Introducing Insulated Wall Panels: A Comprehensive Overview

What are Insulated Wall Panels?

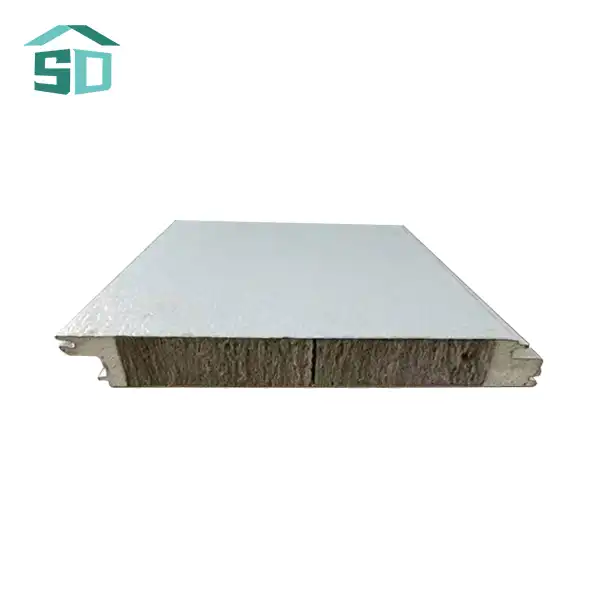

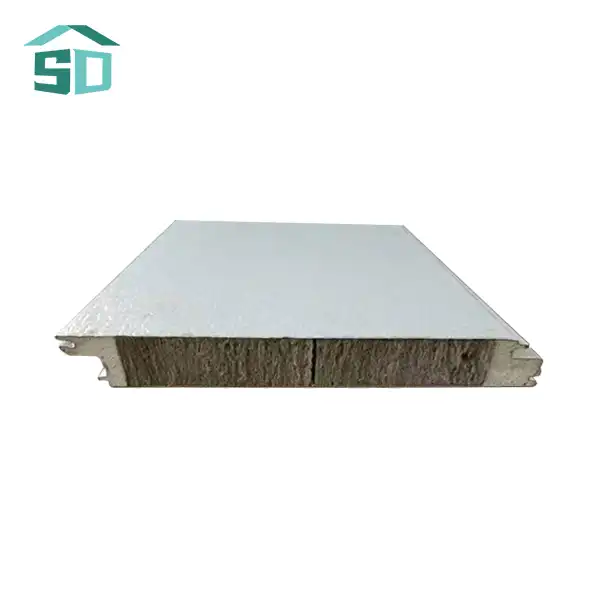

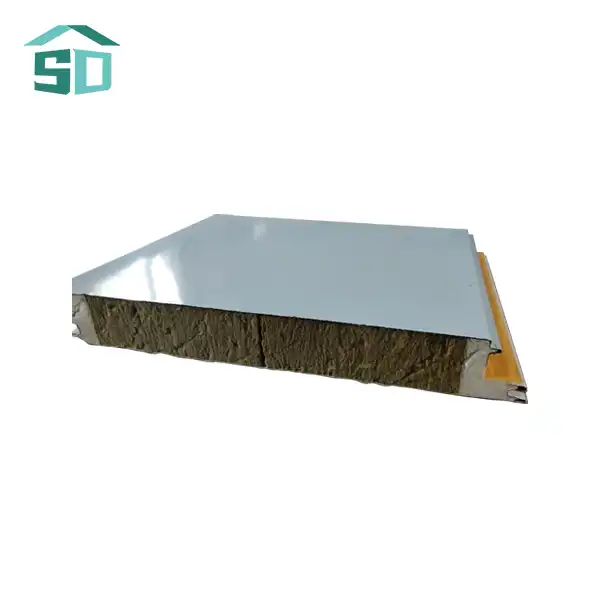

Insulated wall panels are innovative building components that combine structural support and thermal insulation in a single, prefabricated unit. These panels typically consist of two metal facings with a core of insulating material, such as polyurethane foam or expanded polystyrene. The design of insulated wall panels allows for quick and easy installation, making them an increasingly popular choice in modern construction projects.

As a leading insulated wall panels manufacturer, Weifang Sandong Building Materials Co., Ltd. produces high-quality panels that offer excellent thermal performance and durability. Our advanced production lines and rigorous quality control system ensure that each panel meets the highest standards of performance and aesthetics.

Types of Insulated Wall Panels

There are several types of insulated wall panels available in the market, each with its own unique characteristics and applications:

- Polyurethane (PUR) Panels: Known for their superior insulation properties and fire resistance.

- Expanded Polystyrene (EPS) Panels: Lightweight and cost-effective, suitable for various applications.

- Mineral Wool Panels: Offer excellent fire resistance and sound insulation properties.

- Phenolic Panels: Provide high thermal performance in a thin profile.

The choice of panel type depends on specific project requirements, including thermal performance, fire safety, and budget considerations. Our expert team at Weifang Sandong Building Materials Co., Ltd. can guide you in selecting the most suitable insulated wall panels for your project.

Benefits of Using Insulated Wall Panels

Insulated wall panels offer numerous advantages over traditional insulation methods:

- Enhanced Energy Efficiency: The continuous insulation provided by these panels minimizes thermal bridging, resulting in superior energy performance.

- Faster Installation: Pre-fabricated panels significantly reduce on-site construction time.

- Improved Air Tightness: The seamless installation of insulated wall panels helps create a more airtight building envelope.

- Versatility: These panels can be used in various applications, from residential to commercial and industrial buildings.

- Aesthetic Appeal: Available in a wide range of finishes and colors, insulated wall panels can enhance the visual appeal of any structure.

By choosing insulated wall panels from Weifang Sandong Building Materials Co., Ltd., you're not only investing in high-quality products but also benefiting from our commitment to innovation and customer satisfaction.

Installation Process: Insulated Wall Panels vs. Traditional Methods

Traditional Insulation Installation Methods

Traditional insulation methods typically involve multiple steps and materials, which can be time-consuming and labor-intensive. The process often includes:

1. Framing the wall structure

2. Installing a vapor barrier

3. Fitting insulation materials (e.g., fiberglass batts or blown-in insulation)

4. Adding an air barrier

5. Installing exterior sheathing

6. Applying a weather barrier

7. Attaching the exterior cladding

This multi-step process requires careful coordination between different trades and can be prone to errors or gaps in insulation, potentially compromising the building's thermal performance.

Insulated Wall Panel Installation Process

In contrast, the installation of insulated wall panels is a streamlined process that offers significant time and labor savings:

1. Preparation of the building structure

2. Lifting and positioning of the insulated wall panels

3. Securing panels to the structure using specialized fasteners

4. Sealing joints between panels

5. Installing trims and flashings

This simplified process not only reduces installation time but also minimizes the potential for errors and improves overall quality control. As a leading insulated wall panels manufacturer, Weifang Sandong Building Materials Co., Ltd. provides comprehensive installation guidelines and support to ensure optimal performance of our products.

Comparison of Labor Requirements

The labor requirements for installing insulated wall panels are significantly lower compared to traditional insulation methods. While traditional methods may require multiple specialized crews working on different aspects of the wall assembly, insulated wall panel installation can often be completed by a single, trained team.

This reduction in labor not only contributes to cost savings but also simplifies project management and reduces the potential for scheduling conflicts on the construction site. The efficiency of insulated wall panel installation is particularly beneficial in large-scale projects or those with tight deadlines.

Cost Analysis: Insulated Wall Panels vs. Traditional Insulation

Initial Material Costs

When comparing the initial material costs, insulated wall panels may appear more expensive than traditional insulation materials. However, it's crucial to consider that insulated wall panels combine multiple components into a single product:

- Structural support

- Insulation material

- Vapor barrier

- Air barrier

- Exterior finishing

When these individual components are factored in, the cost difference between insulated wall panels and traditional methods becomes less significant. Additionally, as a reputable insulated wall panels manufacturer, Weifang Sandong Building Materials Co., Ltd. offers competitive pricing without compromising on quality.

Labor Costs and Time Savings

The real cost advantage of insulated wall panels becomes evident when considering labor costs and installation time. The simplified installation process of insulated wall panels results in:

- Reduced labor hours

- Fewer specialized trades required on-site

- Shorter project timelines

- Lower equipment rental costs

These factors can lead to substantial cost savings, especially on larger projects. The accelerated construction schedule also allows for earlier occupancy or faster project completion, which can have significant financial benefits for building owners and developers.

Long-Term Cost Considerations

When evaluating the cost-effectiveness of insulated wall panels, it's essential to consider long-term benefits:

- Energy Savings: The superior thermal performance of insulated wall panels can lead to significant reductions in heating and cooling costs over the building's lifetime.

- Maintenance Costs: The durable nature of insulated wall panels often results in lower maintenance requirements compared to traditional wall assemblies.

- Potential Tax Incentives: In some regions, the use of energy-efficient building materials like insulated wall panels may qualify for tax incentives or rebates.

- By choosing high-quality insulated wall panels from Weifang Sandong Building Materials Co., Ltd., building owners can enjoy these long-term cost benefits while also contributing to more sustainable and energy-efficient construction practices.

Conclusion

In conclusion, while the initial material costs of insulated wall panels may be higher than traditional insulation methods, the overall installation costs are often lower due to reduced labor requirements and faster installation times. The streamlined process of installing insulated wall panels offers significant time and cost savings, particularly in large-scale projects. Moreover, the long-term benefits of improved energy efficiency, reduced maintenance, and potential tax incentives make insulated wall panels a cost-effective choice for modern construction.

If you're considering insulated wall panels for your next construction project, look no further than Weifang Sandong Building Materials Co., Ltd. Our high-quality products and expert support can help you achieve optimal performance and cost-effectiveness in your building envelope. Contact us today at info@sdqsc.com to learn more about our insulated wall panels and how they can benefit your project.

FAQ

Are insulated wall panels suitable for all types of buildings?

Insulated wall panels are versatile and can be used in various building types, including residential, commercial, and industrial structures. However, the specific panel type and installation method may vary depending on the building's requirements.

How long do insulated wall panels typically last?

High-quality insulated wall panels, like those manufactured by Weifang Sandong Building Materials Co., Ltd., can last for several decades with proper maintenance. The exact lifespan depends on factors such as environmental conditions and the specific panel type.

Can insulated wall panels be used in retrofitting existing buildings?

Yes, insulated wall panels can be an excellent option for retrofitting existing buildings to improve their energy efficiency. However, the installation process may require additional considerations compared to new construction projects.

References

1. U.S. Department of Energy. (2021). "Insulation Materials." Energy.gov.

2. International Code Council. (2018). "International Energy Conservation Code." ICC Digital Codes.

3. National Institute of Building Sciences. (2020). "Whole Building Design Guide: Building Envelope Design Guide." WBDG.org.

4. American Society of Heating, Refrigerating and Air-Conditioning Engineers. (2019). "ASHRAE Handbook—Fundamentals." ASHRAE.org.

5. Building Science Corporation. (2018). "Building Science Insights: Insulation Effectiveness." BuildingScience.com.