The Evolution of Corrugated Sandwich Panels in Modular Construction

Historical Development of Sandwich Panels

The concept of sandwich panels dates back to the mid-20th century, with its roots in aerospace engineering. Initially developed for aircraft construction, these panels were prized for their high strength-to-weight ratio. As the technology matured, the construction industry began to recognize the potential of sandwich panels for building applications. The introduction of corrugated sandwich panels marked a significant milestone in this evolution, offering enhanced structural stability and versatility.

In the 1960s and 1970s, early adopters in the construction sector started experimenting with sandwich panels for industrial buildings and cold storage facilities. The panels' excellent insulation properties and ease of installation made them an attractive option for these applications. However, it wasn't until the late 20th century that corrugated sandwich panels began to make inroads into residential construction, particularly in the realm of modular homes.

Advancements in Materials and Manufacturing

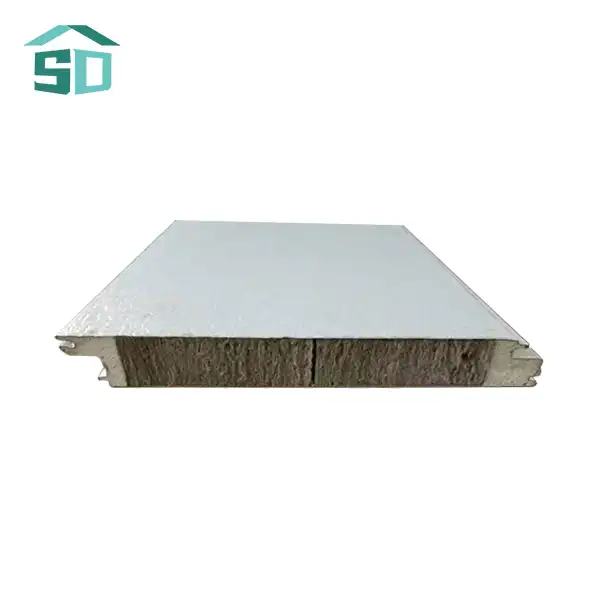

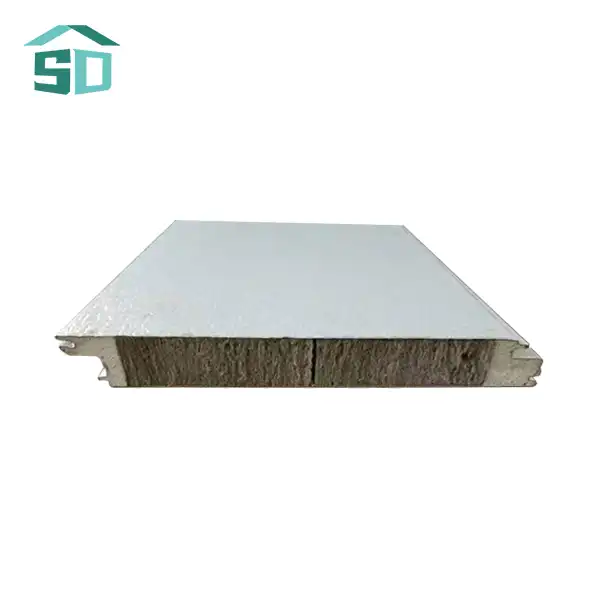

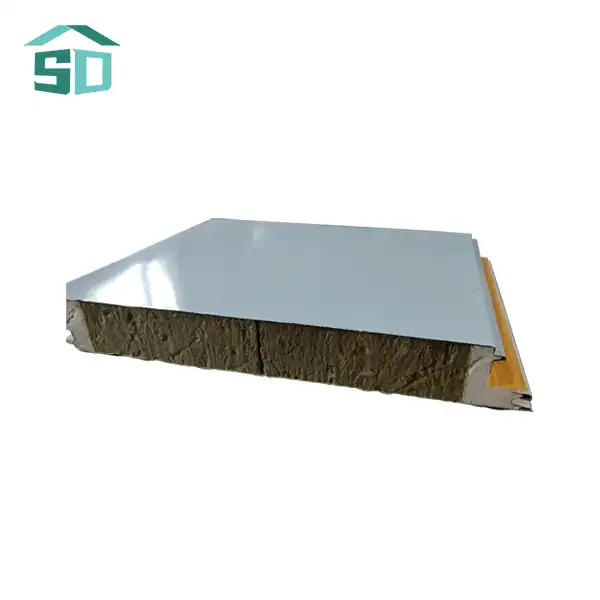

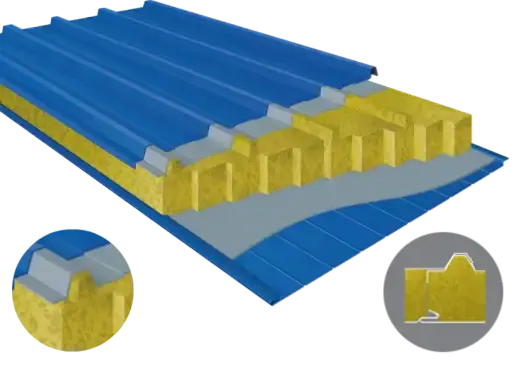

The development of corrugated sandwich panels has been closely tied to advancements in materials science and manufacturing processes. Early panels were primarily made with plywood or particle board facings and a foam core. Today's corrugated sandwich panels utilize a wide range of materials, including steel, aluminum, fiber-reinforced polymers, and various insulating cores such as polyurethane, polyisocyanurate, and mineral wool.

Modern manufacturing techniques have greatly improved the quality and consistency of corrugated sandwich panels. Computer-aided design and automated production lines ensure precise dimensions and uniform material distribution. This level of precision is crucial for modular construction, where components must fit together seamlessly. Additionally, innovations in coating technologies have enhanced the panels' resistance to corrosion, UV radiation, and fire, making them suitable for diverse environmental conditions.

Integration into Modular Construction Systems

The adoption of corrugated sandwich panels in modular home construction has been driven by the growing demand for faster, more efficient building methods. Modular construction, which involves fabricating sections of a building off-site and then assembling them on-site, aligns perfectly with the pre-fabricated nature of sandwich panels. This synergy has led to the development of integrated systems where corrugated sandwich panels serve not only as wall and roof elements but also as structural components.

Corrugated sandwich panel manufacturers have responded to this trend by developing specialized panel designs tailored for modular homes. These panels often feature built-in connection systems, allowing for rapid assembly and disassembly. Some advanced panels even incorporate electrical and plumbing conduits, further streamlining the construction process. As modular construction techniques continue to evolve, corrugated sandwich panels are playing an increasingly central role in shaping the future of residential building.

Benefits of Using Corrugated Sandwich Panels in Modular Homes

Structural Integrity and Lightweight Design

One of the primary advantages of corrugated sandwich panels in modular home construction is their exceptional structural integrity coupled with a lightweight design. The corrugated structure of these panels provides superior strength and rigidity compared to flat panels of similar thickness. This structural efficiency allows for larger spans and fewer supporting elements, resulting in more open and flexible interior spaces.

The lightweight nature of corrugated sandwich panels offers several benefits in the context of modular construction. It reduces the overall weight of the building modules, making transportation and handling easier and more cost-effective. This is particularly advantageous for modular homes that need to be transported long distances or installed in areas with limited access. Furthermore, the reduced weight translates to lower foundation requirements, potentially reducing construction costs and expanding the range of suitable building sites.

Thermal Insulation and Energy Efficiency

Corrugated sandwich panels excel in providing superior thermal insulation, a critical factor in modern home design. The insulating core material, typically polyurethane or mineral wool, offers excellent R-values, significantly reducing heat transfer through walls and roofs. This high level of insulation contributes to increased energy efficiency, leading to lower heating and cooling costs for homeowners.

The design of corrugated sandwich panels also helps minimize thermal bridging, a common issue in traditional construction methods. By providing a continuous insulation layer, these panels reduce the energy loss typically associated with studs or other structural elements. This results in more consistent indoor temperatures and improved overall comfort. Additionally, the airtight nature of properly installed sandwich panels contributes to better control of air infiltration, further enhancing the home's energy performance.

Speed of Construction and Cost-Effectiveness

Perhaps one of the most compelling advantages of using corrugated sandwich panels in modular home construction is the significant reduction in construction time. These panels are designed for rapid installation, often requiring minimal on-site preparation. The pre-fabricated nature of the panels means that large sections of walls or roofs can be put in place quickly, dramatically reducing the overall build time compared to traditional construction methods.

The speed of construction translates directly into cost savings. Reduced on-site labor requirements and shorter project durations lead to lower overall construction costs. Moreover, the precision manufacturing of corrugated sandwich panels results in less material waste, further contributing to cost efficiency. When considering the long-term benefits, such as reduced energy costs and lower maintenance requirements, the use of these panels in modular homes presents a compelling value proposition for both builders and homeowners.

Design Considerations and Architectural Possibilities

Aesthetic Versatility of Corrugated Sandwich Panels

Corrugated sandwich panels offer a wide range of aesthetic possibilities, challenging the notion that modular homes must have a uniform or industrial appearance. These panels come in various finishes, colors, and textures, allowing architects and designers to create visually striking and diverse facades. The corrugated profile itself can be leveraged as a design element, creating interesting shadow patterns and adding depth to the building's exterior.

Corrugated sandwich panels now offer options that mimic traditional building materials such as wood, stone, or brick. This versatility allows modular homes to blend seamlessly into various architectural contexts, from urban environments to rural settings. Additionally, the panels can be easily customized with cut-outs for windows, doors, and other architectural features, providing flexibility in design without compromising the structural integrity or insulation properties.

Customization and Modular Flexibility

The modular nature of corrugated sandwich panels lends itself well to customization and flexible design. Architects can mix and match different panel types, orientations, and finishes to create unique visual effects. This modular approach also facilitates future modifications or expansions to the home, as panels can be easily replaced or added without major structural changes.

Advanced manufacturing techniques allow for the integration of custom features directly into the panels during production. This can include pre-cut openings for utilities, built-in channels for wiring or plumbing, and even embedded smart home technologies. Such customization not only enhances the functionality of the modular home but also streamlines the construction process, reducing the need for on-site modifications.

Sustainable Design and Environmental Considerations

Sustainability is an increasingly important factor in modern home design, and corrugated sandwich panels offer several environmental benefits. The energy efficiency provided by these panels contributes to reduced carbon emissions over the life of the building. Many corrugated sandwich panel manufacturers use recycled materials in their products and design them for easy disassembly and recycling at the end of their life cycle.

The precision manufacturing of these panels results in minimal waste during production and installation, addressing the issue of construction waste that plagues traditional building methods. Furthermore, the longevity and durability of corrugated sandwich panels mean less frequent replacements and renovations, reducing the overall environmental impact of the building over time. As the construction industry moves towards more sustainable practices, the use of these panels in modular homes aligns well with green building certifications and standards.

Conclusion

Corrugated sandwich panels have proven to be a transformative element in modular home construction, offering a perfect blend of efficiency, sustainability, and design flexibility. Their ability to provide excellent structural integrity while maintaining a lightweight profile makes them ideal for the modular construction process. The superior thermal insulation properties of these panels contribute significantly to energy-efficient homes, aligning with modern environmental standards and homeowner expectations.

As the construction industry continues to evolve towards more sustainable and efficient practices, corrugated sandwich panels are poised to play an increasingly important role in shaping the future of residential architecture. For those interested in exploring innovative solutions for modular home construction, corrugated sandwich panels offer a compelling option worth considering. To learn more about our cutting-edge corrugated sandwich panel solutions for your next modular home project, please contact us at info@sdqsc.com.

FAQs

What are the main advantages of using corrugated sandwich panels in modular home construction?

Corrugated sandwich panels offer structural strength, excellent insulation, lightweight design, rapid installation, and versatile aesthetics, making them ideal for efficient and customizable modular home construction.

How do corrugated sandwich panels contribute to energy efficiency in homes?

These panels provide superior thermal insulation, minimize thermal bridging, and create an airtight envelope, significantly reducing heating and cooling costs and improving overall energy performance.

Can corrugated sandwich panels be customized for different architectural styles?

Yes, these panels come in various finishes, colors, and textures, and can be customized to mimic traditional materials, allowing for diverse architectural expressions in modular home design.

References

1. Davies, J. M. (2001). Lightweight sandwich construction. John Wiley & Sons.

2. Lawson, M., Ogden, R., & Goodier, C. (2014). Design in modular construction. CRC Press.

3. Zenkert, D. (1997). The handbook of sandwich construction. Engineering Materials Advisory Services Ltd.

4. Ramakrishna, S., & Hamada, H. (2005). Advances in composite materials for medicine and nanotechnology. BoD–Books on Demand.

5. Pohl, J. (2009). Building science: Concepts and application. John Wiley & Sons.