Understanding PUF Sandwich Panels: A Revolution in Building Materials

The Composition and Structure of PUF Sandwich Panels

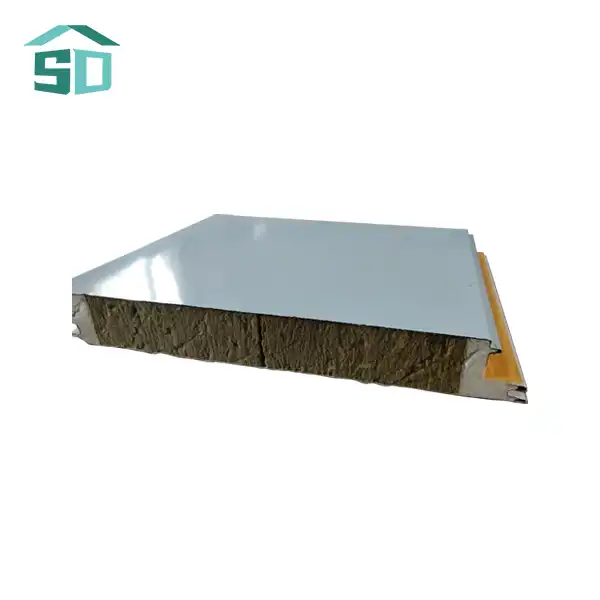

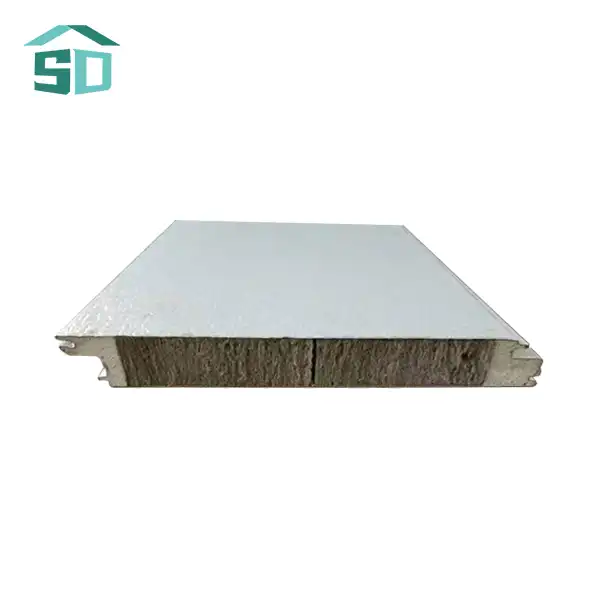

PUF sandwich panels are a marvel of modern engineering. At their core lies a layer of polyurethane foam, renowned for its exceptional insulation properties. This core is encased between two layers of metal, typically steel or aluminum, creating a robust and versatile building material. The unique composition of PUF sandwich panels allows them to offer a perfect balance of strength, lightness, and insulation.

The foam core of PUF sandwich panels is the secret behind their impressive thermal performance. This layer acts as a formidable barrier against heat transfer, significantly reducing energy costs associated with heating and cooling. Moreover, the metal outer layers provide durability and weather resistance, ensuring the panels can withstand various environmental challenges.

The Manufacturing Process: Ensuring Quality and Consistency

The production of PUF sandwich panels is a meticulous process that demands precision and quality control at every step. Leading PUF sandwich panel manufacturers, like Weifang Sandong Building Materials Co., Ltd., employ state-of-the-art production lines and rigorous quality control systems. These systems include comprehensive inspections of raw materials such as steel coils, aluminum foil, and polyurethane.

During manufacturing, each panel undergoes strict testing for thickness, paint film consistency, mechanical strength, and flame retardancy. This ensures that every PUF sandwich panel meets the highest standards of quality and performance. The result is a building material that contractors and architects can rely on for consistent excellence across a wide range of applications.

Versatility in Design and Application

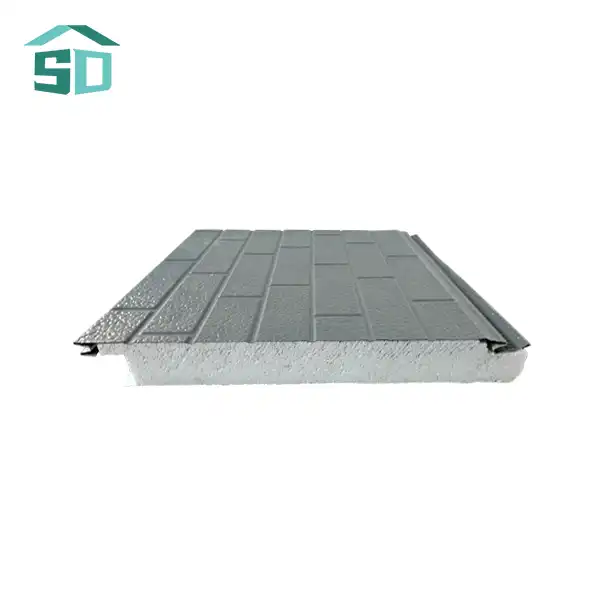

One of the most compelling aspects of PUF sandwich panels is their versatility. These panels can be customized in terms of size, thickness, and color, making them suitable for a vast array of architectural styles and building requirements. From sleek, modern office buildings to cozy residential homes, PUF sandwich panels can be adapted to suit any aesthetic vision.

The application of PUF sandwich panels extends far beyond traditional construction. They are increasingly used in innovative ways, including:

- Modular construction projects

- Cold storage facilities

- Agricultural buildings

- Industrial warehouses

- Clean rooms in pharmaceutical and technology sectors

This adaptability makes PUF sandwich panels a favorite among architects and builders who value flexibility in their design approach.

The Installation Advantage: Speed and Efficiency with PUF Sandwich Panels

Streamlined Installation Process

The installation of PUF sandwich panels is where their true efficiency shines. Unlike traditional building materials that often require multiple steps and components, PUF sandwich panels offer a streamlined installation process. This simplification leads to significant time savings on construction sites, reducing labor costs and accelerating project timelines.

The installation process typically involves the following steps:

- Preparation of the structural frame

- Measuring and cutting panels to size (if necessary)

- Securing panels to the frame using specialized fasteners

- Sealing joints and edges for optimal insulation and weather resistance

This straightforward process allows even complex structures to be erected in a fraction of the time required for conventional building methods.

Reduced Labor Requirements and Costs

The ease of installation of PUF sandwich panels translates directly into reduced labor requirements. Fewer workers are needed on site, and the skills required for installation are less specialized compared to traditional construction methods. This not only reduces direct labor costs but also minimizes the potential for delays due to labor shortages or scheduling conflicts.

Moreover, the lightweight nature of PUF sandwich panels means that heavy machinery is often unnecessary for their installation. This further reduces equipment rental costs and site preparation requirements, contributing to overall project cost savings.

Minimized On-Site Waste and Environmental Impact

PUF sandwich panels are typically manufactured to precise specifications, reducing the need for on-site cutting and modifications. This precision manufacturing results in minimal waste generated during the installation process. Any waste that is produced is often recyclable, aligning with modern sustainability goals in construction.

The reduced need for multiple materials and fewer vehicle trips to the construction site (due to the all-in-one nature of PUF sandwich panels) also contributes to a lower environmental impact. This makes PUF sandwich panels an attractive option for projects aiming for green building certifications or seeking to minimize their carbon footprint.

Long-Term Benefits: Durability and Performance of PUF Sandwich Panels

Superior Insulation and Energy Efficiency

The insulation properties of PUF sandwich panels are truly exceptional. The polyurethane foam core provides an impressive R-value, significantly outperforming many traditional insulation materials. This superior insulation translates into tangible benefits for building owners and occupants:

- Reduced heating and cooling costs

- Improved indoor comfort

- Minimized thermal bridging

- Enhanced sound insulation

These energy-efficient characteristics make PUF sandwich panels an ideal choice for both new construction and retrofit projects aiming to improve building performance and reduce operational costs.

Weather Resistance and Longevity

PUF sandwich panels are engineered to withstand harsh environmental conditions. The metal outer layers provide excellent protection against UV radiation, wind, rain, and snow. This durability ensures that buildings constructed with PUF sandwich panels maintain their structural integrity and appearance over time, reducing the need for frequent repairs or replacements.

Furthermore, the closed-cell structure of the polyurethane foam core prevents moisture absorption, mitigating the risk of mold growth and internal damage. This resistance to moisture intrusion is particularly valuable in humid climates or applications where water exposure is a concern.

Fire Safety and Building Code Compliance

Safety is paramount in construction, and PUF sandwich panels are designed with this in mind. Many PUF sandwich panels are manufactured to meet stringent fire safety standards, often achieving a B1 fire protection level. This fire resistance is crucial for ensuring occupant safety and complying with building codes across various jurisdictions.

The fire-resistant properties of PUF sandwich panels are achieved through careful material selection and manufacturing processes. Some panels incorporate fire-retardant additives in the foam core, while others feature specially designed facings that enhance fire performance. This attention to safety makes PUF sandwich panels suitable for a wide range of building types, including those with strict fire code requirements.

Conclusion

PUF sandwich panels represent a significant leap forward in building technology, offering a unique combination of durability, efficiency, and performance. Their rapid installation process, coupled with long-term benefits in energy efficiency and structural integrity, makes them an invaluable asset in modern construction. As the industry continues to evolve, PUF sandwich panels stand out as a solution that meets the demands of today's fast-paced, sustainability-focused construction landscape.

Are you ready to experience the transformative benefits of PUF sandwich panels in your next construction project? Weifang Sandong Building Materials Co., Ltd. offers a wide range of high-quality PUF sandwich panels tailored to your specific needs. From customizable designs to expert installation advice, we're here to help you maximize the potential of this innovative building material. Contact us today at info@sdqsc.com to learn more about how our PUF sandwich panels can revolutionize your construction process and deliver lasting value to your projects.

FAQ

What are the main advantages of using PUF sandwich panels in construction?

PUF sandwich panels offer excellent insulation, quick installation, durability, and versatility in design. They significantly reduce energy costs, construction time, and labor requirements while providing superior weather resistance and fire safety.

How do PUF sandwich panels compare to traditional building materials in terms of installation time?

PUF sandwich panels typically install much faster than traditional materials due to their all-in-one design and lightweight nature, often reducing construction timelines by up to 50%.

Are PUF sandwich panels suitable for both new construction and renovation projects?

Yes, PUF sandwich panels are highly adaptable and can be used effectively in both new builds and renovations across a wide range of building types, from residential to industrial applications.

References

1. Building Science Corporation. (2020). "Guide to Insulating Sheathing."

2. International Code Council. (2021). "International Building Code."

3. U.S. Department of Energy. (2022). "Insulation Materials."

4. American Society of Heating, Refrigerating and Air-Conditioning Engineers. (2021). "ASHRAE Handbook - Fundamentals." Atlanta, GA: ASHRAE.

5. National Institute of Building Sciences. (2022). "Whole Building Design Guide."