strength-to-weight ratio.

The manufacturing process of aluminum foam sandwich panels involves several steps:

1. Creation of aluminum foam through various methods such as gas injection or powder metallurgy

2. Bonding of the foam core to the aluminum face sheets

3. Precision cutting and shaping to meet specific project requirements

This meticulous process ensures that each aluminum foam sandwich panel meets the highest standards of quality and performance.

Key Properties of Aluminum Foam Sandwich Panels

Aluminum foam sandwich panels boast a unique set of properties that make them invaluable in architectural applications:

- Lightweight: Despite their robust nature, these panels are significantly lighter than solid aluminum sheets of comparable thickness.

- High Strength-to-Weight Ratio: The combination of aluminum face sheets and foam core results in exceptional structural integrity without excessive weight.

- Thermal Insulation: The foam core provides excellent thermal insulation, contributing to energy efficiency in buildings.

- Sound Dampening: The cellular structure of the foam core helps absorb sound, making these panels ideal for noise reduction applications.

- Fire Resistance: Aluminum foam sandwich panels can be engineered to meet stringent fire safety standards.

- Recyclability: Being primarily composed of aluminum, these panels are highly recyclable, aligning with sustainable building practices.

These properties make aluminum foam sandwich panels a versatile solution for various architectural challenges, from energy-efficient building envelopes to lightweight structural elements.

Applications in Modern Architecture

The unique properties of aluminum foam sandwich panels have led to their adoption in diverse architectural applications. Let's explore some of the key areas where these innovative panels are making a significant impact.

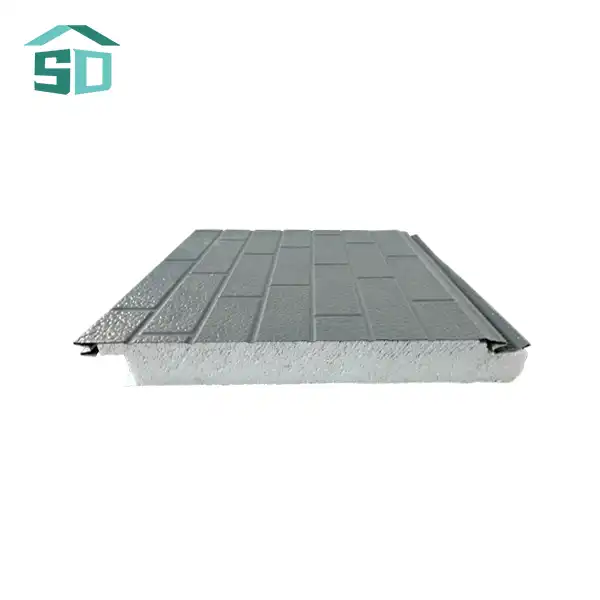

Facades and Cladding

One of the most prominent uses of aluminum foam sandwich panels is in building facades and cladding. Architects and designers are increasingly turning to these panels for their ability to create striking visual effects while maintaining structural integrity. The lightweight nature of aluminum foam sandwich panels allows for the creation of large, seamless surfaces that can dramatically alter a building's appearance.

Moreover, the thermal insulation properties of these panels contribute to improved energy efficiency in buildings. By reducing heat transfer between the interior and exterior, aluminum foam sandwich panels help maintain comfortable indoor temperatures while reducing heating and cooling costs.

Structural Elements

Beyond aesthetics, aluminum foam sandwich panels are finding applications in structural elements of buildings. Their high strength-to-weight ratio makes them ideal for load-bearing components, particularly in situations where weight reduction is crucial. This property has led to their use in:

- Roof structures

- Floor systems

- Bridge decks

- Partition walls

In these applications, aluminum foam sandwich panels offer the dual benefits of structural support and weight reduction, potentially leading to more efficient building designs and reduced foundation requirements.

Interior Design and Acoustics

The versatility of aluminum foam sandwich panels extends to interior applications as well. Their sound-dampening properties make them an excellent choice for creating quiet, comfortable indoor environments. Architects and interior designers are utilizing these panels in:

- Acoustic wall panels

- Ceiling systems

- Room dividers

- Exhibition displays

The ability to customize the surface finish of aluminum foam sandwich panels allows for a wide range of aesthetic options, from sleek, modern looks to more textured, industrial designs.

The Future of Aluminum Foam Sandwich Panels in Architecture

As the construction industry continues to evolve, the role of aluminum foam sandwich panels is expected to grow. Several factors are driving this trend:

Advancements in Manufacturing Technology

Ongoing improvements in the production of aluminum foam sandwich panels are leading to enhanced performance and wider applications. Innovations in foam creation techniques and bonding processes are resulting in panels with even better strength-to-weight ratios and improved durability.

Furthermore, advancements in aluminum foam sandwich panels factory operations are enabling more efficient production, potentially reducing costs and making these panels more accessible to a broader range of projects. As manufacturing techniques continue to refine, we can expect to see aluminum foam sandwich panels with even more impressive properties and versatility.

Sustainable Building Practices

The push towards sustainable architecture is another factor driving the adoption of aluminum foam sandwich panels. Their recyclability and contribution to energy efficiency align well with green building standards. As architects and builders increasingly prioritize environmentally friendly materials, aluminum foam sandwich panels are poised to play a significant role in sustainable design strategies.

Moreover, the longevity of these panels can contribute to reduced maintenance and replacement cycles, further enhancing their sustainability credentials. The durability of aluminum foam sandwich panels means they can withstand harsh environmental conditions, potentially outlasting traditional building materials in many applications.

Innovative Design Possibilities

The unique properties of aluminum foam sandwich panels are inspiring architects to push the boundaries of design. The ability to create large, lightweight structures is opening up new possibilities in architectural forms. From sweeping curves to complex geometries, these panels are enabling designs that were previously challenging or impossible to achieve with conventional materials.

Additionally, the customization options available with aluminum foam sandwich panels allow for creative expression in building facades. Whether it's through color, texture, or perforation patterns, these panels offer architects a canvas for innovative aesthetic treatments.

Conclusion

The rise of aluminum foam sandwich panels in architecture marks a significant shift in building technology and design possibilities. These innovative materials offer a unique combination of strength, lightness, and versatility that is reshaping our built environment. From energy-efficient facades to structural components and interior design elements, aluminum foam sandwich panels are proving their value across a wide spectrum of architectural applications.

As we look to the future, the continued development and adoption of these panels promise to drive further innovations in sustainable, efficient, and aesthetically pleasing architecture. The journey of aluminum foam sandwich panels is just beginning, and their potential to transform our buildings and cities is truly exciting.

At Weifang Sandong Building Materials Co., Ltd., we're at the forefront of this architectural revolution. Our state-of-the-art production lines and rigorous quality control ensure that our aluminum foam sandwich panels meet the highest standards of performance and durability. Whether you're planning a new construction project or a renovation, our panels offer the perfect blend of aesthetics, durability, and efficiency. Ready to elevate your next architectural project? Contact us at info@sdqsc.com to explore how our aluminum foam sandwich panels can bring your vision to life.

FAQ

What are the main advantages of using aluminum foam sandwich panels in construction?

Aluminum foam sandwich panels offer numerous benefits, including high strength-to-weight ratio, excellent thermal insulation, sound dampening properties, fire resistance, and recyclability. They are versatile, suitable for both exterior and interior applications, and can significantly enhance energy efficiency in buildings.

How do aluminum foam sandwich panels contribute to sustainable architecture?

These panels contribute to sustainability through their recyclability, energy efficiency properties, and durability. They help reduce a building's carbon footprint by improving insulation and potentially lowering heating and cooling costs. Their long lifespan also means less frequent replacements, further supporting sustainable building practices.

References

1. Banhart, J. (2001). Manufacture, characterisation and application of cellular metals and metal foams. Progress in Materials Science, 46(6), 559-632.

2. Ashby, M. F., Evans, A. G., Fleck, N. A., Gibson, L. J., Hutchinson, J. W., & Wadley, H. N. G. (2000). Metal Foams: A Design Guide. Butterworth-Heinemann.

3. Kováčik, J., Jerz, J., Mináriková, N., Marsavina, L., & Linul, E. (2016). Scaling of compression strength in disordered solids: Metallic foams. Frattura ed Integrità Strutturale, 10(36), 55-62.

4. Crupi, V., Epasto, G., & Guglielmino, E. (2013). Comparison of aluminium sandwiches for lightweight ship structures: Honeycomb vs. foam. Marine Structures, 30, 74-96.

5. Wadley, H. N. G. (2006). Multifunctional periodic cellular metals. Philosophical Transactions of the Royal Society A: Mathematical, Physical and Engineering Sciences, 364(1838), 31-68.