- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Innovations in Fireproof Sandwich Panels

In the ever-evolving world of construction materials, PU insulated sandwich panels have emerged as a game-changer. These innovative panels are revolutionizing the way we approach building insulation, fire safety, and energy efficiency. As a leading PU insulated sandwich panels factory, Weifang Sandong Building Materials Co., Ltd. is at the forefront of this transformation, pushing the boundaries of what's possible in construction technology.

The Evolution of Fireproof Sandwich Panels

Understanding the Basics of PU Insulated Sandwich Panels

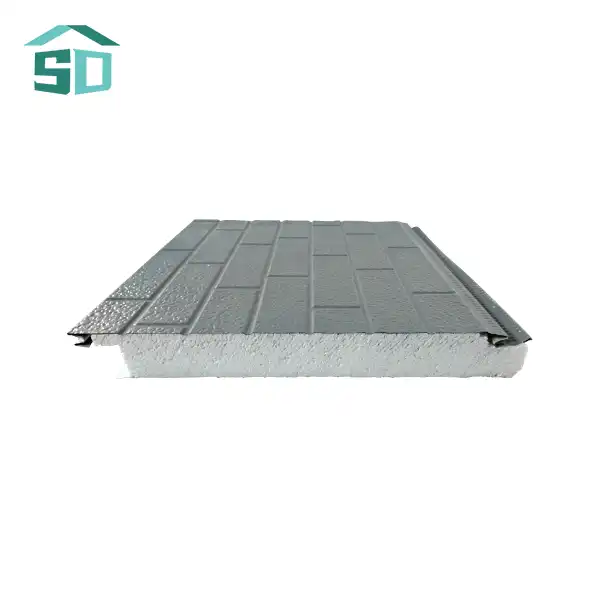

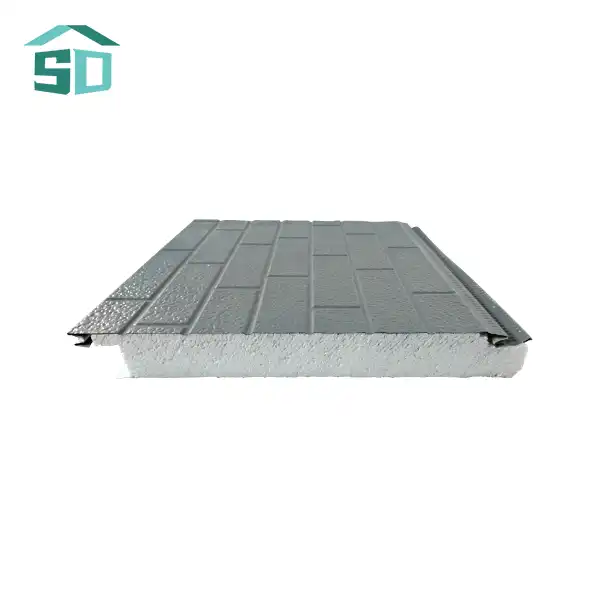

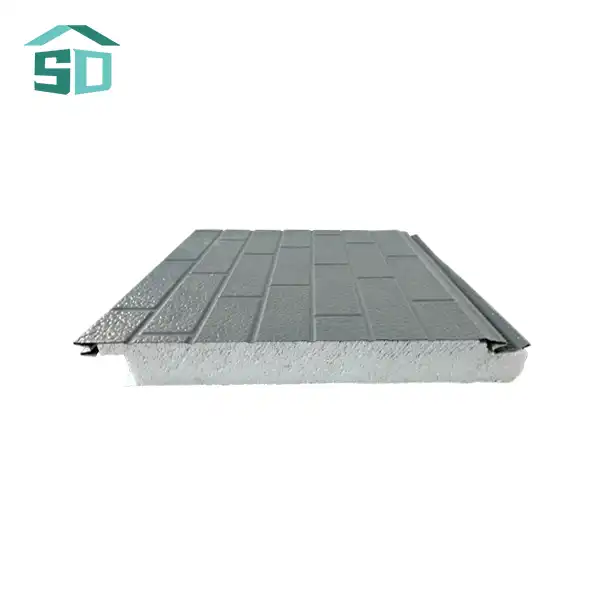

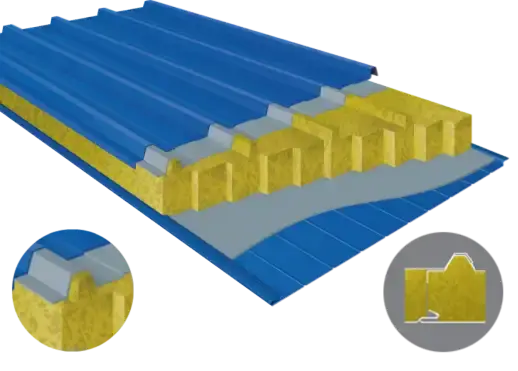

PU insulated sandwich panels are advanced composite materials composed of two durable metal facings—typically steel or aluminum—encasing a core of polyurethane foam. This carefully engineered structure delivers outstanding thermal insulation, excellent structural integrity, and superior fire resistance. By minimizing heat conduction, radiation, and convection, these panels effectively maintain stable indoor temperatures and reduce energy consumption. Their combination of strength, lightweight design, and insulating performance makes them an ideal choice for a wide range of applications, including industrial facilities, commercial buildings, cold storage, and climate-controlled environments.

Advancements in Fire Resistance Technology

Recent innovations have significantly enhanced the fire-resistant properties of PU insulated sandwich panels. Manufacturers like Sandong Building Materials have developed advanced formulations that incorporate fire-retardant additives into the polyurethane core. These additives work to inhibit flame spread and smoke development, meeting stringent fire safety standards without compromising the panels' insulating properties.

The Role of Nanotechnology in Fireproofing

Nanotechnology has opened up new possibilities in the realm of fireproof sandwich panels. By incorporating nanoparticles into the PU foam core, manufacturers can create panels with superior fire resistance and improved structural stability. These nanoparticles act as flame retardants at the molecular level, providing an additional layer of protection against fire hazards.

Innovative Applications of PU Insulated Sandwich Panels

Modular Construction and Prefabrication

PU insulated sandwich panels are increasingly being used in modular and prefabricated construction. Their lightweight nature and excellent insulation properties make them ideal for off-site manufacturing and rapid on-site assembly. This approach not only speeds up construction timelines but also ensures consistent quality and reduced waste.

Green Building and Sustainable Architecture

As the construction industry moves towards more sustainable practices, PU insulated sandwich panels are playing a crucial role. These panels contribute to energy-efficient building envelopes, reducing heating and cooling costs while minimizing the carbon footprint of structures. The longevity and recyclability of these panels further enhance their eco-friendly credentials.

Adaptive Reuse and Retrofitting

Innovative PU insulated sandwich panels are not just for new constructions. They are also proving invaluable in the adaptive reuse of older buildings and retrofitting projects. These panels can be easily installed over existing structures, providing immediate improvements in insulation and fire safety without the need for extensive renovations.

The Future of Fireproof Sandwich Panels

Smart Panels with Integrated Sensors

The next frontier in PU insulated sandwich panel technology lies in the integration of smart sensors directly into the panels. These advanced sensors can continuously monitor environmental conditions such as temperature, humidity, and even detect early signs of fire or structural stress. By providing real-time data to building management systems, this technology allows for proactive maintenance, energy optimization, and improved safety. The combination of IoT connectivity with construction materials has the potential to revolutionize how buildings are managed, enabling intelligent, responsive infrastructure that enhances efficiency, occupant comfort, and overall operational performance.

Biobased and Recyclable Materials

Research is increasingly focused on developing PU insulated sandwich panels made from biobased polyurethane foams derived from renewable resources. These sustainable alternatives aim to reduce the environmental footprint of panel production while still delivering the high thermal, structural, and fire-resistant performance expected from traditional panels. Simultaneously, advancements in recycling technologies are enabling the recovery and reuse of materials from old panels, helping to minimize construction waste. This move toward biobased and recyclable panels supports a circular economy in the construction industry, promoting sustainability without compromising quality or durability.

Enhanced Acoustic Performance

Although thermal insulation and fire resistance have historically been the primary focus of PU insulated sandwich panel development, recent innovations are increasingly targeting acoustic performance. New panel designs incorporate sound-absorbing layers or specialized core materials to reduce noise transmission, making them suitable for noise-sensitive environments such as schools, hospitals, offices, and residential buildings. By combining thermal, fire, and acoustic benefits into a single panel solution, manufacturers can provide more versatile and high-performance products. These advancements improve occupant comfort, meet regulatory standards, and expand the application range of PU insulated sandwich panels in modern construction projects.

Conclusion

The innovations in fireproof sandwich panels, particularly PU insulated sandwich panels, are transforming the construction industry. These advancements are not only enhancing building safety and energy efficiency but also contributing to more sustainable and adaptable architectural solutions. As technology continues to evolve, we can expect even more groundbreaking developments in this field, further solidifying the position of PU insulated sandwich panels as a cornerstone of modern construction.

At Weifang Sandong Building Materials Co., Ltd., we are committed to staying at the cutting edge of these innovations. Our state-of-the-art production lines and rigorous quality control systems ensure that our PU insulated sandwich panels meet the highest standards of performance and safety. Whether you're planning a new construction project or looking to upgrade existing structures, our expert team is ready to provide you with tailored solutions that meet your specific needs. Contact us at info@sdqsc.com to learn more about how our innovative PU insulated sandwich panels can benefit your next project.

FAQs

What makes PU insulated sandwich panels fireproof?

PU insulated sandwich panels achieve fire resistance through specially formulated polyurethane cores with fire-retardant additives and advanced manufacturing techniques.

How do these panels contribute to energy efficiency?

The panels provide excellent thermal insulation, reducing heat transfer and lowering heating and cooling costs in buildings.

Are PU insulated sandwich panels environmentally friendly?

Yes, they contribute to sustainable construction by improving energy efficiency and being potentially recyclable at the end of their lifecycle.

Can these panels be used in residential construction?

Absolutely. PU insulated sandwich panels are versatile and suitable for various applications, including residential buildings.

How long do PU insulated sandwich panels typically last?

With proper installation and maintenance, these panels can last for several decades, providing long-term value and performance.

References

1. Wang, Y., et al. (2020). "Recent advances in fire retardant polyurethane foam." Journal of Materials Science, 55(17), 7341-7365.

2. Zhuang, X., et al. (2021). "Nanotechnology in construction materials: Recent advances and future perspectives." Construction and Building Materials, 297, 123768.

3. Berardi, U., & Manca, M. (2017). "The energy saving and indoor comfort improvements with latent thermal energy storage in building envelopes." Energy and Buildings, 150, 479-489.

4. Ismail, M., et al. (2019). "Prefabricated building using sandwich panels: A review." Journal of Building Engineering, 25, 100790.

5. Sandberg, L. I. C., & Holt, T. (2018). "Life cycle assessment of sandwich panels." Energy Procedia, 153, 426-431.