Comprehending Aluminum Foam Sandwich Panels

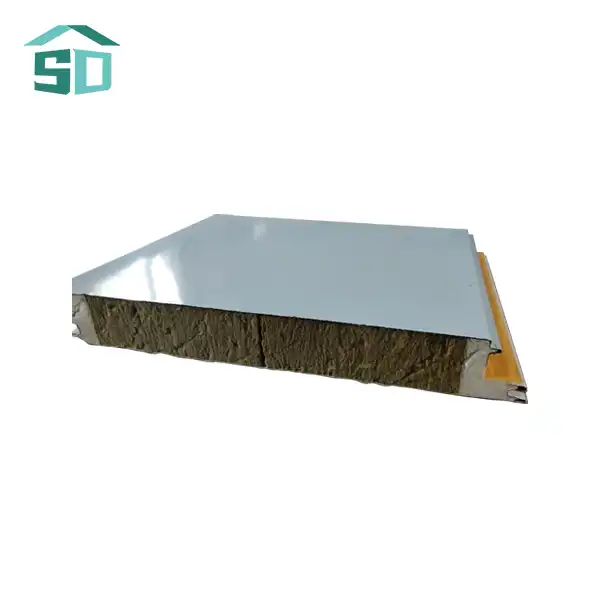

Aluminum foam sandwich panels are a cutting-edge composite material that combines the strength of aluminum with the lightweight properties of foam. These panels consist of two dense aluminum face sheets bonded to a core made of aluminum foam. The result is a material that boasts an exceptional strength-to-weight ratio and remarkable energy absorption capabilities.

The Structure of Aluminum Foam Sandwich Panels

The unique structure of aluminum foam sandwich panels is what gives them their extraordinary properties. The aluminum foam core is created through a process that introduces gas bubbles into molten aluminum, resulting in a cellular structure that resembles a sponge. This foam is then sandwiched between two solid aluminum sheets, creating a panel that combines the best properties of both materials.

Aluminum foam sandwich panel manufacturers have perfected this process to create panels with consistent density and cell size throughout the core. This uniformity ensures that the panels perform reliably under various conditions, making them ideal for demanding applications in industries such as aerospace, automotive, and construction.

Advantages of Aluminum Foam Sandwich Panels

The benefits of aluminum foam sandwich panels are numerous, making them an attractive option for a wide range of applications:

- Lightweight yet strong: The foam core significantly reduces weight without compromising structural integrity.

- Excellent energy absorption: Ideal for impact protection and noise reduction.

- High thermal insulation: The foam structure provides superior insulation properties.

- Fire resistance: Aluminum foam can be engineered to meet stringent fire safety standards.

- Corrosion resistance: The aluminum face sheets offer protection against environmental factors.

- Customizable: Panels can be tailored to specific strength and weight requirements.

Applications of Aluminum Foam Sandwich Panels

The versatility of aluminum foam sandwich panels has led to their adoption in various industries:

- Aerospace: Used in aircraft interiors and structural components.

- Automotive: Applied in crash-absorbing structures and lightweight body panels.

- Marine: Utilized in ship hulls and decking for weight reduction and improved performance.

- Construction: Employed as exterior wall cladding and roofing material for energy-efficient buildings.

- Industrial: Incorporated into machinery for vibration damping and thermal management.

Exploring Honeycomb Panels

Honeycomb panels, named for their resemblance to a bee's honeycomb, are another type of sandwich panel that offers unique benefits. These panels consist of a core made of hexagonal cells, typically constructed from aluminum or other materials, sandwiched between two thin face sheets.

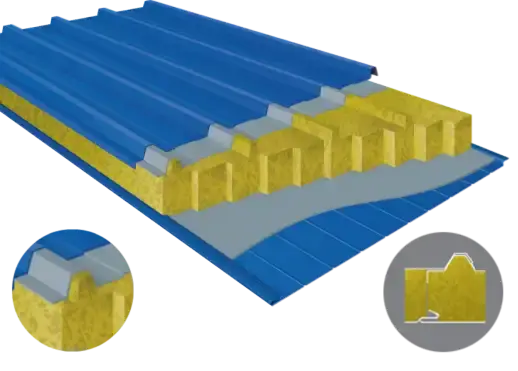

The Structure of Honeycomb Panels

The honeycomb core is the defining feature of these panels. The hexagonal cell structure provides exceptional strength and stiffness while maintaining a low weight. The face sheets, which can be made from various materials including aluminum, fiberglass, or carbon fiber, are bonded to the core to create a rigid panel.

While not directly related to aluminum foam sandwich panels, it's worth noting that some manufacturers have explored combining honeycomb structures with foam materials to create hybrid panels that offer the benefits of both technologies.

Advantages of Honeycomb Panels

Honeycomb panels offer several advantages that make them attractive for certain applications:

- Extremely lightweight: The hollow core structure results in panels with very low density.

- High strength-to-weight ratio: Ideal for applications where weight savings are critical.

- Excellent flatness: The regular cell structure ensures a smooth, flat surface.

- Flexibility in design: Core and face sheet materials can be varied to meet specific requirements.

- Good acoustic properties: The cellular structure can help with sound absorption.

- Thermal insulation: Depending on the core material, can provide effective insulation.

Applications of Honeycomb Panels

Honeycomb panels find use in a variety of industries:

- Aerospace: Used extensively in aircraft interiors and structural components.

- Architecture: Applied in decorative panels and lightweight doors.

- Furniture: Utilized in lightweight, durable tabletops and cabinet doors.

- Transportation: Incorporated into high-speed train interiors and truck bodies.

- Marine: Used in boat hulls and decking for weight reduction.

Comparing Aluminum Foam and Honeycomb Panels

When choosing between aluminum foam sandwich panels and honeycomb panels, several factors come into play. Each material has its strengths, and the best choice depends on the specific requirements of your project.

Strength and Weight Considerations

Both aluminum foam sandwich panels and honeycomb panels offer excellent strength-to-weight ratios, but they achieve this in different ways. Aluminum foam panels provide a more uniform distribution of strength throughout the panel, while honeycomb panels concentrate strength along the axis of the cells. For applications requiring multi-directional strength, aluminum foam sandwich panels may have an edge.

Energy Absorption and Impact Resistance

In terms of energy absorption, aluminum foam sandwich panels generally outperform honeycomb panels. The foam structure allows for controlled deformation under impact, making these panels excellent for crash protection and blast resistance. Honeycomb panels, while still offering good impact resistance, tend to have a more abrupt failure mode.

Thermal and Acoustic Properties

Both panel types offer good thermal insulation, but aluminum foam sandwich panels often have the upper hand due to the closed-cell nature of the foam. This structure also contributes to better sound dampening properties in aluminum foam panels compared to honeycomb structures, which can sometimes act as resonance chambers.

Customization and Manufacturing

Honeycomb panels offer more flexibility in terms of core and face sheet material combinations, allowing for a wider range of properties. However, aluminum foam sandwich panel manufacturers have made significant strides in customizing foam density and cell size to meet specific requirements. The manufacturing process for aluminum foam panels is generally more complex, which can impact cost and production times.

Cost Considerations

The cost of these panels can vary significantly based on the specific materials and manufacturing processes used. Generally, honeycomb panels tend to be less expensive due to simpler manufacturing processes. However, the unique properties of aluminum foam sandwich panels can justify their higher cost in applications where their specific benefits are crucial.

Conclusion

The choice between aluminum foam sandwich panels and honeycomb panels ultimately depends on the specific requirements of your project. Aluminum foam panels excel in applications requiring high energy absorption, multi-directional strength, and superior thermal and acoustic insulation. Honeycomb panels shine in situations where extreme lightweight properties and cost-effectiveness are paramount. Both materials represent significant advancements in composite technology, offering innovative solutions for various industries.

At Weifang Sandong Building Materials Co., Ltd., we understand the importance of choosing the right material for your project. Our expertise in exterior cladding and facade solutions, including advanced aluminum foam sandwich panels, allows us to provide tailored advice and products to meet your specific needs. Whether you're looking for durability, energy efficiency, or aesthetic appeal, our range of exterior wall cladding panels offers the perfect solution. For more information on how our products can enhance your construction project, don't hesitate to contact us at info@sdqsc.com.

FAQ

Are aluminum foam sandwich panels suitable for exterior wall cladding?

Yes, aluminum foam sandwich panels are excellent for exterior wall cladding due to their thermal insulation, fire resistance, and customizable aesthetics.

How do honeycomb panels compare to aluminum foam panels in terms of weight?

Honeycomb panels are generally lighter than aluminum foam panels, but the exact weight difference depends on the specific designs and materials used.

Can aluminum foam sandwich panels be recycled?

Yes, aluminum foam sandwich panels are recyclable, making them an environmentally friendly option for construction projects.

References

1. Banhart, J. (2001). Manufacture, characterisation and application of cellular metals and metal foams. Progress in Materials Science, 46(6), 559-632.

2. Ashby, M. F., Evans, A., Fleck, N. A., Gibson, L. J., Hutchinson, J. W., & Wadley, H. N. G. (2000). Metal Foams: A Design Guide. Butterworth-Heinemann.

3. Bitzer, T. (1997). Honeycomb Technology: Materials, Design, Manufacturing, Applications and Testing. Springer Science & Business Media.

4. Wadley, H. N. G. (2006). Multifunctional periodic cellular metals. Philosophical Transactions of the Royal Society A: Mathematical, Physical and Engineering Sciences, 364(1838), 31-68.