The Science Behind Metal Insulated Sandwich Panels

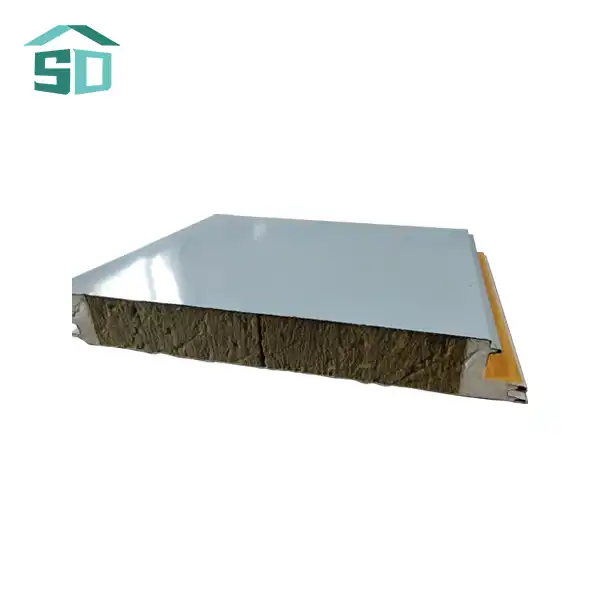

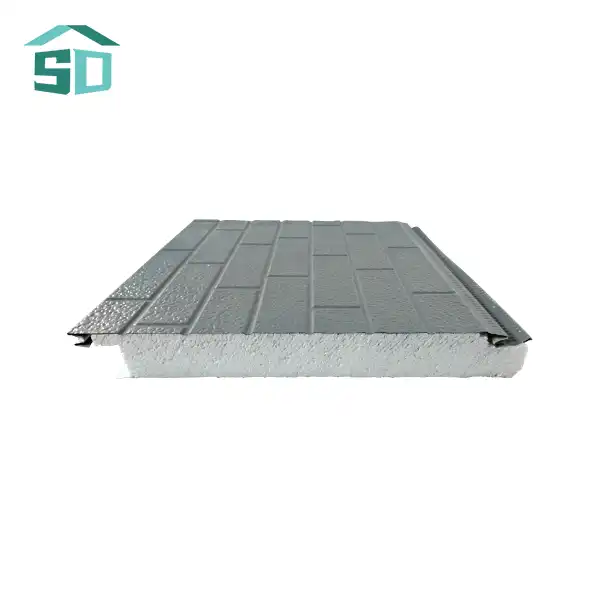

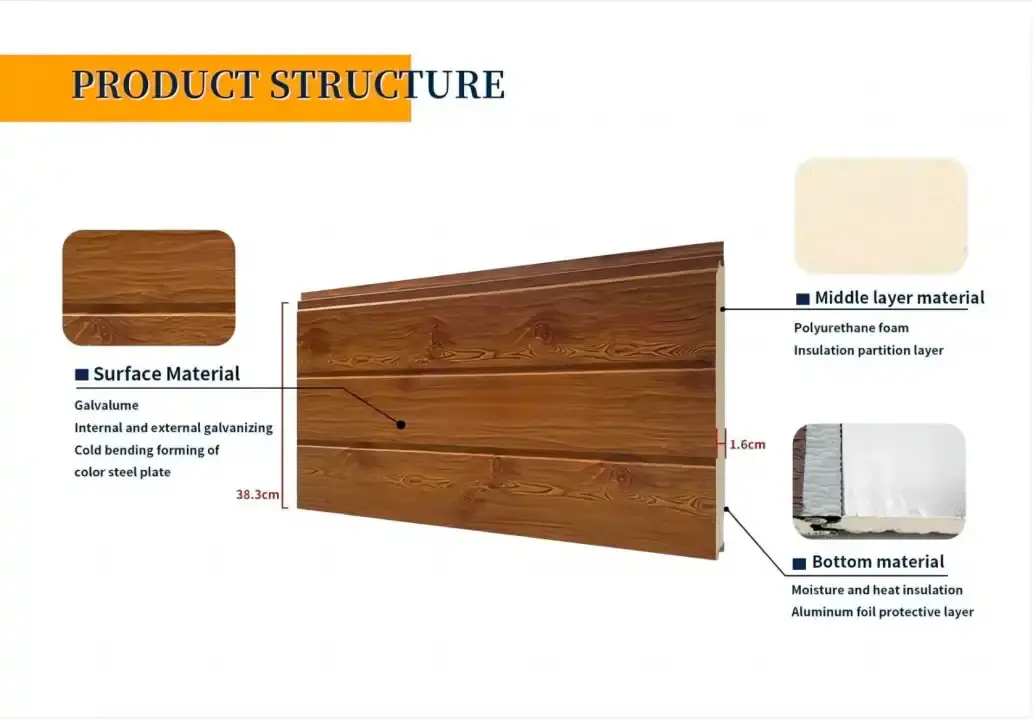

Metal insulated sandwich panels are a marvel of engineering, designed to maximize thermal efficiency while providing structural integrity. These panels consist of three key components: two metal facings and an insulating core. The metal facings, typically made of steel or aluminum, provide strength and durability, while the core material, often polyurethane or polyisocyanurate foam, delivers exceptional insulating properties.

Core Composition and Thermal Performance

The heart of a metal insulated sandwich panel lies in its core. This layer is crucial for thermal insulation, acting as a barrier against heat transfer. The insulating core in these panels is engineered to have low thermal conductivity, effectively minimizing heat loss or gain. This results in significant energy savings for heating and cooling, making metal insulated sandwich panels an eco-friendly choice for construction projects.

Metal Facings: More Than Just a Pretty Face

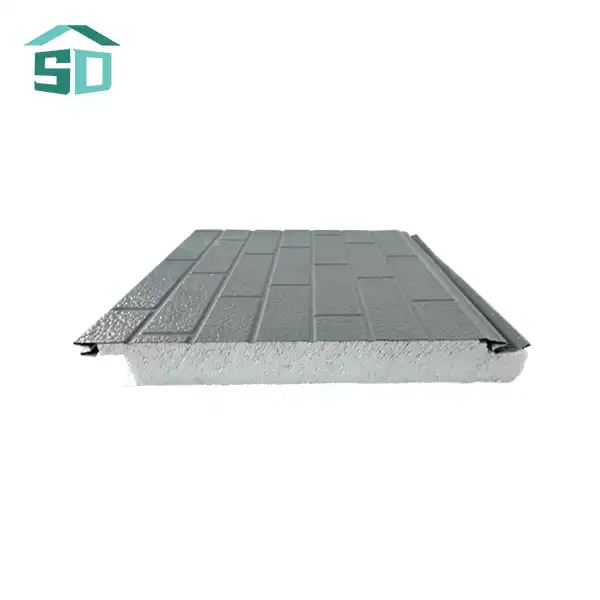

While the core handles insulation, the metal facings of sandwich panels serve multiple purposes. They provide structural support, weather resistance, and contribute to the overall thermal performance. The reflective properties of metal surfaces help in reducing radiant heat transfer, further enhancing the panel's insulating capabilities. Additionally, these facings can be customized in various colors and finishes, offering aesthetic flexibility without compromising on functionality.

Synergy of Components in Metal Insulated Sandwich Panels

The true magic of metal insulated sandwich panels happens when all components work in harmony. The combination of the insulating core and metal facings creates an air-tight seal, eliminating thermal bridges commonly found in traditional construction methods. This synergy not only improves thermal insulation but also enhances the overall energy efficiency of the building envelope.

Advantages of Using Metal Insulated Sandwich Panels for Thermal Insulation

The benefits of incorporating metal insulated sandwich panels in construction projects extend far beyond just thermal insulation. These versatile panels offer a range of advantages that make them an attractive option for both new constructions and renovations.

Superior Energy Efficiency with Metal Insulated Sandwich Panels

One of the primary advantages of metal insulated sandwich panels is their exceptional energy efficiency. The high-performance insulating core, combined with the reflective properties of metal facings, creates a formidable barrier against heat transfer. This results in reduced energy consumption for heating and cooling, leading to lower utility bills and a smaller carbon footprint. The energy-saving potential of these panels makes them an ideal choice for environmentally conscious builders and property owners.

Durability and Longevity of Metal Insulated Sandwich Panels

Metal insulated sandwich panels are built to last. The metal facings provide excellent resistance to weathering, corrosion, and impact damage. This durability translates to lower maintenance costs and a longer lifespan for the building envelope. Unlike traditional insulation methods that may degrade over time, the insulating core in these panels maintains its performance for many years, ensuring consistent thermal efficiency throughout the building's life.

Versatility in Design and Application of Metal Insulated Sandwich Panels

Architects and designers appreciate the flexibility offered by metal insulated sandwich panels. These panels can be customized in various colors, textures, and profiles to suit any architectural style. From sleek modern designs to traditional aesthetics, metal insulated sandwich panels can adapt to diverse project requirements. Their versatility extends to application as well, being suitable for walls, roofs, and even interior partitions in a wide range of building types.

Implementation and Best Practices for Metal Insulated Sandwich Panels

To fully leverage the benefits of metal insulated sandwich panels, proper implementation is crucial. Understanding the best practices for installation and maintenance can significantly enhance the performance and longevity of these panels.

Installation Techniques for Metal Insulated Sandwich Panels

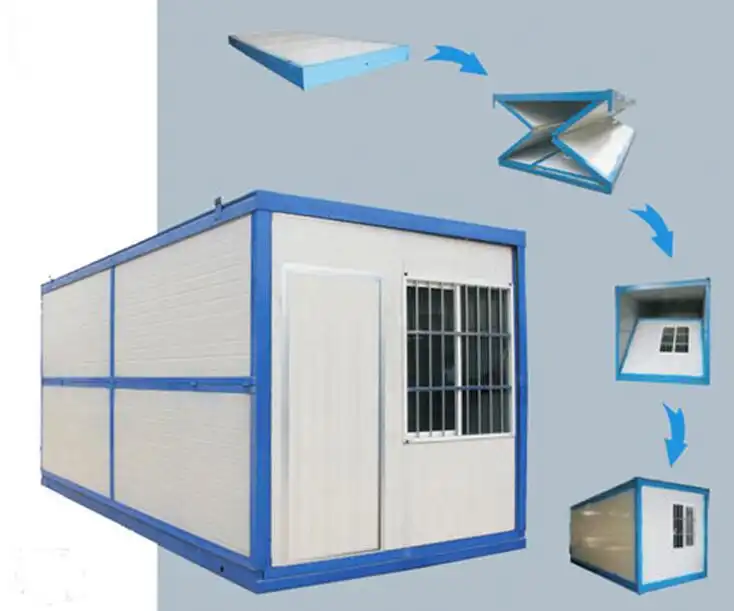

The installation of metal insulated sandwich panels requires precision and expertise. Proper alignment and sealing are essential to maintain the panel's thermal performance. Professional installers use specialized tools and techniques to ensure a tight fit between panels, eliminating gaps that could compromise insulation. The lightweight nature of these panels simplifies the installation process, reducing construction time and labor costs compared to traditional building methods.

Maintenance and Care of Metal Insulated Sandwich Panels

One of the advantages of metal insulated sandwich panels is their low maintenance requirements. Regular inspections to check for any damage or wear are typically sufficient. The smooth surfaces of these panels make them easy to clean, requiring only occasional washing to maintain their appearance. In the rare event of damage, individual panels can often be replaced without affecting the entire system, making repairs cost-effective and efficient.

Optimizing Performance of Metal Insulated Sandwich Panels

To maximize the thermal insulation benefits of metal insulated sandwich panels, it's important to consider the entire building envelope. This includes proper sealing around openings, adequate ventilation, and complementary insulation in areas not covered by panels. By taking a holistic approach to building design and construction, the full potential of metal insulated sandwich panels can be realized, resulting in a highly energy-efficient and comfortable structure.

Conclusion

Metal insulated sandwich panels have revolutionized thermal insulation in modern construction. Their unique combination of high-performance insulation, durability, and design flexibility makes them an ideal choice for a wide range of building projects. By providing superior energy efficiency, these panels not only contribute to reduced operational costs but also support sustainable building practices. As the construction industry continues to evolve, metal insulated sandwich panels stand out as a versatile and effective solution for thermal insulation challenges.

Are you looking to enhance the thermal efficiency of your next construction project? Consider the transformative power of metal insulated sandwich panels. At Weifang Sandong Building Materials Co., Ltd., we specialize in providing top-quality exterior cladding solutions, including state-of-the-art metal insulated sandwich panels. Our products combine unmatched thermal insulation with aesthetic versatility, offering you the perfect balance of performance and design. Whether you're planning a new build or a renovation, our expert team is ready to help you choose the ideal metal insulated sandwich panel for your needs. Contact us today at info@sdqsc.com to explore how our innovative solutions can elevate your project's energy efficiency and overall value.

FAQ

What makes metal insulated sandwich panels different from traditional insulation methods?

Metal insulated sandwich panels offer a complete system combining structural support, weatherproofing, and high-performance insulation in one product, unlike traditional methods that often require multiple layers and components.

Can metal insulated sandwich panels be used in both commercial and residential buildings?

Yes, these panels are versatile and can be applied to various building types, including offices, homes, warehouses, and more, offering excellent thermal insulation in all settings.

How do metal insulated sandwich panels contribute to energy efficiency?

The panels' advanced insulating core and reflective metal facings significantly reduce heat transfer, leading to lower energy consumption for heating and cooling, thus improving overall building energy efficiency.

References

1. American Iron and Steel Institute. (2021). "Steel Panel Systems in Construction: Benefits and Applications."

2. U.S. Department of Energy. (2022). "Building Envelope and Insulation Technologies."

3. International Journal of Engineering Research and Technology. (2020). "Thermal Performance Analysis of Insulated Metal Panels in Building Construction."

4. Building Science Corporation. (2021). "Insulated Metal Panels: Design and Performance Guidelines."

5. Energy Efficiency and Conservation Authority, New Zealand. (2022). "Commercial Building Insulation Best Practices."