Understanding 10 cm Sandwich Panels and Their Thermal Properties

Composition and Structure of 10 cm Sandwich Panels

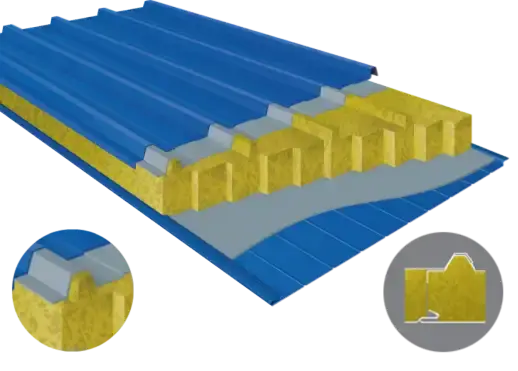

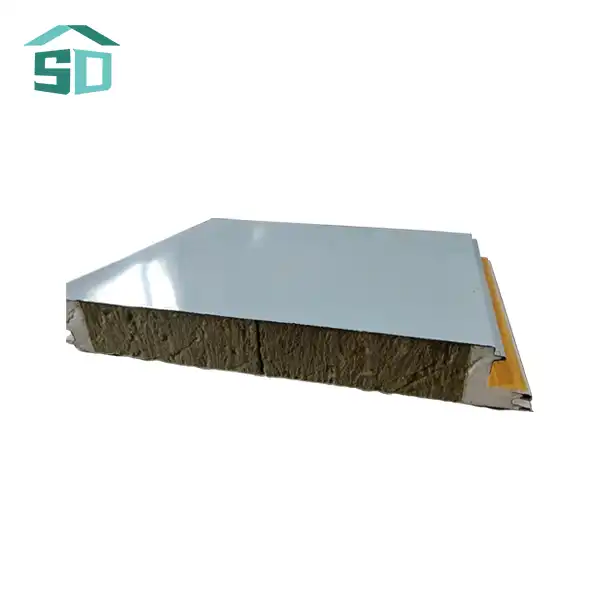

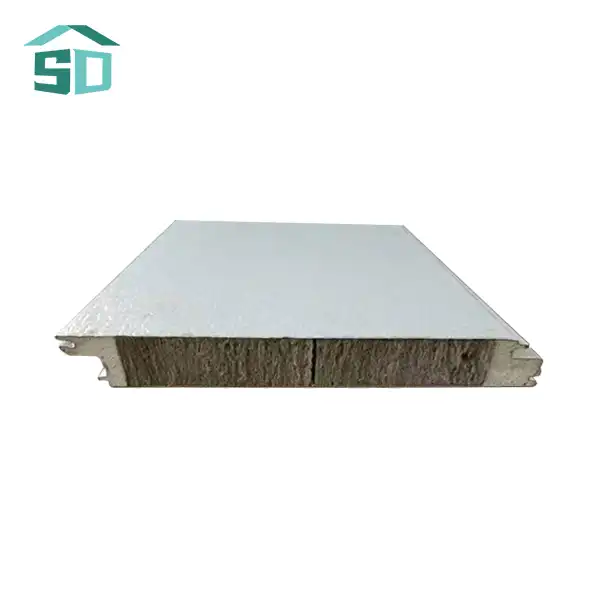

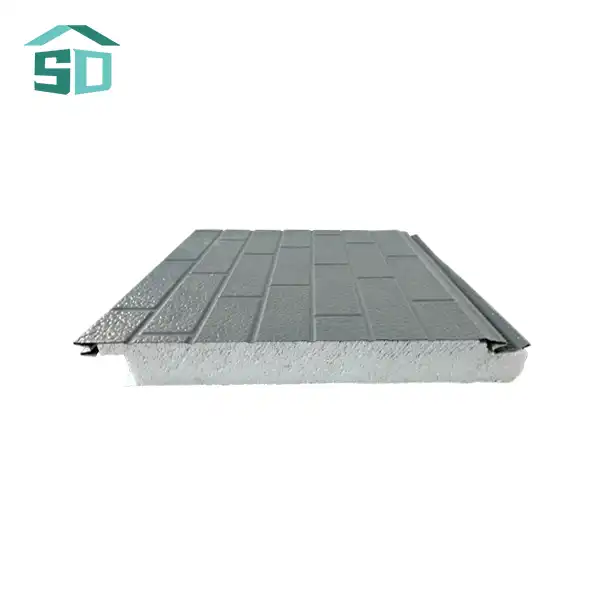

10 cm sandwich panels are meticulously engineered composite structures designed to provide exceptional thermal insulation and structural integrity. These panels consist of three primary components: two outer metal facings and an insulating core. The metal facings, typically made from galvanized steel or aluminum, offer durability and weather resistance. The core, often composed of polyurethane foam, polyisocyanurate, or mineral wool, serves as the primary insulating element.

The thickness of 10 cm sandwich panels is carefully calibrated to optimize thermal performance without compromising on practicality. This specific dimension allows for efficient heat transfer reduction while maintaining a manageable weight and ease of installation. The uniform thickness ensures consistent insulation across the entire panel surface, eliminating potential thermal bridges that could compromise energy efficiency.

Thermal Conductivity and R-Value of 10 cm Sandwich Panels

The thermal conductivity of 10 cm sandwich panels is a crucial factor in their insulation performance. This property, measured in watts per meter-kelvin (W/mK), indicates the panel's ability to resist heat flow. 10 cm sandwich panels typically exhibit low thermal conductivity values, ranging from 0.02 to 0.04 W/mK, depending on the core material used.

The R-value, which quantifies thermal resistance, is another essential metric for assessing the insulation capability of 10 cm sandwich panels. The R-value is directly proportional to the panel thickness and inversely proportional to its thermal conductivity. For 10 cm sandwich panels, R-values can range from R-20 to R-40, depending on the specific composition and manufacturing process. These high R-values translate to superior thermal insulation, making 10 cm sandwich panels an excellent choice for energy-efficient building envelopes.

Comparative Analysis with Other Insulation Materials

When compared to traditional insulation materials, 10 cm sandwich panels offer several advantages. Unlike fiberglass or cellulose insulation, which require separate structural support, 10 cm sandwich panels combine insulation and structural elements in a single unit. This integration simplifies installation and reduces the overall wall thickness required to achieve comparable insulation levels.

Moreover, 10 cm sandwich panels provide consistent insulation performance throughout their lifespan. Unlike loose-fill insulation, which can settle over time and create gaps in coverage, the rigid structure of sandwich panels maintains its insulating properties indefinitely. This consistency ensures long-term energy efficiency and reduces the need for maintenance or reapplication of insulation materials.

Installation Techniques for 10 cm Sandwich Panels

Preparation and Planning for 10 cm Sandwich Panel Installation

Proper preparation is paramount when installing 10 cm sandwich panels for maximum thermal efficiency. Begin by conducting a thorough site assessment, evaluating the existing structure, and identifying any potential obstacles or special considerations. Ensure that the supporting framework is sturdy, level, and capable of bearing the weight of the 10 cm sandwich panels.

Create a detailed installation plan, considering factors such as panel orientation, joint locations, and fastening methods. Pay special attention to areas prone to thermal bridging, such as corners and openings, and devise strategies to maintain continuous insulation at these critical points. Accurate measurements are crucial; use precision tools to determine exact dimensions and account for any necessary cuts or modifications to the 10 cm sandwich panels.

Step-by-Step Guide to Installing 10 cm Sandwich Panels

1. Begin by applying a high-quality vapor barrier to the supporting structure, ensuring a continuous seal to prevent moisture infiltration.

2. Start panel installation from a corner or edge, ensuring the first panel is perfectly level and plumb. Use temporary braces if necessary to maintain alignment.

3. Apply a bead of weatherproof sealant along the panel edges to create an airtight seal between adjacent panels.

4. Carefully position the next 10 cm sandwich panel, aligning it precisely with the first. Use panel lifters or suction cups to maneuver the panels safely.

5. Secure the panels using appropriate fasteners, following the manufacturer's recommendations for spacing and depth. Be cautious not to over-tighten, which could compromise the panel's integrity.

6. Install flashing and trim pieces around openings and at the base of the wall to ensure proper water drainage and further enhance thermal performance.

7. Apply additional sealant to all joints, paying extra attention to corners and intersections to create a continuous thermal barrier.

Tools and Equipment Required for Efficient Installation

To ensure a smooth and efficient installation process for 10 cm sandwich panels, gather the following tools and equipment:

- Panel lifters or suction cups for safe panel handling

- Laser level and plumb bob for precise alignment

- Electric drill with appropriate bits for fastener installation

- Circular saw with metal-cutting blade for panel modifications

- Caulking gun for applying sealants and adhesives

- Tape measure and chalk line for accurate measurements and markings

- Safety equipment including gloves, safety glasses, and hard hats

- Scaffolding or lift equipment for working at heights

- Thermal imaging camera for post-installation inspection of thermal performance

Common Challenges and Solutions in 10 cm Sandwich Panel Installation

While installing 10 cm sandwich panels, installers may encounter several challenges. One common issue is maintaining perfect alignment over large surface areas. To address this, use a laser level and establish reference lines at regular intervals. Temporary bracing can help maintain panel position until fasteners are fully secured.

Another challenge is managing thermal expansion and contraction. 10 cm sandwich panels, particularly those with metal facings, can expand and contract with temperature fluctuations. To mitigate this, ensure proper expansion joints are incorporated into the design and use flexible sealants that can accommodate movement without compromising the thermal seal.

Cutting and modifying 10 cm sandwich panels on-site can also present difficulties. To achieve clean, precise cuts, use specialized cutting tools designed for composite panels. When cutting is necessary, always seal exposed edges to prevent moisture ingress and maintain the panel's insulating properties.

Maximizing Energy Efficiency with 10 cm Sandwich Panels

Optimal Panel Placement for Thermal Performance

To maximize the energy efficiency of 10 cm sandwich panels, strategic placement is crucial. Begin by identifying areas of the building envelope most susceptible to heat loss or gain. Typically, these include north-facing walls in colder climates and south-facing walls in warmer regions. Prioritize the installation of 10 cm sandwich panels in these high-impact areas to achieve the greatest thermal benefit.

Consider the building's orientation and solar exposure when determining panel placement. In areas with intense sunlight, use 10 cm sandwich panels with reflective outer facings to minimize heat absorption. For shaded or northern exposures, panels with darker exteriors may be preferable to absorb and retain heat during colder months.

Pay special attention to thermal weak points such as corners, joints, and intersections between different building elements. Ensure continuous insulation at these critical junctions by using specialized corner panels or custom-cut 10 cm sandwich panels to maintain an unbroken thermal barrier.

Integrating 10 cm Sandwich Panels with Other Building Systems

To achieve maximum thermal efficiency, it's essential to consider how 10 cm sandwich panels interact with other building systems. Coordinate with HVAC professionals to ensure that heating and cooling systems are properly sized to account for the improved insulation provided by the panels. This integration can lead to significant energy savings and improved overall building performance.

When incorporating windows and doors, use thermally broken frames and high-performance glazing to complement the insulation properties of the 10 cm sandwich panels. Carefully detail the transitions between panels and openings to minimize thermal bridging and maintain the integrity of the building envelope.

Consider integrating renewable energy systems, such as solar panels, with the 10 cm sandwich panel installation. Some manufacturers offer panels with pre-engineered mounting points for photovoltaic systems, allowing for seamless integration of energy production and thermal insulation.

Monitoring and Maintaining Thermal Efficiency Over Time

To ensure that 10 cm sandwich panels continue to provide maximum thermal efficiency throughout their lifespan, implement a comprehensive monitoring and maintenance program. Regularly inspect panels for signs of damage, such as dents, scratches, or separation at joints, which could compromise their insulating properties.

Utilize thermal imaging technology to conduct periodic assessments of the building envelope. These scans can identify areas of heat loss or unexpected thermal bridging, allowing for targeted maintenance or additional insulation measures.

Keep panel surfaces clean and free from debris, as accumulated dirt or organic matter can affect the reflective properties of the outer facings and potentially degrade insulation performance over time. Use gentle cleaning methods recommended by the 10 cm sandwich panel manufacturer to avoid damaging the panel surface.

Monitor indoor temperature and humidity levels to ensure that the improved thermal envelope created by the 10 cm sandwich panels is functioning as intended. Adjust HVAC settings as necessary to optimize energy consumption and maintain a comfortable indoor environment.

Case Studies: Successful Implementations of 10 cm Sandwich Panels

Numerous projects across various sectors have successfully implemented 10 cm sandwich panels to achieve remarkable improvements in thermal efficiency. For instance, a large-scale industrial facility in a cold climate region reported a 40% reduction in heating costs after retrofitting its exterior walls with 10 cm sandwich panels. The uniform insulation provided by the panels eliminated thermal bridging issues that had plagued the previous insulation system.

In the commercial sector, a multi-story office building in a hot, arid climate utilized 10 cm sandwich panels with specialized reflective coatings. This implementation resulted in a 35% decrease in cooling energy consumption and significantly improved occupant comfort. The building's sleek, modern appearance, achieved through the use of aesthetically pleasing panel finishes, also enhanced its market value.

A residential development project featuring high-end, energy-efficient homes incorporated 10 cm sandwich panels throughout the building envelopes. Homeowners reported consistently comfortable indoor temperatures and notably lower utility bills compared to similar properties in the area. The rapid installation of the panels also allowed for faster project completion, reducing overall construction costs.

Conclusion

Installing 10 cm panels for maximum thermal efficiency is a proven strategy for enhancing building performance and reducing energy consumption. The unique composition and structure of 10 cm sandwich panels offer superior insulation properties, making them an ideal choice for a wide range of construction projects. By understanding the thermal characteristics of these panels and implementing proper installation techniques, builders and property owners can achieve significant improvements in energy efficiency and indoor comfort. The integration of 10 cm sandwich panels with other building systems, coupled with ongoing monitoring and maintenance, ensures long-term performance and sustainability.

If you're considering using 10 cm sandwich panels for your next construction project or want to explore how these innovative materials can improve your building's thermal efficiency, we invite you to contact Weifang Sandong Building Materials Co., Ltd. Our team of experts can provide detailed information about our 10 cm sandwich panel offerings and help you determine the best solution for your specific needs. Reach out to us at info@sdqsc.com to learn more about our products and how they can contribute to your project's success.

FAQs

What makes 10 cm sandwich panels different from other insulation materials?

10 cm sandwich panels combine structural support and insulation in one unit, offering consistent performance and minimizing thermal bridging.

How long do 10 cm sandwich panels typically last?

With proper installation and maintenance, 10 cm sandwich panels can last 30-50 years or more.

Can 10 cm sandwich panels be used in both residential and commercial buildings?

Yes, these panels are versatile and suitable for various construction types, including homes, offices, and industrial facilities.

Are 10 cm sandwich panels environmentally friendly?

Many 10 cm sandwich panels are made with recyclable materials and contribute to energy efficiency, supporting sustainable building practices.

How do I choose the right 10 cm sandwich panel for my project?

Consider factors such as climate, building type, and local regulations. Consult with experts like those at Weifang Sandong Building Materials Co., Ltd. for personalized advice.

References

1. American Society of Heating, Refrigerating and Air-Conditioning Engineers. (2017). ASHRAE Handbook: Fundamentals. ASHRAE.

2. Oral, G. K., Yilmaz, Z., & Mankibi, M. (2019). Building envelope design with the objective to ensure thermal, visual and acoustic comfort conditions. Building and Environment, 156, 250-260.

3. Sadineni, S. B., Madala, S., & Boehm, R. F. (2011). Passive building energy savings: A review of building envelope components. Renewable and Sustainable Energy Reviews, 15(8), 3617-3631.

4. Schiavoni, S., D׳Alessandro, F., Bianchi, F., & Asdrubali, F. (2016). Insulation materials for the building sector: A review and comparative analysis. Renewable and Sustainable Energy Reviews, 62, 988-1011.

5. U.S. Department of Energy. (2015). Insulation Materials. Energy Saver.