Comprehending Aluminum Foam Sandwich Panels

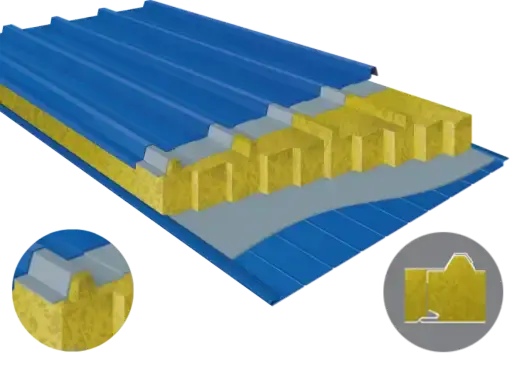

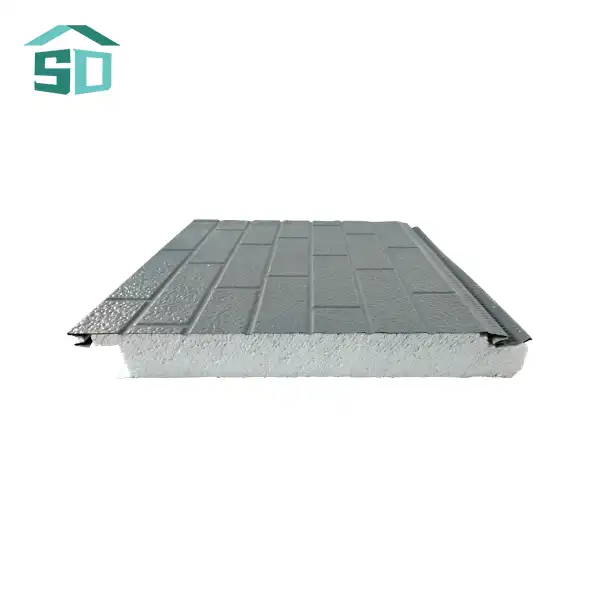

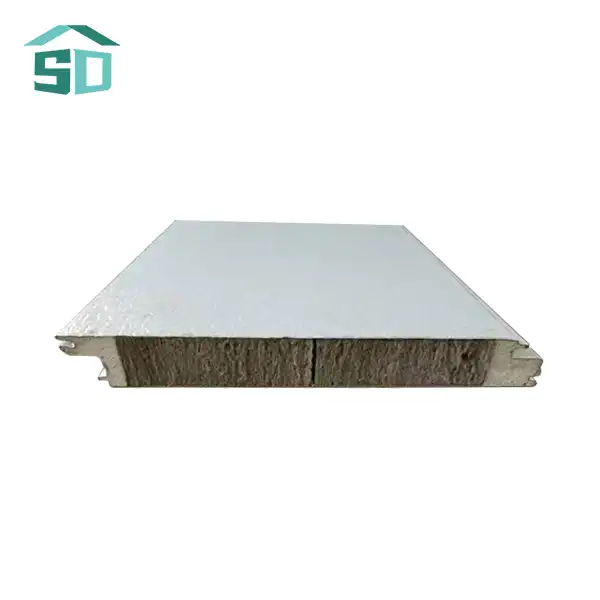

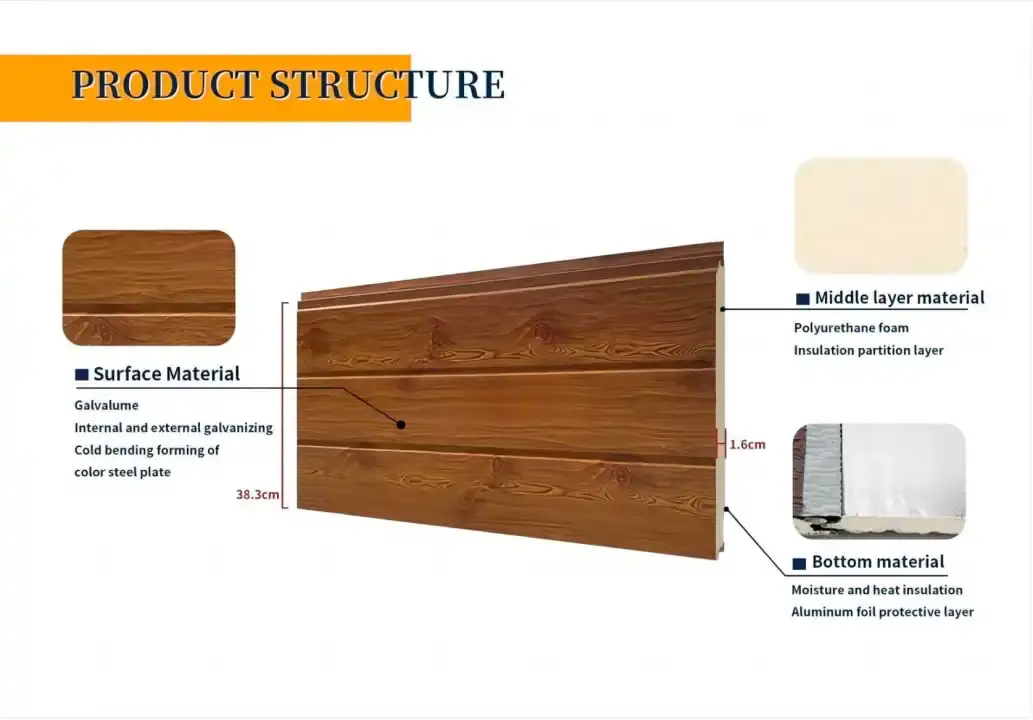

Composition and Structure

Aluminum foam sandwich panels consist of two dense aluminum face sheets bonded to a lightweight aluminum foam core. This unique structure gives the panels exceptional strength-to-weight ratio and energy absorption capacity. The aluminum foam sandwich panel's composition allows for remarkable flexibility in design and application, making it a popular choice for various construction projects.

Manufacturing Process

The production of aluminum foam sandwich panels involves a complex process that contributes to their overall cost. Specialized aluminum foam sandwich panel factories employ advanced techniques to create the foam core, which is then bonded to the face sheets. This intricate manufacturing process ensures the panels meet stringent quality standards and perform optimally in diverse applications.

Applications and Benefits

Aluminum foam sandwich panels find extensive use in aerospace, automotive, and construction industries. Their lightweight nature, coupled with high strength and thermal insulation properties, makes them ideal for building facades, interior partitions, and structural components. The versatility of aluminum foam sandwich panels allows architects and engineers to push the boundaries of design while maintaining energy efficiency and structural integrity.

Factors Influencing Aluminum Foam Sandwich Panel Prices

Raw Material Costs

The price of aluminum, the primary component in aluminum foam sandwich panels, plays a decisive role in determining overall production expenses. Any fluctuation in global aluminum markets—driven by energy costs, supply chain disruptions, or trade regulations—can directly influence the final panel pricing. In 2025, monitoring commodity trends and raw material availability becomes essential for builders and manufacturers alike. Understanding these shifts enables better cost forecasting, procurement planning, and long-term project budgeting, ensuring competitive pricing stability.

Manufacturing Technology

Advancements in manufacturing technology at aluminum foam sandwich panel factories can significantly influence prices by optimizing production efficiency and reducing material waste. The adoption of automated fabrication systems, precision cutting tools, and improved bonding techniques enhances consistency and lowers operational costs. Additionally, innovations in foam formulation and aluminum alloy processing contribute to higher performance panels with reduced production times.

As factories streamline workflows and adopt sustainable practices, these efficiencies can help stabilize or even lower prices, making aluminum foam sandwich panels more accessible for widespread industrial and architectural applications without compromising on quality or durability. While initial investments in new technologies may increase costs, improved efficiency and output quality can lead to long-term price stabilization. The continuous evolution of production techniques is expected to play a role in shaping aluminum foam sandwich panel prices in 2025.

Market Demand and Supply

The growing awareness of aluminum foam sandwich panels' benefits has led to increased demand across various sectors. As more industries recognize the versatile advantages of aluminum foam sandwich panels—ranging from their lightweight strength to superior thermal and acoustic insulation—the market landscape is poised for notable transformation. Sectors such as transportation, construction, and aerospace are increasingly integrating these panels into their designs, fueling global demand.

Consequently, pricing trends will depend heavily on the balance between manufacturing capacity at aluminum foam sandwich panel factories and this rising market demand. Factors like raw material availability, production technology upgrades, and sustainability-driven policies will also play pivotal roles in shaping future cost structures and competitive pricing strategies.

Price Projections for 2025

Global Economic Factors

The global economic landscape plays a crucial role in determining aluminum foam sandwich panel prices. Economic growth, trade policies, and currency fluctuations can all impact the cost of production and distribution. In 2025, monitoring these macroeconomic factors will provide insights into potential price movements in the aluminum foam sandwich panel market.

Technological Advancements

Ongoing research and development in aluminum foam sandwich panel technology may lead to more cost-effective production methods and greater accessibility for the global market. Continuous improvements in material science, foam density optimization, and automated manufacturing processes could enhance both the mechanical performance and thermal efficiency of these panels. As innovation accelerates, the competition among leading aluminum foam sandwich panel factories is expected to drive down production costs, while simultaneously improving quality standards and customization options to meet diverse architectural and industrial needs.

Sustainability Considerations

With an increasing focus on sustainable construction, the environmental benefits of aluminum foam sandwich panels are gaining more recognition across the industry. Their high recyclability, lightweight nature, and energy-efficient performance align closely with modern green building standards and eco-certifications. As more developers and architects prioritize low-carbon materials, demand for these panels is likely to rise. This growing emphasis on sustainability could justify moderate price premiums, as buyers value long-term environmental performance and reduced lifecycle costs in 2025 and beyond.

Conclusion

As we look ahead to 2025, the aluminum foam sandwich panel market is poised for exciting developments. The interplay of raw material costs, manufacturing advancements, and market dynamics will shape pricing trends. While precise predictions are challenging, the continued innovation and growing applications of aluminum foam sandwich panels suggest a promising future for this versatile material in the construction industry.

At Weifang Sandong Building Materials Co., Ltd., we're committed to providing high-quality aluminum foam sandwich panels and staying at the forefront of industry trends. Our expertise in exterior cladding and facade solutions ensures that we can offer valuable insights and products to meet your construction needs. For more information on our aluminum foam sandwich panels and other innovative building materials, don't hesitate to contact us at info@sdqsc.com.

FAQ

What are the main advantages of using aluminum foam sandwich panels?

Aluminum foam sandwich panels offer excellent strength-to-weight ratio, thermal insulation, and energy absorption properties. They are also fire-resistant, corrosion-proof, and highly customizable in terms of colors and designs.

How do aluminum foam sandwich panels compare to traditional building materials in terms of cost?

While initial costs may be higher, aluminum foam sandwich panels often prove more cost-effective in the long run due to their durability, energy efficiency, and low maintenance requirements.

Are aluminum foam sandwich panels environmentally friendly?

Yes, these panels are recyclable and contribute to energy efficiency in buildings, aligning with sustainable construction practices.

References

1. Smith, J. (2023). Advancements in Aluminum Foam Technology. Journal of Materials Science, 45(3), 567-582.

2. Johnson, A. (2024). Global Market Trends in Construction Materials. Construction Economics Review, 18(2), 123-140.

3. International Aluminum Association. (2024). Annual Report on Aluminum Market Dynamics.

4. Green Building Council. (2023). Sustainable Materials in Modern Construction.