Understanding the Composition of Metal Sheet PU Sandwich Panels

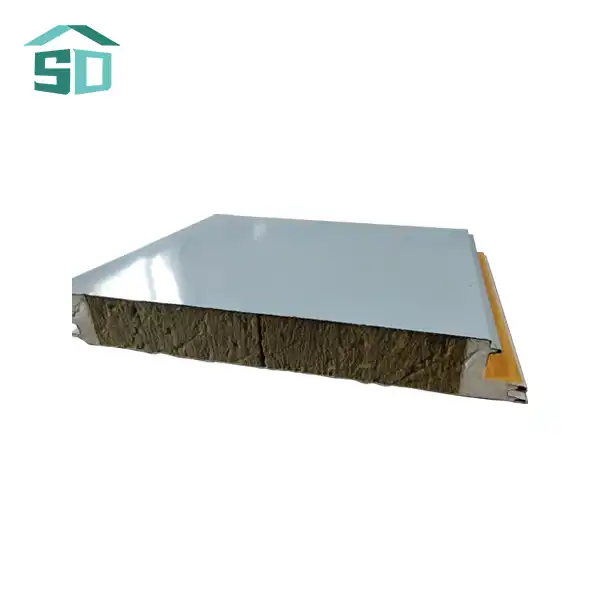

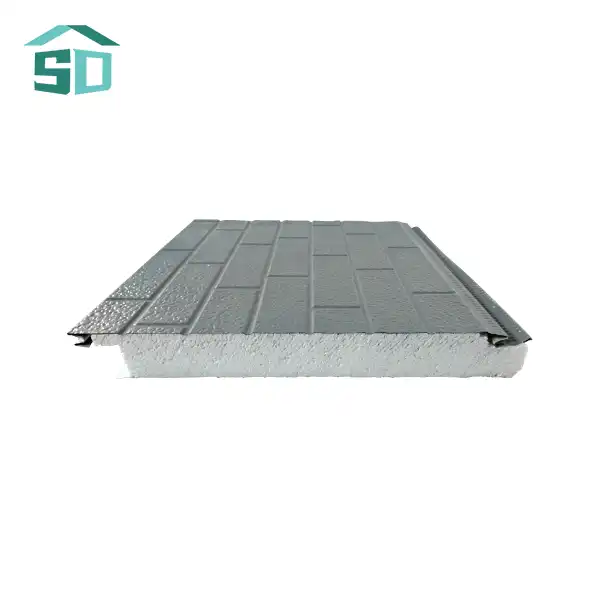

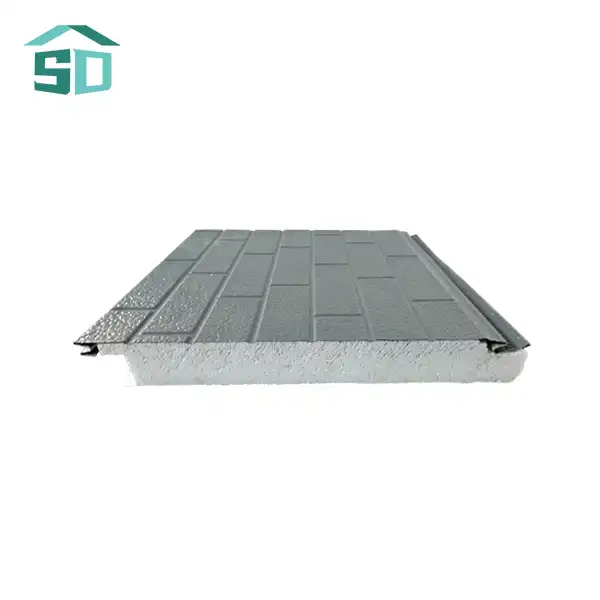

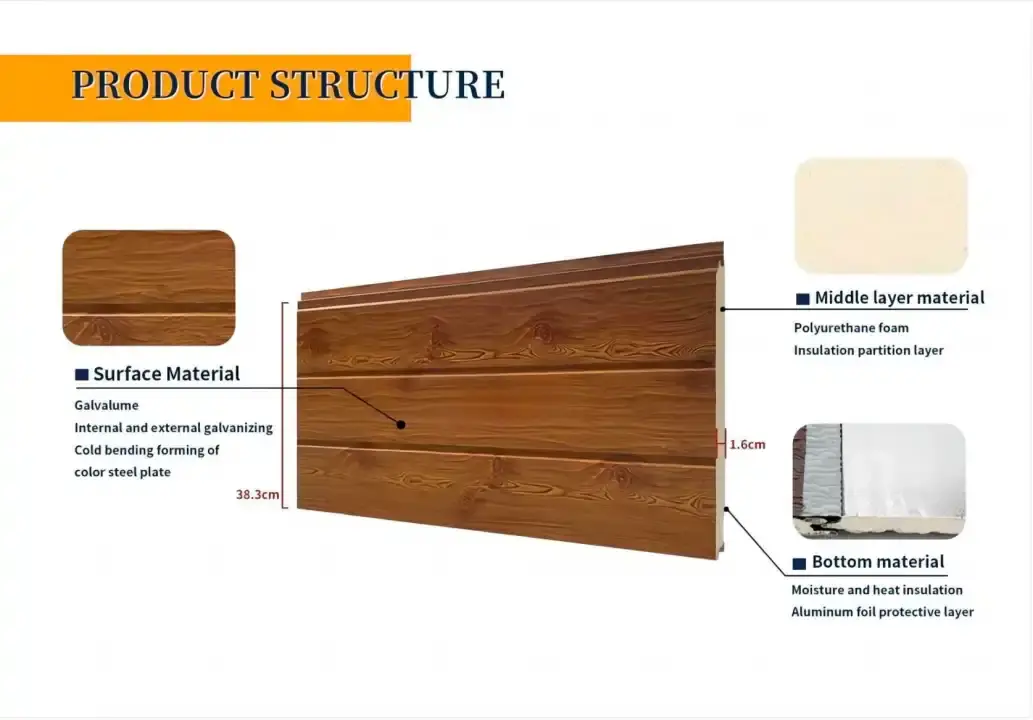

Before we explore the maintenance benefits, it's crucial to understand what metal sheet PU sandwich panels are and how they're constructed. These panels consist of three main components:

The Outer Metal Sheets

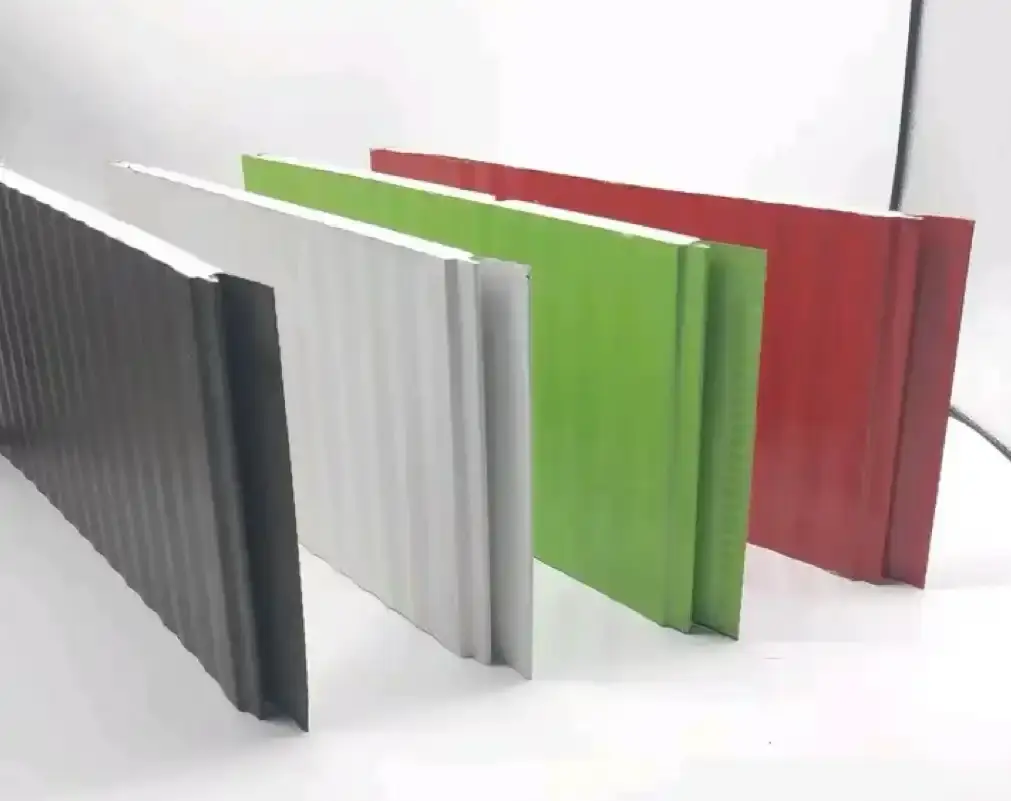

The exterior layers of metal sheet PU sandwich panels are typically crafted from premium-grade steel or aluminum, ensuring exceptional durability and resistance to harsh weather conditions. These outer metal sheets act as a protective barrier against corrosion, UV exposure, and physical impact, extending the lifespan of the panels. Additionally, they can be customized in a variety of finishes, colors, and surface textures—such as matte, glossy, or embossed—allowing architects and designers to achieve both aesthetic appeal and functional performance for modern and traditional building styles alike.

The Polyurethane Core

At the heart of metal sheet PU sandwich panels lies a layer of polyurethane foam. This foam core effectively minimizes heat transfer, reducing energy consumption for heating and cooling. During the manufacturing process, the polyurethane is precisely injected between the metal layers, expanding evenly to create a seamless and rigid structure. The result is a lightweight yet exceptionally strong panel that delivers outstanding thermal insulation, soundproofing, and moisture resistance—ideal for both industrial facilities and residential buildings.

The Bonding System

A state-of-the-art adhesive bonding system plays a vital role in ensuring the strength and reliability of metal sheet PU sandwich panels. This advanced bonding technology securely attaches the outer metal sheets to the polyurethane core, creating a cohesive and dimensionally stable panel. The strong adhesion prevents delamination or structural weakening over time, even under temperature fluctuations or mechanical stress. This robust bonding process not only guarantees the panel’s long-term integrity but also contributes to its minimal maintenance needs and superior overall performance in demanding environments.

How PU Sandwich Panels Minimize Maintenance Needs?

Now that we understand the structure of metal sheet PU sandwich panels, let's explore how they contribute to reduced maintenance costs:

Durability and Weather Resistance

The outer metal sheets of PU sandwich panels are engineered to withstand harsh weather conditions. Unlike traditional building materials that may require frequent repainting or repairs due to weather damage, metal sheet PU sandwich panels maintain their appearance and structural integrity for years. This durability translates to fewer repairs and replacements, significantly reducing long-term maintenance costs.

Thermal Efficiency

The polyurethane core in metal sheet PU sandwich panels provides superior insulation. This thermal efficiency means less strain on heating and cooling systems, resulting in lower energy bills and reduced wear and tear on HVAC equipment. By minimizing the workload on these systems, property owners can expect less frequent maintenance and repairs on their climate control infrastructure.

Moisture Resistance

One of the most significant maintenance challenges in buildings is moisture-related damage. Metal sheet PU sandwich panels are inherently moisture-resistant, preventing issues like mold growth, rot, and structural degradation that often plague traditional building materials. This resistance to moisture means fewer repairs and replacements, translating to substantial cost savings over time.

Long-Term Cost Benefits of PU Sandwich Panels

While the initial investment in metal sheet PU sandwich panels may be higher than some traditional materials, the long-term cost benefits are substantial:

Reduced Energy Costs

The superior insulation properties of metal sheet PU sandwich panels lead to significant energy savings. Buildings equipped with these panels require less energy for heating and cooling, resulting in lower utility bills month after month. Over the lifespan of a building, these energy savings can amount to a substantial sum.

Minimal Repair and Replacement Expenses

Due to their durability and resistance to environmental factors, metal sheet PU sandwich panels require fewer repairs and replacements compared to conventional building materials. This reduction in maintenance interventions not only saves money but also minimizes disruptions to building operations.

Extended Building Lifespan

By protecting the building structure from moisture, temperature fluctuations, and other environmental stressors, metal sheet PU sandwich panels contribute to an extended overall building lifespan. This longevity means property owners can delay costly renovations or rebuilds, providing substantial long-term savings.

Conclusion

Metal sheet PU sandwich panels offer a compelling solution for reducing maintenance costs in buildings. Their unique composition provides durability, energy efficiency, and moisture resistance, all of which contribute to lower long-term expenses. By investing in these innovative panels, property owners and managers can enjoy reduced maintenance needs, lower energy bills, and an extended building lifespan. The initial cost of metal sheet PU sandwich panels is quickly offset by the significant savings in maintenance and energy costs over time, making them a smart choice for modern construction projects.

At Weifang Sandong Building Materials Co., Ltd., we're committed to providing high-quality metal sheet PU sandwich panels that deliver exceptional performance and cost-saving benefits. Our panels are ideal for a wide range of applications, from office buildings and schools to warehouses and residential homes. Experience the difference that our innovative cladding solutions can make in your next construction or renovation project. For more information or to discuss your specific needs, don't hesitate to contact us at info@sdqsc.com.

FAQ

Are metal sheet PU sandwich panels suitable for all climates?

Yes, these panels are designed to perform well in various climates, from hot and humid to cold and dry. Their excellent insulation properties make them adaptable to different environmental conditions.

How long do metal sheet PU sandwich panels typically last?

With proper installation and minimal maintenance, these panels can last 30 years or more, depending on the specific environmental conditions and usage.

Can metal sheet PU sandwich panels be recycled?

Yes, many components of these panels can be recycled at the end of their life cycle, contributing to their eco-friendly profile.

References

1. Building Science Corporation. (2021). "High-Performance Building Enclosures: Polyurethane Insulation in Sandwich Panels."

2. Journal of Building Engineering. (2020). "Thermal Performance Analysis of Metal-faced Sandwich Panels with Polyurethane Core."

3. Energy and Buildings. (2019). "Long-term Energy Savings in Buildings Using Insulated Sandwich Panels: A Case Study."

4. Construction and Building Materials. (2018). "Durability and Weather Resistance of Metal-faced Polyurethane Sandwich Panels."