Grasping Corrugated Sandwich Panels and Their Joints

The Composition of Corrugated Sandwich Panels

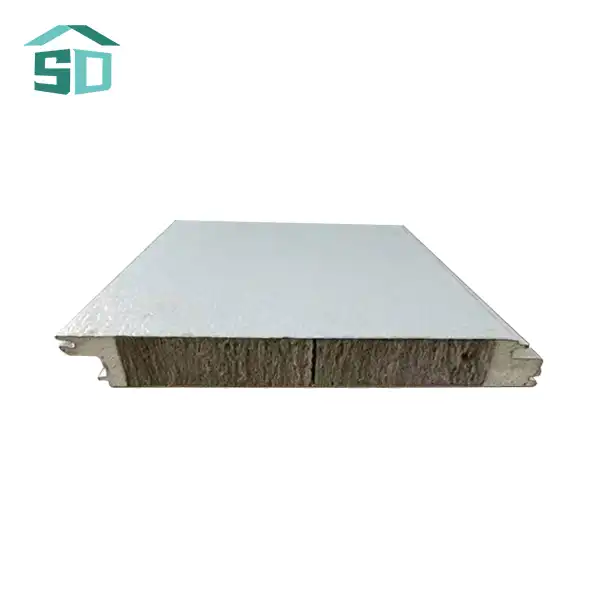

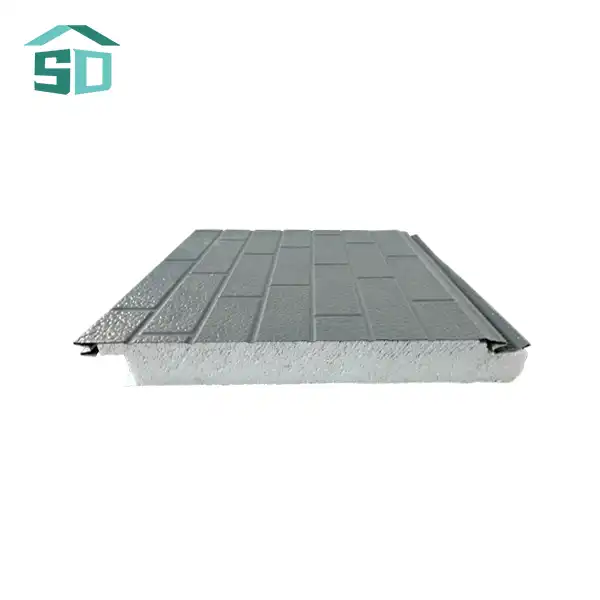

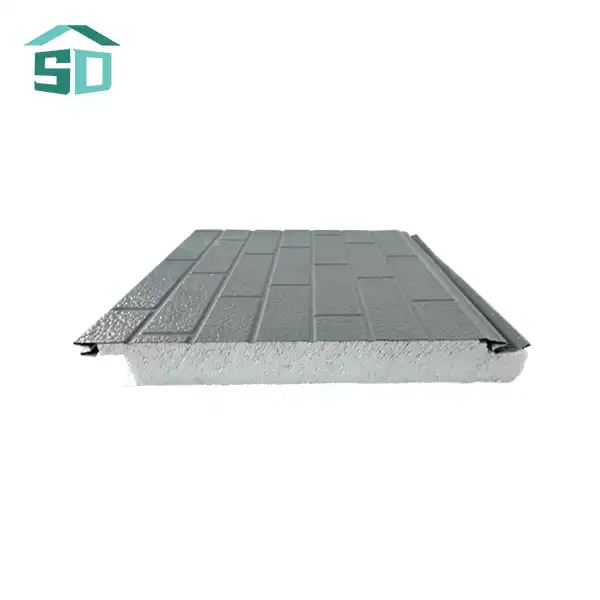

Corrugated sandwich panels are innovative building materials that combine strength, insulation, and aesthetic appeal. These panels typically consist of three main components: two outer layers of corrugated metal sheets and an insulating core material sandwiched between them. The corrugated design of the outer layers provides structural rigidity and enhances the panel's load-bearing capacity.

The core material is often made of polyurethane foam, expanded polystyrene, or mineral wool, offering excellent thermal insulation properties. This unique composition makes corrugated sandwich panels an ideal choice for various construction applications, including industrial buildings, cold storage facilities, and modern architectural designs.

Types of Joints in Corrugated Sandwich Panel Systems

In corrugated sandwich panel systems, several types of joints are commonly encountered:

- Vertical Joints: These run along the height of the building and are typically designed with interlocking profiles to ensure a secure connection between adjacent panels.

- Horizontal Joints: Found between rows of panels, these joints often incorporate drainage channels to direct water away from the building envelope.

- Corner Joints: These occur at the intersection of walls and require special attention to maintain continuity in insulation and weatherproofing.

- Roof-to-Wall Joints: Critical areas where the roof panels meet the wall panels, necessitating careful sealing to prevent water ingress.

Understanding these joint types is crucial for implementing effective sealing and waterproofing strategies. Each joint presents unique challenges and requires specific techniques to ensure a watertight and thermally efficient building envelope.

The Importance of Proper Joint Sealing in Corrugated Sandwich Panel Structures

Proper joint sealing in corrugated sandwich panel structures is paramount for several reasons:

1. Moisture Protection: Sealed joints prevent water infiltration, safeguarding the building's interior and structural integrity.

2. Thermal Efficiency: Well-sealed joints maintain the insulation continuity, reducing heat loss and improving energy efficiency.

3. Air Tightness: Effective sealing minimizes air leakage, enhancing indoor comfort and reducing heating and cooling costs.

4. Structural Longevity: By preventing moisture-related issues, proper sealing extends the lifespan of the sandwich panel system.

5. Acoustic Performance: Sealed joints contribute to better sound insulation, particularly important in industrial or commercial settings.

Neglecting joint sealing can lead to a host of problems, including energy loss, mold growth, and premature deterioration of the building envelope. Therefore, investing in high-quality sealing materials and proper installation techniques is essential for maximizing the benefits of corrugated sandwich panel systems.

Essential Techniques for Sealing Sandwich Panel Joints

Preparation of Joint Surfaces

Before applying any sealant or waterproofing material, thorough preparation of the joint surfaces is crucial. This process involves several key steps:

1. Cleaning: Remove all dust, debris, and contaminants from the joint surfaces using appropriate solvents or cleaning agents. This ensures optimal adhesion of the sealant.

2. Drying: Allow the cleaned surfaces to dry completely. Moisture can compromise the effectiveness of many sealants.

3. Priming: In some cases, applying a primer to the joint surfaces can enhance the bond between the sealant and the corrugated sandwich panel material.

4. Masking: Use masking tape along the edges of the joint to achieve clean, professional-looking sealant lines.

Proper surface preparation is the foundation for successful joint sealing and waterproofing. It significantly impacts the longevity and performance of the sealed joint.

Selection of Appropriate Sealants and Waterproofing Materials

Choosing the right sealants and waterproofing materials is critical for effective joint protection in corrugated sandwich panel systems. Consider the following factors when selecting these materials:

- Compatibility: Ensure the sealant is compatible with the sandwich panel materials to prevent adverse chemical reactions.

- Elasticity: Select sealants with sufficient elasticity to accommodate thermal expansion and contraction of the panels.

- UV Resistance: For exterior applications, choose materials that can withstand prolonged exposure to sunlight without degradation.

- Temperature Range: The sealant should maintain its properties across the expected temperature range of the building's location.

- Durability: Opt for high-quality, long-lasting sealants to minimize maintenance and replacement frequency.

Common types of sealants used for corrugated sandwich panels include silicone-based sealants, polyurethane sealants, and MS polymer sealants. Each has its strengths and is suited to different applications within the sandwich panel system.

Application Techniques for Optimal Sealing

Proper application of sealants and waterproofing materials is crucial for achieving a durable and effective seal. Key techniques include:

1. Joint Design: Ensure the joint is designed with the appropriate width and depth to allow for proper sealant application and movement.

2. Backing Material: Use a backing rod or bond breaker tape to control the depth of the sealant and prevent three-sided adhesion.

3. Tooling: After applying the sealant, use a tooling technique to ensure full contact with joint surfaces and a smooth finish.

4. Overlapping: When sealing long joints, use an overlapping technique to ensure continuity of the seal.

5. Curing: Allow the sealant to cure fully according to the manufacturer's instructions before exposing it to water or stress.

Proper application techniques not only enhance the effectiveness of the seal but also contribute to its longevity and aesthetic appearance. It's often recommended to engage experienced professionals for complex sealing projects to ensure optimal results.

Advanced Waterproofing Solutions for Sandwich Panel Joints

Innovative Membrane Systems for Joint Protection

In addition to traditional sealants, innovative membrane systems offer advanced protection for corrugated sandwich panel joints. These systems typically consist of flexible, self-adhering membranes that can be applied over joints to provide a continuous waterproof barrier. Key features of these membrane systems include:

- High Flexibility: Able to accommodate building movement and thermal expansion without cracking or losing adhesion.

- Self-Sealing Properties: Some membranes can self-seal around fasteners, providing additional protection against water infiltration.

- Vapor Permeability: Certain membranes allow water vapor to escape while preventing liquid water from entering, helping to manage moisture within the building envelope.

- Easy Application: Many membrane systems are designed for simple, peel-and-stick application, reducing installation time and complexity.

These advanced membrane systems are particularly useful for critical areas such as roof-to-wall joints and around openings where traditional sealants may not provide sufficient protection.

Integration of Flashing Systems with Sandwich Panel Joints

Flashing systems play a crucial role in directing water away from vulnerable joint areas in corrugated sandwich panel constructions. Proper integration of flashing with joint sealing techniques enhances the overall waterproofing performance. Consider the following aspects when implementing flashing systems:

1. Material Compatibility: Choose flashing materials that are compatible with both the sandwich panel surface and the sealants used.

2. Overlapping Technique: Ensure that flashing is installed with proper overlaps to create a shingling effect, directing water away from joints.

3. Flexible Flashing: Use flexible flashing materials at complex joint intersections to maintain continuity of the water barrier.

4. End Dams: Incorporate end dams at terminations of horizontal flashing to prevent water from migrating beyond the flashing system.

5. Integration with Sealants: Coordinate the installation of flashing with sealant application to create a cohesive waterproofing system.

Properly integrated flashing systems significantly enhance the water-shedding capabilities of the building envelope, particularly at critical junctions and transitions between different building components.

Cutting-Edge Technologies in Joint Sealing for Corrugated Sandwich Panels

The field of joint sealing for corrugated sandwich panels continues to evolve with the introduction of cutting-edge technologies. Some notable advancements include:

- Smart Sealants: These innovative materials can change properties in response to environmental conditions, providing adaptive protection against moisture and temperature fluctuations.

- Nanotechnology-Enhanced Sealants: Incorporating nanoparticles into sealant formulations can improve adhesion, durability, and self-cleaning properties.

- Hybrid Sealant Systems: Combining different sealant technologies to create products that offer the best properties of multiple sealant types.

- Spray-Applied Liquid Membranes: These systems can be rapidly applied to create a seamless, monolithic waterproofing layer over complex joint configurations.

- IoT-Enabled Moisture Detection: Embedding sensors within joint systems to provide real-time monitoring of moisture levels and early detection of potential leaks.

These advanced technologies offer promising solutions for enhancing the long-term performance and reliability of joint sealing in corrugated sandwich panel structures. As the industry continues to innovate, we can expect even more sophisticated and effective waterproofing solutions to emerge.

Conclusion

Sealing and waterproofing joints in corrugated sandwich panel systems is a critical aspect of building envelope design and maintenance. By understanding the unique properties of these panels, implementing proper sealing techniques, and utilizing advanced waterproofing solutions, builders and property owners can significantly enhance the durability, energy efficiency, and overall performance of their structures. From traditional sealants to innovative membrane systems and cutting-edge technologies, the range of available solutions continues to expand, offering improved protection against moisture infiltration and environmental challenges.

For those seeking expert guidance on corrugated sandwich panel solutions and advanced sealing techniques, Weifang Sandong Building Materials Co., Ltd. stands ready to assist. Our comprehensive range of exterior cladding and facade solutions, including high-quality corrugated sandwich panels, is designed to meet the diverse needs of modern construction projects. To learn more about how we can enhance your building's performance and aesthetics, please contact us at info@sdqsc.com.

FAQ

How often should sandwich panel joints be inspected and resealed?

Regular inspections should be conducted annually, with resealing typically needed every 5-10 years, depending on environmental conditions and sealant quality.

Can corrugated sandwich panels be used in high-moisture environments?

Yes, when properly sealed and waterproofed, corrugated sandwich panels can perform well in high-moisture environments, making them suitable for applications like cold storage facilities.

What are the signs that sandwich panel joints need resealing?

Signs include visible cracks in the sealant, water stains on interior surfaces, drafts, and increased energy bills due to reduced insulation effectiveness.

References

1. Smith, J. (2021). Advanced Sealing Techniques for Modern Building Envelopes. Journal of Construction Engineering, 45(3), 278-295.

2. Johnson, A., & Brown, M. (2020). Innovations in Waterproofing Technologies for Sandwich Panel Systems. Building and Environment, 168, 106502.

3. National Roofing Contractors Association. (2019). The NRCA Roofing Manual: Membrane Roof Systems. Rosemont, IL: NRCA.

4. European Organisation for Technical Approvals. (2018). ETAG 021 - Guideline for European Technical Approval of Cold Storage Premises Kits.

5. International Code Council. (2021). International Building Code. Country Club Hills, IL: ICC.