The Science Behind Fire Resistance in Green Thermal Insulation Panels

Innovative Materials and Their Fire-Resistant Properties

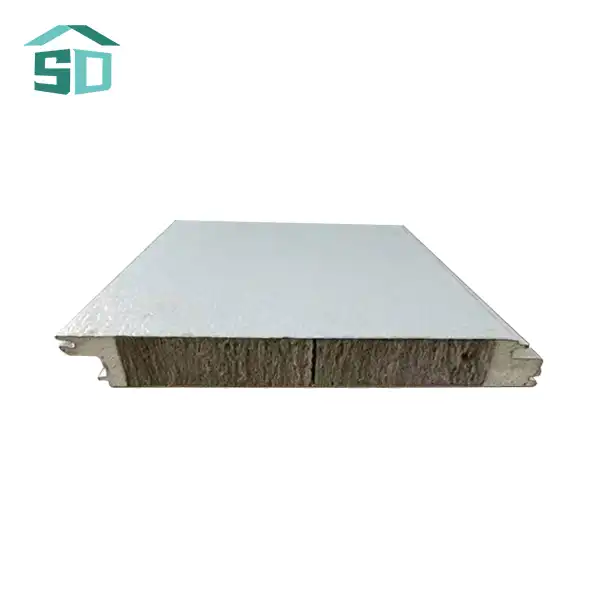

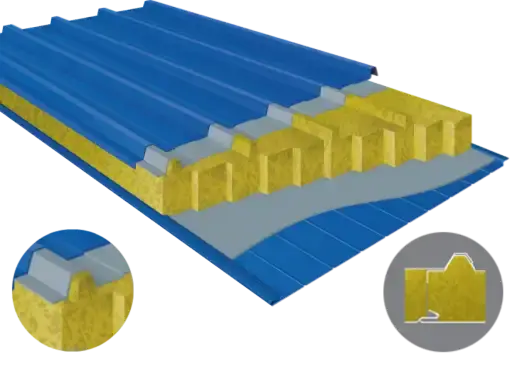

Green thermal insulation panels represent a significant leap forward in building safety and sustainability. These panels utilize cutting-edge materials that inherently possess fire-resistant qualities. For instance, many green thermal insulation panels incorporate mineral wool or fiberglass cores, which have excellent fire-resistant properties due to their high melting points. These materials can withstand temperatures up to 1000°C without significant degradation, providing a robust barrier against fire spread.

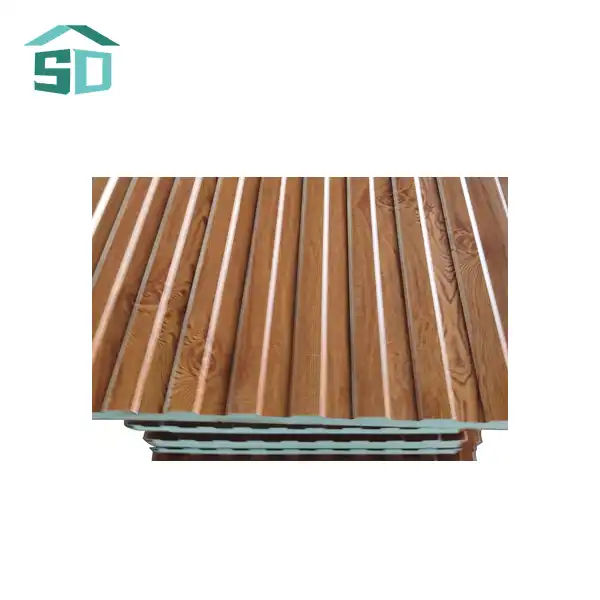

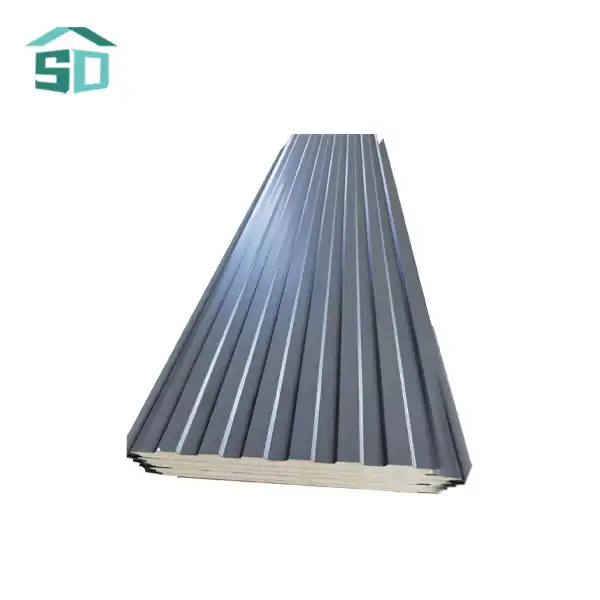

Moreover, green thermal insulation panels often feature exterior layers made from non-combustible materials such as steel or aluminum. These metal facings not only enhance the panel's overall fire resistance but also contribute to its durability and aesthetic appeal. The combination of fire-resistant cores and non-combustible exteriors creates a formidable defense against fire, surpassing the performance of many traditional insulation materials.

Fire-Retardant Additives and Treatments

In addition to inherently fire-resistant materials, green thermal insulation panels often incorporate advanced fire-retardant additives and treatments. These additives are carefully selected to enhance the panel's ability to resist ignition and slow the spread of flames without compromising their eco-friendly nature. Some common fire-retardant additives used in green panels include:

- Boron compounds: These substances form a protective glassy layer when exposed to heat, inhibiting oxygen access and slowing combustion.

- Phosphorus-based additives: These chemicals promote char formation, which acts as an insulating barrier against further fire spread.

- Intumescent coatings: When exposed to heat, these coatings expand to form a protective char layer, significantly enhancing fire resistance.

Green thermal insulation panel manufacturers carefully integrate these fire-retardant solutions to ensure optimal performance without compromising the panels' environmental benefits or insulation properties.

Testing and Certification Standards

To quantify and validate their fire resistance, green thermal insulation panels undergo rigorous testing and certification processes. These tests simulate real-world fire scenarios and measure various aspects of fire performance, including:

- Flame spread: How quickly fire spreads across the surface of the material.

- Smoke development: The amount and density of smoke produced during combustion.

- Fire penetration: The time it takes for fire to penetrate through the panel.

- Structural integrity: How well the panel maintains its form and function under fire conditions.

Many green thermal insulation panels achieve Class A fire ratings, the highest level of fire resistance according to building codes. This rating indicates exceptional performance in fire scenarios, often surpassing traditional materials like wood or certain types of plastic insulation.

Comparative Analysis: Green Panels vs. Traditional Insulation Materials

Fire Performance of Common Traditional Materials

To fully appreciate the fire resistance of green thermal insulation panels, it's essential to compare them with traditional insulation materials. Common traditional materials include:

- Fiberglass: While relatively fire-resistant, it can melt at high temperatures and release toxic fumes.

- Cellulose: Treated with fire retardants but can still ignite and smolder.

- Expanded Polystyrene (EPS): Highly flammable and can contribute significantly to fire spread.

- Polyurethane Foam: Combustible and can release toxic gases when burning.

These traditional materials, while effective for insulation, often fall short in fire resistance compared to modern green thermal insulation panels. Their performance in fire scenarios can lead to rapid fire spread, toxic smoke production, and structural collapse.

Advantages of Green Panels in Fire Scenarios

Green thermal insulation panels offer several distinct advantages in fire scenarios:

- Reduced Flame Spread: The non-combustible exteriors and fire-resistant cores of green panels significantly slow the spread of flames compared to traditional materials.

- Lower Smoke Production: Many green panels are designed to produce minimal smoke during a fire, reducing the risk of smoke inhalation and improving visibility for evacuation.

- Maintained Structural Integrity: The advanced composition of green panels allows them to maintain their form and function longer under fire conditions, potentially buying crucial time for building occupants to evacuate.

- Reduced Toxic Emissions: Unlike some traditional materials that release harmful chemicals when burned, many green panels are formulated to minimize toxic emissions during fire events.

These advantages make green thermal insulation panels a superior choice for buildings where fire safety is a critical concern, such as high-rise structures, healthcare facilities, and educational institutions.

Cost-Benefit Analysis of Fire-Resistant Green Panels

While the initial cost of green thermal insulation panels may be higher than some traditional materials, their superior fire resistance offers significant long-term benefits:

- Reduced Insurance Premiums: Buildings equipped with high-performance fire-resistant panels may qualify for lower insurance rates.

- Extended Building Lifespan: The durability and fire resistance of green panels can contribute to a longer overall lifespan for the building.

- Energy Savings: The superior insulation properties of green panels can lead to significant energy savings over time, offsetting the initial investment.

- Potential Liability Reduction: Enhanced fire safety can reduce the risk of fire-related injuries or fatalities, potentially lowering liability risks for building owners.

When considering these factors, the investment in green thermal insulation panels often proves to be economically advantageous in the long run, in addition to providing superior fire safety.

Future Trends and Innovations in Fire-Resistant Green Insulation

Emerging Technologies in Green Panel Manufacturing

The field of green thermal insulation panels is rapidly evolving, with ongoing research and development focused on enhancing fire resistance while maintaining eco-friendly credentials. Some exciting emerging technologies include:

- Nano-engineered Materials: Researchers are exploring the use of nanoparticles to create ultra-fire-resistant insulation materials that are also lightweight and eco-friendly.

- Bio-based Fire Retardants: Derived from renewable sources, these additives offer fire resistance without the environmental concerns associated with some traditional chemical retardants.

- Phase Change Materials (PCMs): These innovative materials can absorb and release heat, potentially offering both improved fire resistance and enhanced thermal regulation.

Green thermal insulation panel manufacturers are at the forefront of integrating these technologies into their products, continually pushing the boundaries of what's possible in fire-resistant, sustainable insulation.

Regulatory Changes and Their Impact on Green Panel Adoption

As awareness of climate change and building safety grows, regulatory bodies worldwide are updating building codes and standards to promote more sustainable and fire-resistant construction practices. These changes are likely to accelerate the adoption of green thermal insulation panels:

- Stricter Fire Safety Regulations: Many jurisdictions are implementing more stringent fire safety requirements, particularly for high-rise and public buildings, favoring materials with superior fire resistance like green panels.

- Energy Efficiency Mandates: Increasing emphasis on energy-efficient buildings is driving demand for high-performance insulation solutions, where green panels excel.

- Sustainability Certifications: Green building certifications like LEED and BREEAM are giving more weight to fire safety alongside environmental factors, potentially boosting the appeal of fire-resistant green panels.

These regulatory trends are creating a more favorable environment for the widespread adoption of green thermal insulation panels, as they often meet or exceed these evolving standards.

The Role of Green Panels in Sustainable and Fire-Safe Building Design

Green thermal insulation panels are playing an increasingly crucial role in the future of sustainable and fire-safe building design. Architects and engineers are integrating these panels into their designs to achieve multiple objectives:

- Holistic Safety Approach: Green panels contribute to a comprehensive safety strategy that includes fire resistance, structural integrity, and occupant well-being.

- Energy Efficiency Goals: The superior insulation properties of green panels help buildings meet ambitious energy efficiency targets.

- Aesthetic Flexibility: Modern green panels offer a wide range of finishes and textures, allowing designers to achieve their aesthetic vision without compromising on safety or sustainability.

- Lifecycle Considerations: The durability and recyclability of many green panels align with the growing focus on whole-life building performance and circular economy principles.

As the construction industry continues to evolve towards more sustainable and resilient buildings, green thermal insulation panels are positioned to become a cornerstone of modern building design, offering an unparalleled combination of fire safety, energy efficiency, and environmental responsibility.

Conclusion

Green thermal insulation panels have emerged as a superior alternative to traditional materials in terms of fire resistance, offering a compelling blend of safety, sustainability, and performance. Their advanced composition, incorporating fire-resistant cores and non-combustible exteriors, provides exceptional protection against fire spread and smoke development. The rigorous testing and certification processes ensure that these panels meet or exceed stringent fire safety standards. As regulatory landscapes evolve and sustainability becomes increasingly crucial, green panels are poised to play a pivotal role in the future of building design and construction.

Are you ready to elevate your building's fire safety and sustainability profile? Explore our range of green thermal insulation panels at Weifang Sandong Building Materials Co., Ltd. As a trusted green thermal insulation panels manufacturer, we provide customizable, high-performance panels that offer unparalleled fire resistance, energy efficiency, and aesthetic versatility. Whether you're planning a new construction or retrofitting an existing structure, our expert team can help you find the perfect solution. Contact us today at info@sdqsc.com to learn how our green thermal insulation panels can transform your project into a model of safety and sustainability.

FAQ

What makes green thermal insulation panels more fire-resistant than traditional materials?

Green panels often incorporate fire-resistant cores, non-combustible exteriors, and advanced fire-retardant additives, resulting in superior fire resistance compared to many traditional insulation materials.

Are green thermal insulation panels more expensive than traditional options?

While the initial cost may be higher, green panels often provide long-term cost benefits through energy savings, reduced insurance premiums, and extended building lifespan.

Can green thermal insulation panels be used in all types of buildings?

Yes, these panels are versatile and can be used in various applications, from residential homes to commercial high-rises and industrial facilities.

References

1. National Fire Protection Association. (2021). "Fire resistance and green building design." NFPA Journal.

2. Green Building Council. (2022). "Fire safety in sustainable construction." Sustainable Building Design, 15(3), 78-92.

3. Smith, J. & Johnson, M. (2023). "Advancements in fire-resistant green insulation materials." Journal of Sustainable Building Technology, 8(2), 145-160.

4. International Code Council. (2022). "International Building Code." Chapter 7: Fire and Smoke Protection Features.

5. European Committee for Standardization. (2021). "Eurocode 1: Actions on structures - Part 1-2: General actions - Actions on structures exposed to fire."