Preparing for Corrugated Steel Siding Panel Installation

Before diving into the installation process, thorough preparation is crucial for a successful corrugated steel siding panel project. This phase sets the foundation for a smooth installation and ensures the longevity of your siding.

Gathering Necessary Tools and Materials

To install corrugated steel siding panels efficiently, you'll need a specific set of tools and materials. Essential items include:

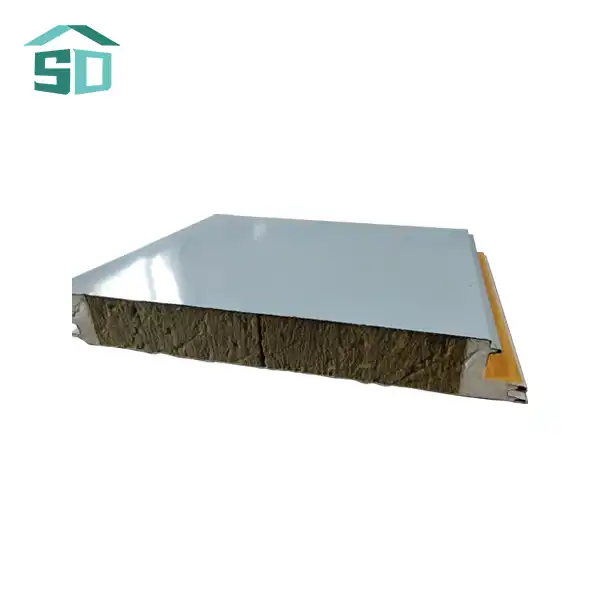

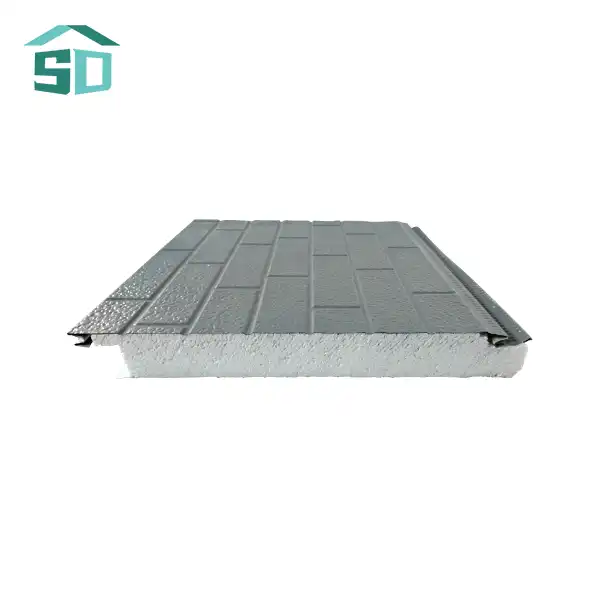

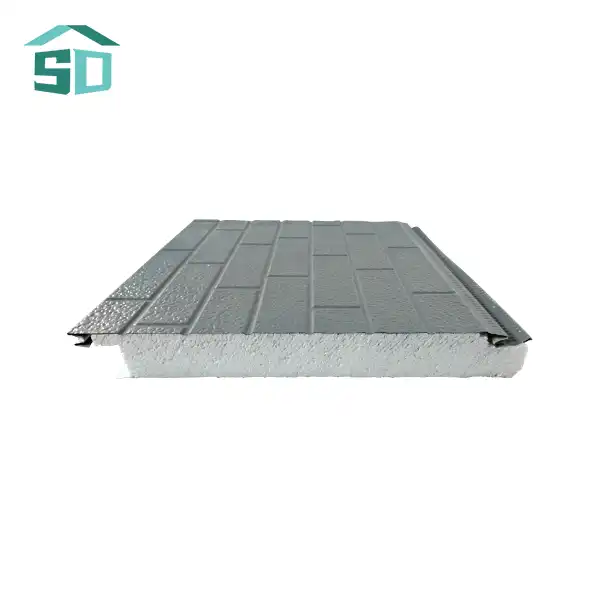

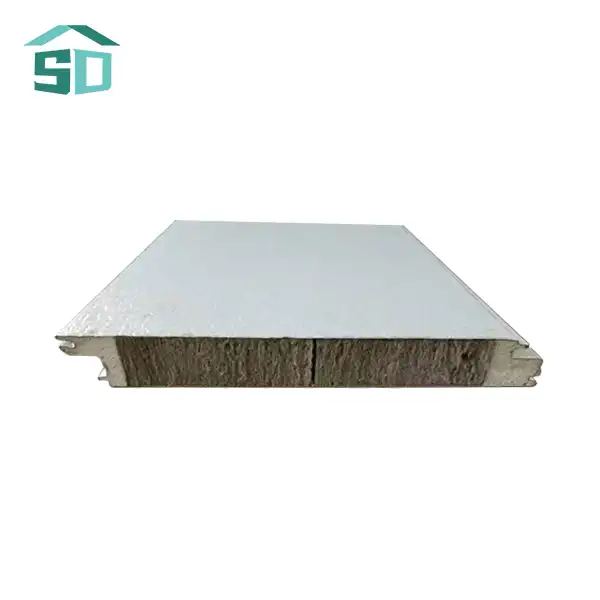

- Corrugated steel siding panels

- Measuring tape

- Chalk line

- Level

- Tin snips or circular saw with metal-cutting blade

- Drill with appropriate bits

- Screws or nails designed for metal siding

- Safety equipment (gloves, goggles, ear protection)

- Moisture barrier

- Flashing for windows, doors, and corners

- Caulk and caulking gun

Having these tools and materials ready before starting will streamline the installation process and prevent unnecessary delays.Measuring and Planning

Accurate measurements are paramount when installing corrugated steel siding panels. Begin by measuring the height and width of each wall, accounting for windows, doors, and other openings. Calculate the total square footage and add 10% for waste and mistakes. This extra material allows for errors and ensures you have enough panels to complete the job.

Create a detailed plan for panel layout, paying attention to the direction of installation and how panels will overlap. Consider the location of seams and how they will align with architectural features. A well-thought-out plan minimizes waste and creates a more visually appealing result.

Surface Preparation

Proper surface preparation is critical for the longevity and performance of your corrugated steel siding panels. Start by removing any existing siding, if applicable. Inspect the underlying structure for damage or rot, making necessary repairs before proceeding.

Install a moisture barrier over the sheathing to protect against water infiltration. This barrier is crucial for preventing moisture-related issues such as mold and rot. Ensure the barrier is properly overlapped and sealed at all seams.

If your building has uneven surfaces, consider installing furring strips to create a level surface for the siding panels. This step ensures a smooth, professional-looking finish and proper panel alignment.

Step-by-Step Installation Process

With thorough preparation complete, it's time to begin the installation of your corrugated steel siding panels. Following a systematic approach ensures a professional result and maximizes the benefits of this durable siding option.

Starting at the Bottom

Begin the installation process at the bottom of the wall, working your way up. This method allows water to flow down and away from the building, preventing moisture intrusion. Install a starter strip or J-channel at the bottom edge of the wall to provide a secure base for the first row of panels.

Use a level to ensure the starter strip is perfectly horizontal. This initial alignment is crucial as it sets the foundation for all subsequent rows. Secure the starter strip with appropriate fasteners, ensuring it's firmly attached to the structure.

Panel Installation Techniques

When installing corrugated steel siding panels, proper technique is essential for both aesthetics and functionality. Start by placing the first panel in the starter strip, ensuring it's level and plumb. Secure the panel using screws or nails specifically designed for metal siding, placing fasteners in the valleys of the corrugations to prevent water penetration.

As you install subsequent panels, maintain a consistent overlap between panels. The typical overlap for corrugated steel siding is one full corrugation, but always refer to the manufacturer's specifications for your specific product. This overlap is crucial for proper water drainage and a seamless appearance.

When cutting panels to fit around windows, doors, or at corners, use tin snips for small cuts or a circular saw with a metal-cutting blade for longer cuts. Always wear appropriate safety gear when cutting metal panels.

Sealing and Flashing

Proper sealing and flashing are critical for preventing water infiltration and ensuring the longevity of your corrugated steel siding installation. Apply caulk to all joints, including where panels meet trim pieces around windows and doors. Use a high-quality, exterior-grade sealant that remains flexible after curing to accommodate thermal expansion and contraction.

Install flashing around windows, doors, and at roof intersections to direct water away from these vulnerable areas. Overlap flashing with the siding panels to create a continuous water barrier. Pay special attention to corners, using corner flashing or trim pieces to create a clean, weather-tight seal.

Finishing Touches and Maintenance

As you near the completion of your corrugated steel siding panels installation, attention to detail in the finishing touches can elevate the overall appearance and functionality of your project.

Trim and Accessories

Install trim pieces around windows, doors, and at corners to create a polished, professional look. These accessories not only enhance the aesthetic appeal but also provide additional protection against water infiltration. Use J-channel around openings to create a clean edge for cut panel ends. Consider installing soffit and fascia to complete the exterior look and provide additional protection for your roof's eaves. These elements contribute to proper attic ventilation and prevent pests from entering the roof space.

Final Inspection and Cleanup

Once all panels and trim pieces are installed, conduct a thorough inspection of your work. Check for any loose fasteners, gaps in caulking, or areas where flashing may need adjustment. Address any issues promptly to ensure the integrity of your siding installation. Clean up the work area, removing any metal shavings or debris that could potentially cause rust stains on your new siding. Use a soft brush or cloth to gently clean the panels, removing any dirt or fingerprints accumulated during installation.

Long-term Maintenance

While corrugated steel siding panels are known for their durability and low maintenance requirements, regular care can extend their lifespan and maintain their appearance. Develop a maintenance routine that includes:

- Annual inspections to check for damage or loose panels

- Cleaning the siding with mild soap and water to remove dirt and debris

- Reapplying caulk or sealant as needed to maintain water-tight seals

- Touching up any scratches or minor damage to prevent rust

By following these maintenance practices, you can ensure your corrugated steel siding continues to protect and beautify your building for years to come.Conclusion

Installing corrugated steel siding panels like a pro requires meticulous planning, precise execution, and attention to detail. By following the steps outlined in this guide, from thorough preparation to careful installation and finishing touches, you can achieve a durable, attractive exterior that enhances your building's aesthetics and protection. Remember that proper sealing, flashing, and maintenance are key to maximizing the longevity and performance of your corrugated steel siding panels. With the right approach, your siding will provide lasting beauty and protection for your structure.

At Weifang Sandong Building Materials Co., Ltd., we understand the importance of quality materials in achieving superior results. Our corrugated steel siding panels are designed for durability, ease of installation, and aesthetic appeal. Whether you're tackling a DIY project or managing a large-scale construction, our products and expertise can help you achieve professional-grade results. For more information on our corrugated steel siding panels or other exterior cladding solutions, please contact us at info@sdqsc.com.

FAQ

What are the advantages of using corrugated steel siding panels?

Corrugated steel siding panels offer durability, low maintenance, fire resistance, and energy efficiency. They are also versatile in design and can enhance a building's aesthetic appeal.

How long do corrugated steel siding panels typically last?

With proper installation and maintenance, corrugated steel siding panels can last 40-70 years, depending on the quality of the material and environmental conditions.

Can corrugated steel siding panels be painted?

Yes, corrugated steel siding panels can be painted to change their appearance or refresh their look. However, it's important to use paint specifically designed for metal surfaces and follow proper preparation techniques.

References

1.Metal Construction Association. (2021). "Metal Cladding Installation Guide."

2.American Iron and Steel Institute. (2020). "Steel Siding Installation Manual."

3.U.S. Department of Energy. (2022). "Guide to Exterior Siding Materials."

4.National Association of Home Builders. (2021). "Best Practices for Siding Installation."

5.Journal of Architectural Engineering. (2019). "Comparative Study of Exterior Cladding Materials."