Vinyl Panels: The Low-Maintenance Marvel

Effortless Upkeep of Vinyl Waterproof Exterior Wall Panels

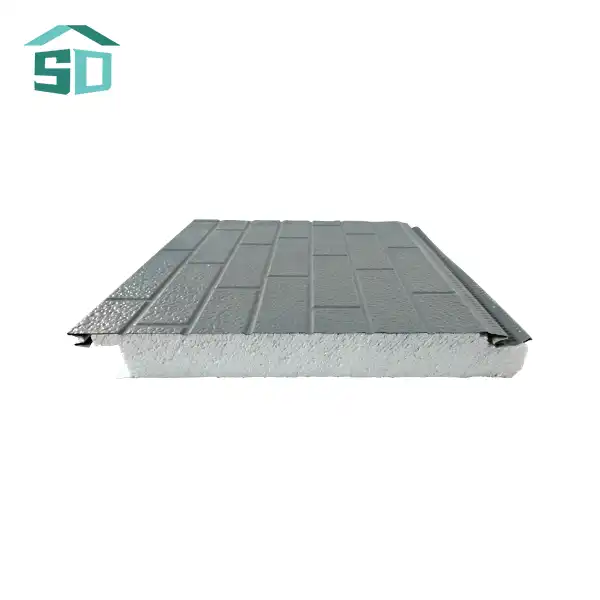

Vinyl panels have gained immense popularity in the construction industry, particularly as waterproof exterior wall panels. Their appeal lies largely in their minimal maintenance requirements. Unlike some traditional materials, vinyl doesn't rot, warp, or corrode, making it an ideal choice for areas exposed to harsh weather conditions.

The maintenance routine for vinyl panels is refreshingly simple. A yearly wash with a mild detergent and water solution is usually sufficient to keep these panels looking fresh and vibrant. This can be done using a soft-bristled brush or a pressure washer on a low setting. It's important to note that while vinyl is resistant to most stains, any stubborn marks should be addressed promptly to prevent long-term discoloration.

One of the standout features of vinyl waterproof exterior wall panels is their color retention. Unlike wood or fiber cement, which may require periodic repainting, vinyl panels maintain their color for years, even when exposed to intense sunlight. This characteristic not only reduces maintenance costs but also ensures that your building's exterior remains aesthetically pleasing for longer periods.

Long-Term Durability and Cost-Effectiveness

When considering the long-term maintenance of waterproof exterior wall panels, vinyl presents a compelling case. Its durability translates to fewer replacements over time, which can significantly reduce overall maintenance costs. While the initial investment in high-quality vinyl panels might be higher, the reduced need for repairs, repainting, or replacement often results in lower lifetime costs compared to some alternatives.

Moreover, vinyl panels are engineered to withstand extreme weather conditions. They resist impact from hail and strong winds, and they don't absorb moisture, which prevents issues like swelling or warping. This resilience means that even in challenging climates, vinyl panels maintain their integrity and appearance with minimal intervention.

It's worth noting that while vinyl panels are low-maintenance, they're not entirely maintenance-free. Regular inspections are still recommended to catch any potential issues early. This might include checking for loose panels or ensuring that the caulking around windows and doors remains intact to maintain the waterproof barrier.

Fiber Cement Panels: Durable Yet Demanding

Comprehensive Care for Fiber Cement Waterproof Exterior Wall Panels

Fiber cement panels, another popular choice for waterproof exterior wall panels, offer a different maintenance profile compared to vinyl. These panels, composed of cement, sand, and cellulose fibers, provide exceptional durability and a natural appearance that many property owners find appealing. However, their maintenance requirements are more involved than those of vinyl panels.

The primary maintenance task for fiber cement panels is periodic repainting or re-staining. Depending on the climate and the quality of the initial finish, this might be necessary every 7-15 years. The repainting process involves thorough cleaning, priming, and applying a high-quality exterior paint. This not only refreshes the appearance but also renews the protective layer that shields the panels from moisture and UV damage.

Regular cleaning is also crucial for fiber cement waterproof exterior wall panels. While they don't require annual washing like vinyl, it's recommended to clean them every 6-12 months to prevent the buildup of dirt and grime. This can typically be accomplished with a garden hose and a soft brush, avoiding high-pressure washing which could damage the surface.

Addressing Unique Challenges of Fiber Cement

Fiber cement panels, while robust, can be susceptible to certain issues that require attention. One such concern is the potential for cracks or chips. Unlike vinyl, which is flexible, fiber cement is rigid and can crack if subjected to significant impact. Any damage should be promptly repaired to prevent moisture ingress, which could compromise the panel's integrity and waterproof properties.

Another aspect of maintenance unique to fiber cement waterproof exterior wall panels is the need to monitor and maintain the caulking around joints and seams. Over time, this caulking can deteriorate, potentially allowing water to penetrate behind the panels. Regular inspection and re-caulking as needed are essential to maintain the waterproof barrier.

It's also worth noting that fiber cement panels can be more challenging to replace if damaged. While individual vinyl panels can often be easily swapped out, replacing a fiber cement panel might require more extensive work. This underscores the importance of proper installation and ongoing maintenance to avoid the need for replacements.

Comparative Analysis: Making the Right Choice

Balancing Aesthetics and Practicality in Waterproof Exterior Wall Panels

When deciding between vinyl and fiber cement waterproof exterior wall panels, it's crucial to weigh the maintenance requirements against other factors such as aesthetics, durability, and cost. Vinyl panels offer unparalleled ease of maintenance, making them an attractive option for those seeking a low-effort solution. Their resistance to fading and ability to withstand harsh weather conditions without significant degradation means that they can maintain their appearance for many years with minimal intervention.

Fiber cement panels, while requiring more maintenance, offer a distinct aesthetic that many find appealing. They can mimic the look of wood or stone more convincingly than vinyl, which may be a deciding factor for some property owners. The ability to repaint fiber cement panels also allows for more flexibility in changing the exterior appearance of a building over time, something that's not as easily achieved with vinyl.

From a durability standpoint, both materials perform admirably as waterproof exterior wall panels. Fiber cement's resistance to fire and pests gives it an edge in certain applications, while vinyl's flexibility makes it more resistant to impact damage. The choice often comes down to specific environmental conditions and personal preferences.

Long-Term Considerations for Waterproof Exterior Wall Panels Factory Selection

When sourcing from a waterproof exterior wall panels factory, it's important to consider not just the initial costs but also the long-term maintenance requirements. A reputable manufacturer should provide detailed maintenance guidelines for their products, helping property owners make an informed decision.

For vinyl panels, inquire about the thickness of the material and the quality of the color infusion process. Higher quality vinyl panels may cost more initially but can offer superior longevity and color retention, reducing long-term maintenance needs.

For fiber cement panels, ask about the factory-applied finishes available. Some manufacturers offer pre-painted or pre-stained options with warranties covering the finish for several years. This can significantly reduce the frequency of repainting required, altering the maintenance equation in favor of fiber cement.

Ultimately, the choice between vinyl and fiber cement waterproof exterior wall panels should be based on a careful consideration of maintenance requirements, aesthetic preferences, climate conditions, and long-term cost projections. By thoroughly understanding these factors, property owners can make an informed decision that balances beauty, practicality, and long-term value.

Conclusion

In conclusion, the maintenance requirements for vinyl and fiber cement waterproof exterior wall panels differ significantly. Vinyl offers a low-maintenance solution with excellent durability and color retention, requiring only simple cleaning to maintain its appearance. Fiber cement, while more demanding in terms of upkeep, provides a natural aesthetic and the flexibility to change colors over time. Both materials have their strengths, and the choice ultimately depends on specific project needs, environmental conditions, and personal preferences.

At Weifang Sandong Building Materials Co., Ltd., we understand the importance of choosing the right waterproof exterior wall panels for your project. Our range of high-quality, customizable panels combines durability with aesthetic appeal, offering solutions that meet diverse architectural needs while minimizing maintenance requirements. Whether you're looking for the ease of vinyl or the classic look of fiber cement, we have options to suit your specific requirements. For expert advice on selecting the perfect waterproof exterior wall panels for your next project, don't hesitate to reach out to us at info@sdqsc.com.

FAQs

How often should I clean my waterproof exterior wall panels?

For vinyl panels, an annual wash is typically sufficient. Fiber cement panels may require cleaning every 6-12 months.

Can I repaint vinyl waterproof exterior wall panels?

While possible, it's not recommended as vinyl is designed to retain its color. Repainting may void warranties and is generally unnecessary.

How long do fiber cement panels typically last before needing repainting?

Depending on climate and exposure, fiber cement panels usually require repainting every 7-15 years.

Are waterproof exterior wall panels suitable for all climates?

Yes, but the choice between vinyl and fiber cement may depend on specific climate conditions. Consult with our experts at info@sdqsc.com for tailored advice.

Can damaged panels be easily replaced?

Vinyl panels are generally easier to replace individually. Fiber cement panel replacement might require more extensive work.

References

1.National Association of Home Builders. (2021). "Exterior Siding Materials: A Guide for Homeowners."

2.Journal of Building Engineering. (2020). "Comparative Study on Durability of Exterior Cladding Materials."

3.American Society for Testing and Materials. (2022). "Standard Guide for Design of Exterior Wall Systems."

4.Building Science Corporation. (2019). "Moisture Control for Building Envelopes."

5.U.S. Department of Energy. (2021). "Guide to Weatherization Materials for Homes."