The Science Behind Insulated Thermal Wall Panels

Insulated thermal wall panels are marvels of modern engineering. They combine robust exterior materials with high-performance insulation cores to create a barrier that's both thermally efficient and moisture-resistant. But what makes these panels so effective against moisture?

Composition and Structure

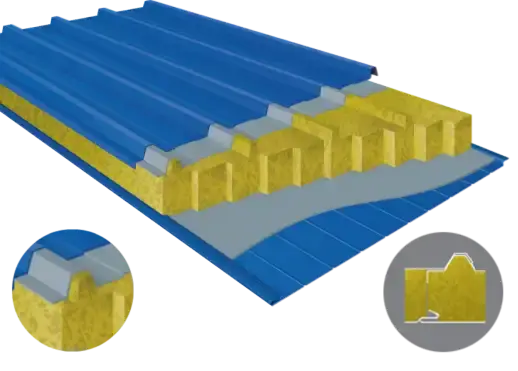

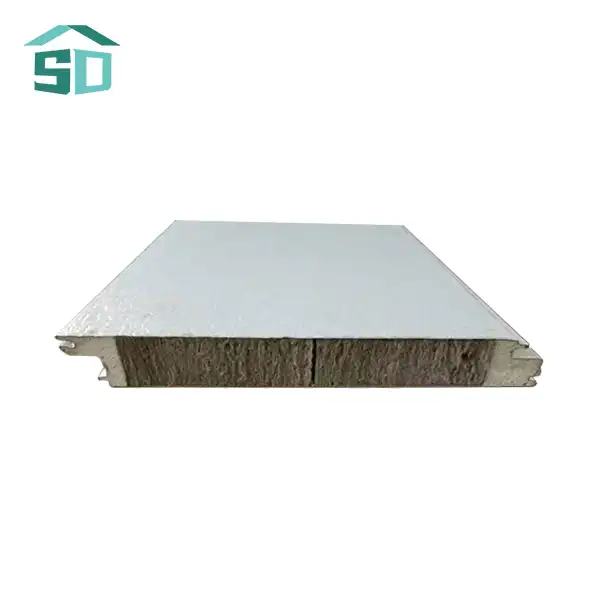

The secret lies in the layered composition of insulated thermal wall panels. Typically, these panels consist of three main components:

1. Exterior Face: Usually made of materials like steel, aluminum, or other weather-resistant metals

2. Insulation Core: Composed of materials such as polyurethane, polystyrene, rock wool, or glass wool

3. Interior Face: Often similar to the exterior, providing structural integrity and a finished look

This sandwich-like structure creates a formidable barrier against moisture infiltration. The metal faces are inherently water-resistant, while the insulation core is designed to repel moisture and prevent condensation within the panel itself.

Advanced Moisture Management

Insulated thermal wall panels employ sophisticated moisture management techniques. Many panels feature vapor barriers or breathable membranes that allow moisture to escape while preventing water from entering. This bi-directional moisture control is crucial in maintaining a dry, healthy building envelope.

Moreover, the joints between panels are engineered with precision. Interlocking systems and specialized sealants ensure that there are no weak points where moisture could potentially infiltrate. This comprehensive approach to moisture management makes insulated thermal wall panels a superior choice for buildings in any climate.

Benefits Beyond Moisture Protection

While their moisture-fighting capabilities are impressive, insulated thermal wall panels offer a plethora of other benefits that make them an attractive option for modern construction projects.

Energy Efficiency Excellence

Insulated thermal wall panels are champions of energy efficiency. Their high-performance insulation cores significantly reduce heat transfer, leading to lower heating and cooling costs. This efficiency isn't just good for your wallet; it's great for the environment too, reducing the overall carbon footprint of buildings.

The thermal performance of these panels is often measured by their R-value, which indicates the insulation's resistance to heat flow. Insulated thermal wall panels typically boast impressive R-values, outperforming many traditional insulation methods.

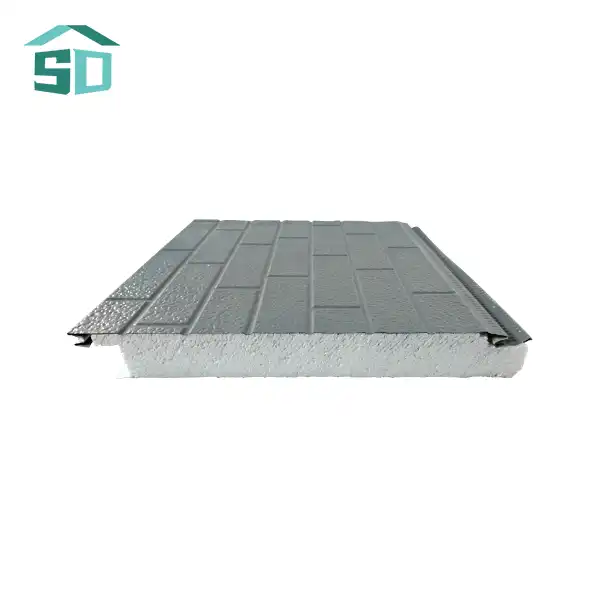

Aesthetic Versatility

Gone are the days when insulation meant sacrificing style. Modern insulated thermal wall panels come in a vast array of colors, textures, and finishes. Whether you're aiming for a sleek, contemporary look or a more traditional aesthetic, there's likely a panel design to match your vision.

Some manufacturers even offer customizable options, allowing architects and designers to create unique patterns or incorporate branding elements directly into the building's exterior. This versatility makes insulated thermal wall panels a favorite among design-conscious builders and property owners.

Durability and Longevity

Insulated thermal wall panels are built to last. Their robust construction makes them resistant to many of the factors that typically degrade building materials over time. They stand up well to:

- UV radiation

- Extreme temperatures

- Wind and rain

- Physical impacts

This durability translates to lower maintenance costs and a longer lifespan for the building envelope. Many manufacturers offer warranties of 20 years or more on their insulated thermal wall panels, reflecting confidence in the product's longevity.

Installation and Maintenance: Simplicity Meets Efficiency

One of the most appealing aspects of insulated thermal wall panels is their ease of installation and low maintenance requirements. This simplicity contributes significantly to their growing popularity in both new construction and renovation projects.

Streamlined Installation Process

Installing insulated thermal wall panels is a remarkably straightforward process, especially when compared to traditional insulation methods. The panels are designed for quick and easy assembly, often utilizing a tongue-and-groove system or similar interlocking mechanism.

This simplified installation offers several advantages:

- Reduced Labor Costs: Fewer man-hours are required for installation, leading to significant cost savings.

- Faster Project Completion: The speed of installation can dramatically reduce overall construction time.

- Minimal On-Site Waste: Pre-fabricated panels mean less cutting and waste at the construction site.

- Consistent Quality: Factory-made panels ensure uniform insulation and finish quality across the entire building.

Many insulated thermal wall panel manufacturers provide detailed installation guides and even offer training for contractors, ensuring that the panels are installed correctly for optimal performance.

Low-Maintenance Performance

Once installed, insulated thermal wall panels require minimal maintenance to continue performing at their best. Their durable exterior surfaces resist staining, fading, and physical damage, often needing nothing more than occasional cleaning to maintain their appearance.

In the rare event that a panel does become damaged, individual panels can typically be replaced without disturbing the surrounding wall system. This modular nature makes repairs simple and cost-effective, especially when compared to traditional wall systems.

The low maintenance requirements of insulated thermal wall panels contribute to their overall cost-effectiveness. Building owners can expect to see savings not just in energy costs, but also in long-term maintenance and repair expenses.

Conclusion

Insulated thermal wall panels represent a significant leap forward in building technology. Their superior moisture resistance, combined with excellent thermal performance, aesthetic versatility, and ease of installation, makes them an ideal choice for a wide range of construction projects. As we continue to seek more efficient, durable, and sustainable building solutions, insulated thermal wall panels are poised to play an increasingly important role in shaping the future of architecture and construction.

At Weifang Sandong Building Materials Co., Ltd., we're proud to be at the forefront of this innovative technology. Our insulated thermal wall panels are designed to meet the highest standards of performance and quality, offering unparalleled protection against moisture and other environmental challenges. Whether you're planning a new construction project or looking to upgrade an existing structure, our team is here to help you find the perfect insulated thermal wall panel solution for your needs.

Ready to experience the benefits of insulated thermal wall panels for yourself? Contact us today at info@sdqsc.com to learn more about our products and how they can transform your next building project. Let's work together to create structures that are not just buildings, but enduring testaments to innovation and efficiency.

FAQ

How long do insulated thermal wall panels typically last?

With proper installation and maintenance, insulated thermal wall panels can last 30-50 years or more.

Are insulated thermal wall panels environmentally friendly?

Yes, they contribute to energy efficiency and many are made with recyclable materials.

Can insulated thermal wall panels be used in both residential and commercial buildings?

Absolutely! They're versatile enough for various applications, from homes to large commercial structures.

Do insulated thermal wall panels require special cleaning?

No, regular cleaning with mild soap and water is typically sufficient to maintain their appearance.

References

1. American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE). (2021). ASHRAE Handbook: Fundamentals.

2. U.S. Department of Energy. (2022). Insulation Materials.

3. Building Science Corporation. (2020). Guide to Insulating Sheathing.

4. National Institute of Building Sciences. (2021). Whole Building Design Guide: Building Envelope Design Guide.