The Evolution of Insulated Sandwich Panels in Construction

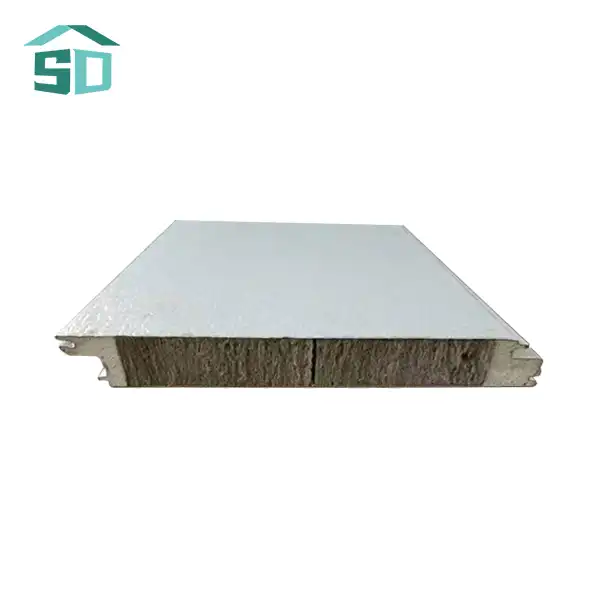

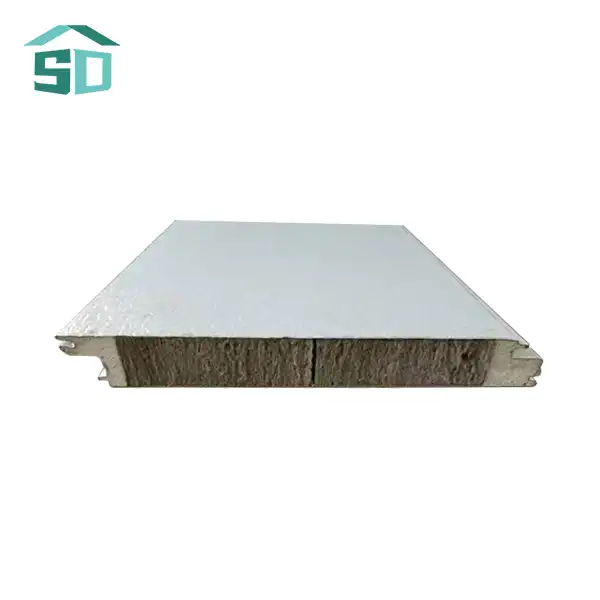

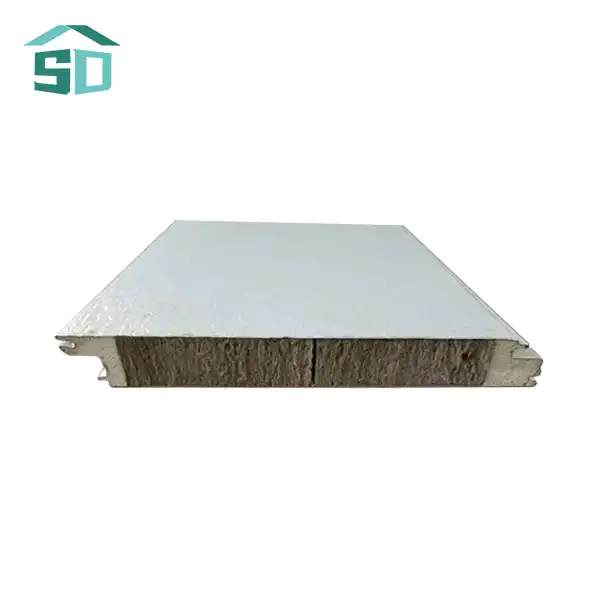

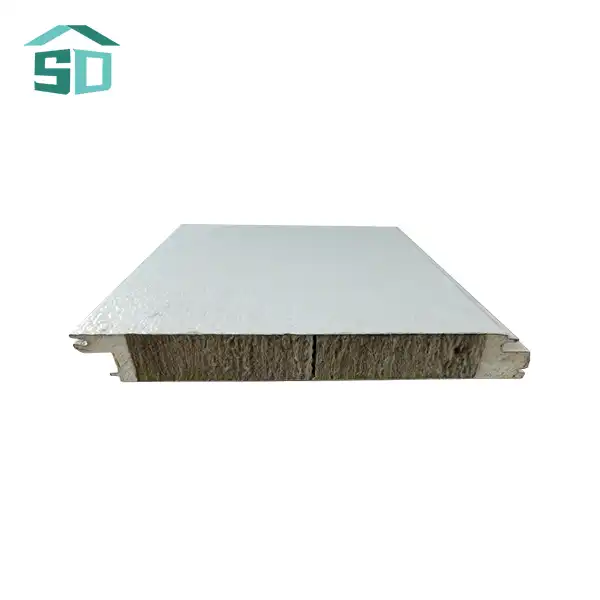

Insulated sandwich panels have come a long way since their inception. Originally developed as a lightweight, insulating material for aerospace applications, these panels have found their way into the construction industry, transforming building practices. The core concept of an insulated sandwich panel remains unchanged – two outer layers of durable material sandwiching an insulating core. However, advancements in materials science and manufacturing processes have significantly enhanced their performance and versatility.

Modern insulated sandwich panels boast impressive thermal properties, thanks to high-performance insulating materials like polyurethane, polystyrene, rock wool, and glass wool. These materials provide excellent temperature regulation, reducing heating and cooling costs while maintaining a comfortable indoor environment. The outer layers, typically made of aluminum, steel, stainless steel, or copper, offer durability and weather resistance, protecting the insulating core and enhancing the overall lifespan of the structure.

The evolution of insulated sandwich panels has also seen improvements in fire safety. Many panels now achieve relevant fire safety standards, making them suitable for a wide range of building types and applications. This advancement has been crucial in expanding the use of these panels in commercial and industrial settings where fire safety is paramount.

Customization and Aesthetic Appeal

One of the most significant developments in insulated sandwich panel technology is the ability to customize their appearance. Manufacturers now offer a wide range of color options and surface treatments, including coating, painting, and anodizing. This flexibility allows architects and designers to create visually striking buildings without compromising on performance. The ability to match patterns and colors to any décor has made insulated sandwich panels a favorite among those seeking both functionality and aesthetic appeal in their building projects.

The Impact of Insulated Sandwich Panels on Rapid Building Techniques

The construction industry is constantly seeking ways to build faster, more efficiently, and with less environmental impact. Insulated sandwich panels have emerged as a game-changer in this regard, offering numerous advantages that align perfectly with the goals of rapid building techniques.

One of the most significant benefits of using insulated sandwich panels is the speed of installation. Traditional construction methods often involve multiple steps and materials to achieve the desired insulation and structural integrity. In contrast, insulated sandwich panels come as pre-fabricated units that can be quickly and easily installed on-site. This streamlined process significantly reduces construction time, allowing projects to be completed faster and with less labor.

The simplified installation process of insulated sandwich panels also contributes to cost savings. With fewer materials to manage and less time required for installation, labor costs are reduced. Additionally, the precision manufacturing of these panels means less waste on the construction site, further improving efficiency and reducing environmental impact.

Energy Efficiency and Sustainability

Insulated sandwich panels play a crucial role in creating energy-efficient buildings. Their superior insulation properties help maintain consistent indoor temperatures, reducing the load on heating and cooling systems. This not only leads to lower energy costs for building occupants but also contributes to reduced carbon emissions over the lifetime of the building.

Moreover, many insulated sandwich panels are made from recyclable materials and are designed to support sustainable building practices. As the construction industry faces increasing pressure to adopt more environmentally friendly methods, the use of these panels aligns well with green building initiatives and certifications.

Versatility and Applications of Insulated Sandwich Panels

The versatility of insulated sandwich panels is one of their most compelling features. These panels can be used in a wide range of applications, from residential to commercial and industrial projects. In the residential sector, they are increasingly being used for exterior walls, roofs, and even interior partitions. Their excellent insulation properties make them particularly suitable for energy-efficient home designs.

In commercial and industrial settings, insulated sandwich panels shine in applications such as warehouses, cold storage facilities, and manufacturing plants. Their ability to maintain specific temperature and humidity levels makes them ideal for controlled environment rooms and food processing facilities. The panels' durability and resistance to harsh weather conditions also make them suitable for outdoor applications and structures in challenging climates.

The transportation industry has also embraced insulated sandwich panels, using them in the construction of vehicles, trailers, and refrigerated vans. Their lightweight nature combined with strong insulation properties makes them perfect for mobile applications where energy efficiency and temperature control are critical.

Modular and Prefabricated Construction

Insulated sandwich panels are playing a pivotal role in the growing trend of modular and prefabricated construction. Their standardized sizes and ease of assembly make them ideal for off-site construction methods. Buildings can be largely assembled in controlled factory environments and then quickly erected on-site, drastically reducing construction time and improving quality control.

This approach is particularly beneficial for projects in remote or challenging locations, where traditional construction methods might be impractical or costly. The use of insulated sandwich panels in modular construction also allows for greater flexibility, as buildings can be easily expanded, modified, or even relocated if needed.

Conclusion

Insulated sandwich panels are undoubtedly shaping the future of rapid building techniques. Their combination of efficiency, versatility, and sustainability makes them an invaluable tool in modern construction. As the industry continues to evolve, these panels are likely to play an even more significant role in addressing the challenges of fast, cost-effective, and environmentally conscious building practices. The ongoing advancements in materials and manufacturing processes promise to further enhance the capabilities of insulated sandwich panels, solidifying their position as a cornerstone of innovative construction techniques.

Are you ready to revolutionize your next construction project with insulated sandwich panels? Weifang Sandong Building Materials Co., Ltd. offers a wide range of high-quality insulated sandwich panels designed to meet your specific needs. From customizable sizes and thicknesses to various insulation materials and fire ratings, we have the perfect solution for your rapid building requirements. Contact us at info@sdqsc.com to learn more about how our insulated sandwich panels can transform your construction process and deliver superior results.

FAQ

What are the main advantages of using insulated sandwich panels in construction?

Insulated sandwich panels offer superior insulation, quick installation, durability, aesthetic flexibility, and contribute to energy efficiency and sustainability in buildings.

Are insulated sandwich panels suitable for all types of buildings?

Yes, these panels are versatile and can be used in residential, commercial, industrial, and even transportation applications due to their adaptability and performance.

How do insulated sandwich panels contribute to rapid building techniques?

They significantly reduce construction time through their pre-fabricated nature, simple installation process, and compatibility with modular construction methods.

References

1. Building Design + Construction. (2021). "The benefits of insulated metal panels for building envelopes."

2. Construction Specifier. (2020). "Insulated metal panels: High-performance building envelope solution."

3. Journal of Building Engineering. (2019). "Thermal performance of insulated sandwich panels in building envelopes: A comprehensive review." Volume 26, 100899.