Thermal Performance: PU Panels vs. Traditional Insulation

Superior R-Value and Energy Efficiency

PU insulated sandwich panels boast an impressive thermal performance that surpasses many traditional insulation materials. The polyurethane core of these panels provides exceptional insulating properties, with a thermal conductivity of ≤ 0.023 W/mK. This low thermal conductivity translates to a higher R-value per inch of thickness compared to materials like fiberglass or mineral wool. As a result, PU panels can achieve the same level of insulation with a thinner profile, maximizing usable space in buildings.

The superior insulation capabilities of PU insulated sandwich panels contribute significantly to energy efficiency in buildings. By effectively reducing heat transfer through walls and roofs, these panels help maintain consistent indoor temperatures, reducing the load on heating and cooling systems. This energy-saving feature not only leads to lower utility costs but also supports sustainable building practices by minimizing overall energy consumption.

Temperature Stability and Comfort

PU insulated sandwich panels excel in maintaining temperature stability within buildings. Unlike some traditional insulation materials that may compress or settle over time, the rigid structure of PU panels ensures consistent performance throughout their lifespan. This stability translates to improved comfort for building occupants, with fewer temperature fluctuations and drafts.

The effectiveness of PU panels in temperature control is particularly noticeable in extreme weather conditions. Whether facing scorching summer heat or frigid winter temperatures, buildings insulated with PU panels maintain a more comfortable indoor environment. This characteristic makes them an ideal choice for a wide range of climates and applications, from residential homes to commercial and industrial facilities.

Long-Term Performance and Durability

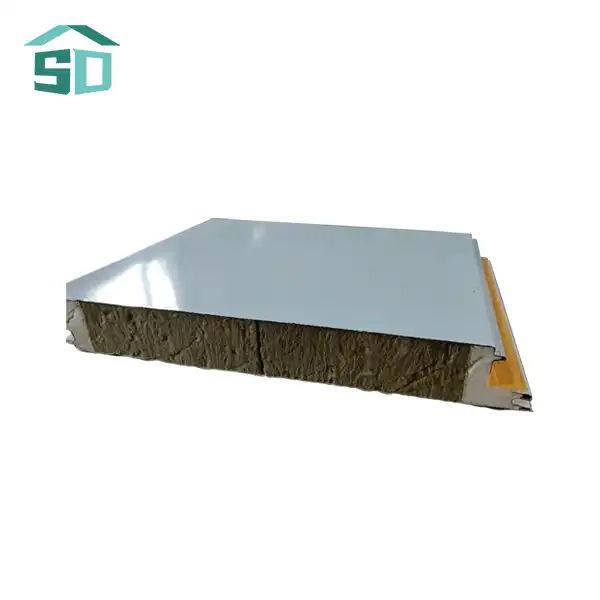

When comparing the long-term performance of insulation materials, PU insulated sandwich panels demonstrate exceptional durability. The closed-cell structure of polyurethane foam resists moisture absorption, preventing the degradation that can occur in some fibrous insulation materials when exposed to humidity. This moisture resistance not only maintains the insulation's effectiveness over time but also protects against mold growth and structural damage.

PU panels also retain their shape and insulating properties better than many alternative materials. While some insulation types may settle or compact over the years, reducing their effectiveness, PU insulated sandwich panels maintain their performance characteristics. This longevity ensures that buildings continue to benefit from optimal insulation throughout the panels' lifespan, reducing the need for frequent replacements or additional insulation measures.

Versatility and Application Range of PU Insulated Sandwich Panels

Adaptability to Various Building Types

PU insulated sandwich panels demonstrate remarkable versatility, making them suitable for a wide array of building types and architectural styles. From residential complexes and office buildings to industrial warehouses and agricultural structures, these panels adapt seamlessly to diverse construction needs. Their lightweight nature, coupled with high structural integrity, allows for creative design solutions that might be challenging with traditional building materials.

In residential applications, PU insulated sandwich panels offer homeowners the dual benefits of energy efficiency and aesthetic appeal. These panels can be customized with various finishes and colors, allowing them to complement or enhance the exterior design of homes. For commercial and industrial buildings, the panels provide a cost-effective solution for large-scale insulation needs while offering flexibility in design and rapid installation.

Customization and Design Flexibility

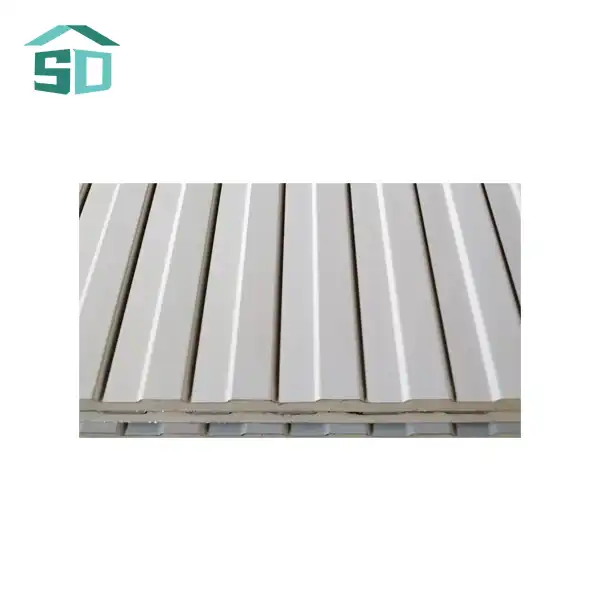

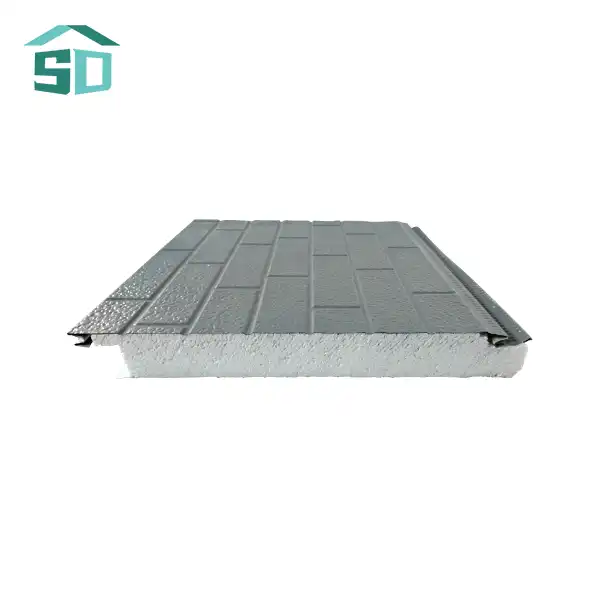

One of the standout features of PU insulated sandwich panels is their high degree of customization. PU insulated sandwich panel suppliers offer these panels in a range of thicknesses, typically from 50mm to 100mm, with custom sizes available to meet specific project requirements. This flexibility in sizing allows architects and builders to optimize insulation levels for different parts of a building or to meet varying regional building codes.

Beyond size customization, PU panels can be tailored in terms of surface finishes and colors. This versatility enables designers to create visually striking facades or to seamlessly integrate the panels with existing architectural elements. The ability to choose from various surface treatments, including coated, painted, or anodized options, further enhances the panels' adaptability to different aesthetic preferences and functional requirements.

Performance in Extreme Environments

PU insulated sandwich panels excel in challenging environmental conditions, outperforming many traditional insulation materials. Their resistance to moisture and temperature fluctuations makes them ideal for use in coastal areas or regions with high humidity. The panels' corrosion-resistant properties, particularly when paired with appropriate metal facings, ensure longevity even in harsh marine environments.

In areas prone to extreme temperatures, whether hot or cold, PU insulated sandwich panels maintain their insulating properties more effectively than many alternatives. This consistent performance across a wide temperature range makes them suitable for applications ranging from cold storage facilities to buildings in tropical climates. Additionally, the panels' fire-resistant properties, with options available in Class B1 and Class A2 fire ratings, enhance safety in various building types and locations.

Cost-Effectiveness and Installation Efficiency

Initial Investment vs. Long-Term Savings

When evaluating the cost-effectiveness of insulation materials, it's crucial to consider both the initial investment and long-term savings. While PU insulated sandwich panels may have a higher upfront cost compared to some traditional insulation options, their superior performance and durability often result in significant long-term savings. The exceptional thermal efficiency of PU panels leads to reduced energy consumption for heating and cooling, translating into lower utility bills over the building's lifespan.

The durability of PU insulated sandwich panels also contributes to their cost-effectiveness. With a longer service life and minimal maintenance requirements, these panels reduce the need for frequent replacements or repairs. This longevity not only saves on material costs but also minimizes disruptions to building operations that can occur during insulation upgrades or replacements.

Streamlined Installation Process

PU insulated sandwich panels offer significant advantages in terms of installation efficiency. Their modular design and lightweight nature allow for rapid installation, reducing labor costs and construction timelines. Unlike traditional insulation methods that may require multiple layers or components, PU panels come as pre-fabricated units that can be quickly and easily assembled on-site.

The ease of installation is particularly beneficial in large-scale projects or renovations where time is a critical factor. PU insulated sandwich panel suppliers often provide panels in customizable lengths up to 12,000mm, allowing for fewer joints and faster coverage of large areas. This efficiency not only speeds up the construction process but also minimizes the potential for installation errors, ensuring optimal performance of the insulation system.

Reduced Structural Load and Foundation Costs

The lightweight nature of PU insulated sandwich panels offers additional cost benefits in terms of structural requirements. Compared to heavier insulation materials or traditional building methods, PU panels place less load on the building's structural framework. This reduced weight can lead to savings in the design and construction of supporting structures, foundations, and load-bearing elements. Partnering with a reliable PU insulated sandwich panels supplier ensures not only these structural advantages but also consistent quality and dependable supply for every project.

In renovation projects, the use of PU insulated sandwich panels can be particularly advantageous. Their lightweight properties often allow for the addition of insulation without the need for significant structural reinforcements. This can make insulation upgrades more feasible and cost-effective, especially in older buildings where load-bearing capacity may be a concern.

Conclusion

PU insulated sandwich panels emerge as a superior choice in the realm of building insulation, offering a unique combination of thermal efficiency, versatility, and cost-effectiveness. Their exceptional insulating properties, coupled with durability and ease of installation, position them as a valuable solution for modern construction challenges. From energy savings and environmental performance to adaptability across various building types, PU panels demonstrate clear advantages over many traditional insulation materials. As the construction industry continues to evolve towards more sustainable and efficient practices, PU insulated sandwich panels stand out as a forward-thinking option for builders, architects, and property owners alike.

Are you looking for high-quality PU insulated sandwich panels for your next construction project? Look no further than Weifang Sandong Building Materials Co., Ltd. As a leading PU insulated sandwich panel supplier, we offer premium products that combine durability, insulation, and customization to meet your specific needs. Experience the benefits of our state-of-the-art panels and elevate your building's performance. Contact us today at info@sdqsc.com to learn more about our products and how we can support your construction goals.

FAQs

What are the main advantages of PU insulated sandwich panels?

PU insulated sandwich panels offer superior thermal insulation, durability, moisture resistance, and fire retardancy. They are lightweight, easy to install, and highly customizable.

How do PU panels compare to fiberglass insulation?

PU panels generally offer better insulation per inch of thickness, are more moisture-resistant, and maintain their shape better over time compared to fiberglass insulation.

Are PU insulated sandwich panels environmentally friendly?

Modern PU panels are produced with environmentally conscious methods and contribute to energy efficiency in buildings, reducing overall environmental impact.

What is the typical lifespan of PU insulated sandwich panels?

With proper installation and maintenance, PU panels can last for several decades, often outlasting many traditional insulation materials.

References

1. U.S. Department of Energy. (2023). Insulation Materials. Office of Energy Efficiency & Renewable Energy.

2. Building Science Corporation. (2022). Guide to Insulating Sheathing.

3. International Code Council. (2021). International Energy Conservation Code.

4. Polyurethane Foam Association. (2023). Technical Information on Polyurethane Foam.

5. American Society of Heating, Refrigerating and Air-Conditioning Engineers. (2021). ASHRAE Handbook - Fundamentals.