- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Corrugated Steel Panels for Modern Warehouse Design

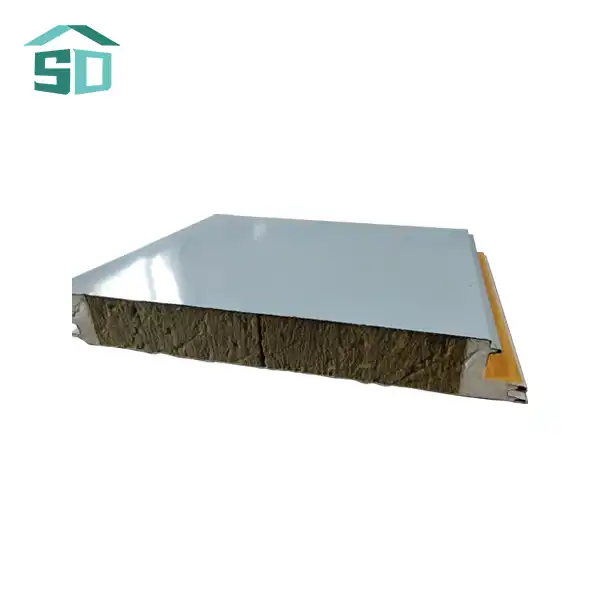

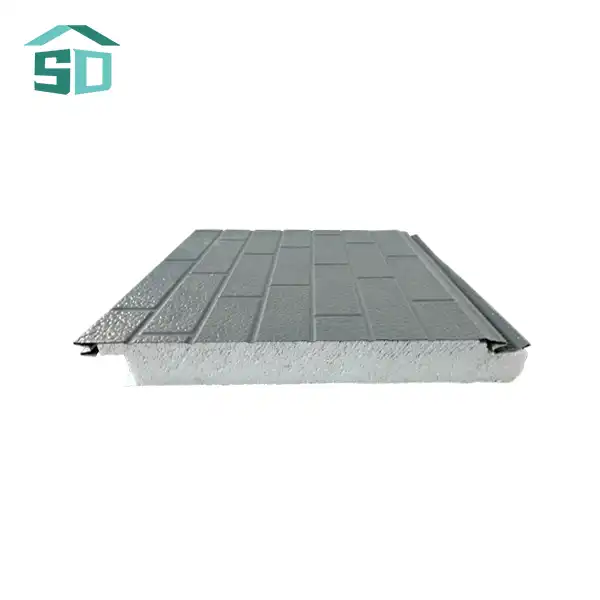

Corrugated steel siding panels have revolutionized modern warehouse design, offering a perfect blend of functionality and aesthetics. These versatile building materials provide robust structural integrity while enhancing the visual appeal of industrial spaces. With their distinctive wave-like pattern, corrugated steel panels not only withstand harsh weather conditions but also contribute to energy efficiency and cost-effectiveness. As architects and builders seek innovative solutions for contemporary warehouses, corrugated steel panels emerge as a top choice, seamlessly combining durability, style, and practicality in one remarkable package.

The Rise of Corrugated Steel in Industrial Architecture

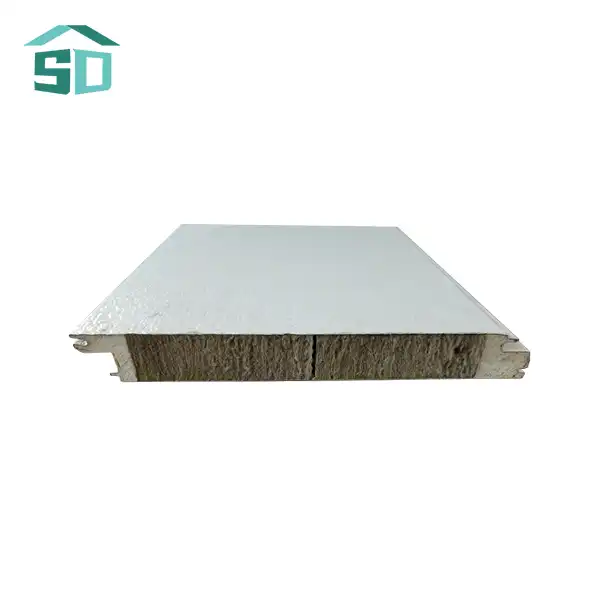

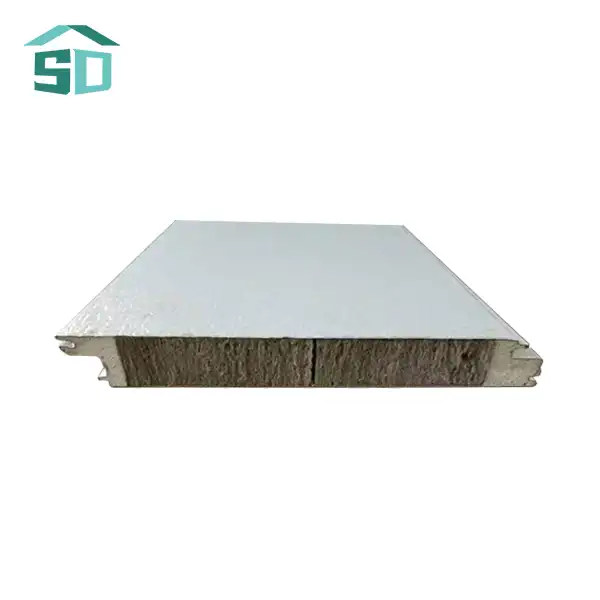

Corrugated steel panels have become increasingly popular in industrial architecture, particularly in warehouse design. Their unique properties make them an ideal choice for large-scale structures that require both strength and flexibility. The corrugated pattern adds rigidity to the panels, allowing them to span greater distances without additional support. This structural efficiency translates to cost savings in construction and maintenance.

Modern warehouses benefit from the lightweight nature of corrugated steel panels, which reduces the overall load on the building's foundation. This characteristic is especially advantageous in areas with poor soil conditions or seismic activity. The panels' ability to distribute weight evenly across the structure enhances the warehouse's stability and longevity.

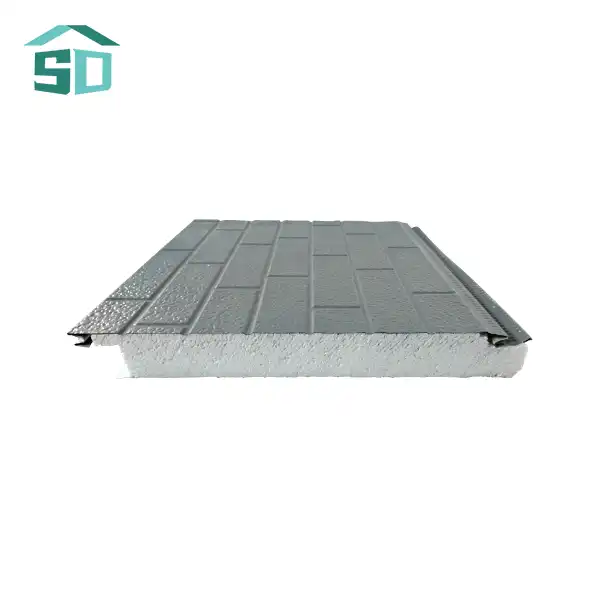

Architects appreciate the versatility of corrugated steel siding panels in creating dynamic facades. The play of light and shadow on the undulating surface adds visual interest to what might otherwise be a plain, box-like structure. By varying the orientation, spacing, and finish of the panels, designers can achieve a range of aesthetic effects, from sleek and modern to industrial chic.

Environmental Benefits of Corrugated Steel Panels

Sustainability is a key consideration in modern warehouse design, and corrugated steel panels offer significant environmental advantages. These panels are often made from recycled materials and are themselves fully recyclable at the end of their life cycle. This circularity reduces the environmental impact of warehouse construction and aligns with green building practices.

Corrugated steel panels contribute to energy efficiency in warehouses. Their reflective properties help to reduce heat absorption, keeping the interior cooler in hot climates and reducing the need for air conditioning. In colder regions, the panels can be insulated to retain heat, further optimizing energy consumption. This thermal performance not only lowers operational costs but also minimizes the warehouse's carbon footprint.

Design Flexibility and Customization Options

One of the most compelling aspects of corrugated steel panels for modern warehouse design is their remarkable flexibility. Architects and builders can choose from a wide array of panel profiles, each offering unique aesthetic and functional properties. From deep, dramatic waves to subtle, shallow corrugations, the options allow for customized appearances that can complement any architectural vision.

Color customization adds another layer of design potential to corrugated steel panels. Modern coating technologies offer a vast spectrum of colors and finishes, from matte earth tones to vibrant metallic sheens. This versatility enables warehouses to blend seamlessly with their surroundings or stand out as bold architectural statements. Additionally, specialized coatings can enhance the panels' resistance to corrosion, UV radiation, and even graffiti, ensuring that the warehouse maintains its appearance over time.

Innovative uses of corrugated steel siding panels extend beyond exterior cladding. Interior applications are gaining popularity, with panels being used to create textured walls, ceilings, and partitions within warehouses. This continuity between exterior and interior design elements creates a cohesive aesthetic while maximizing the benefits of the material throughout the structure.

Integration with Modern Building Systems

Corrugated steel panels integrate seamlessly with other modern building systems, enhancing the overall functionality of warehouses. For instance, they can be easily combined with solar panel installations, turning the warehouse roof into an energy-generating asset. The panels' structural properties also make them compatible with advanced ventilation systems, allowing for the incorporation of natural airflow solutions that improve indoor air quality and reduce reliance on mechanical systems.

The adaptability of corrugated steel panels extends to future modifications and expansions. As warehouse needs evolve, these panels can be easily removed, replaced, or reconfigured without compromising the integrity of the structure. This flexibility ensures that the warehouse can adapt to changing business requirements, technological advancements, and regulatory standards over its lifetime.

Performance and Longevity in Warehouse Applications

The durability of corrugated steel panels is a crucial factor in their popularity for warehouse design. These panels are engineered to withstand extreme weather conditions, including high winds, heavy snow loads, and intense UV exposure. The corrugated profile enhances the panels' strength-to-weight ratio, allowing them to resist deformation and maintain their structural integrity over decades of use.

Corrosion resistance is another key performance attribute of modern corrugated steel panels. Advanced galvanization and coating processes create a protective barrier that prevents rust and deterioration, even in harsh industrial environments or coastal areas with high salt content in the air. This resistance to corrosion translates to reduced maintenance requirements and lower long-term operational costs for warehouse owners.

Fire safety is a critical consideration in warehouse design, and corrugated steel siding panels offer superior fire resistance compared to many traditional building materials. The non-combustible nature of steel helps to contain fires and prevent their spread, providing valuable time for evacuation and fire suppression efforts. This inherent fire resistance can lead to reduced insurance premiums and compliance with stringent safety regulations.

Cost-Effectiveness Over the Building Lifecycle

While the initial investment in corrugated steel panels may be higher than some alternative materials, their long-term cost-effectiveness is compelling. The durability and low maintenance requirements of these panels result in significant savings over the life of the warehouse. Reduced need for repairs, repainting, and replacement translates to lower operational expenses and less downtime for maintenance activities.

The energy efficiency benefits of corrugated steel panels contribute to ongoing cost savings through reduced heating and cooling expenses. In some regions, the use of these panels may qualify warehouse projects for energy efficiency incentives or tax rebates, further improving the return on investment for building owners.

Conclusion

Corrugated steel siding panels have emerged as a transformative element in modern warehouse design, offering a harmonious blend of form and function. Their structural strength, design flexibility, and environmental benefits make them an ideal choice for architects and builders seeking to create efficient, sustainable, and visually appealing industrial spaces. As warehouses continue to evolve to meet the demands of a rapidly changing global economy, corrugated steel panels stand ready to provide the foundation for innovative and enduring architectural solutions.

At Weifang Sandong Building Materials Co., Ltd., we understand the unique challenges and opportunities presented by modern warehouse design. Our corrugated steel panels are engineered to meet the highest standards of quality, durability, and aesthetic appeal. Whether you're planning a new construction project or renovating an existing facility, our team of experts is ready to help you harness the full potential of corrugated steel panels for your warehouse needs. Contact us today at info@sdqsc.com to explore how our innovative building solutions can elevate your next project.

FAQ

What are the main advantages of using corrugated steel panels in warehouse design?

Corrugated steel panels offer structural strength, design flexibility, energy efficiency, and long-term durability. They are lightweight, weather-resistant, and can be customized to meet specific aesthetic and functional requirements.

How do corrugated steel panels contribute to sustainable warehouse design?

These panels are often made from recycled materials and are recyclable at the end of their life. They also enhance energy efficiency by reflecting heat and can be integrated with solar panels and natural ventilation systems.

Are corrugated steel panels suitable for all climates?

Yes, corrugated steel panels are designed to withstand a wide range of climatic conditions, from extreme heat to heavy snow loads. Their corrosion resistance makes them suitable for coastal areas as well.

References

1.American Iron and Steel Institute. (2022). "Steel in Construction: Sustainable Solutions for Modern Buildings."

2.Building Design & Construction. (2021). "Trends in Industrial Architecture: The Rise of Corrugated Steel."

3.Journal of Architectural Engineering. (2023). "Thermal Performance of Corrugated Steel Panels in Large-Scale Structures."

4.International Journal of Sustainable Building Technology and Urban Development. (2022). "Life Cycle Assessment of Corrugated Steel Panels in Warehouse Construction."