Introducing Fireproof Insulation Panels: Composition and Testing

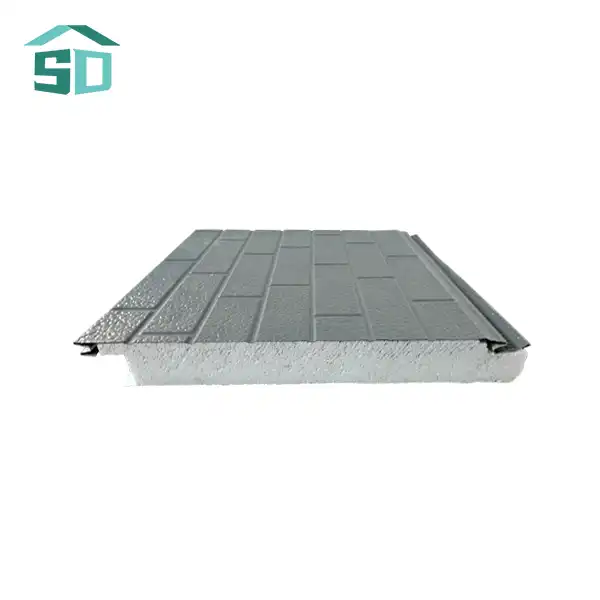

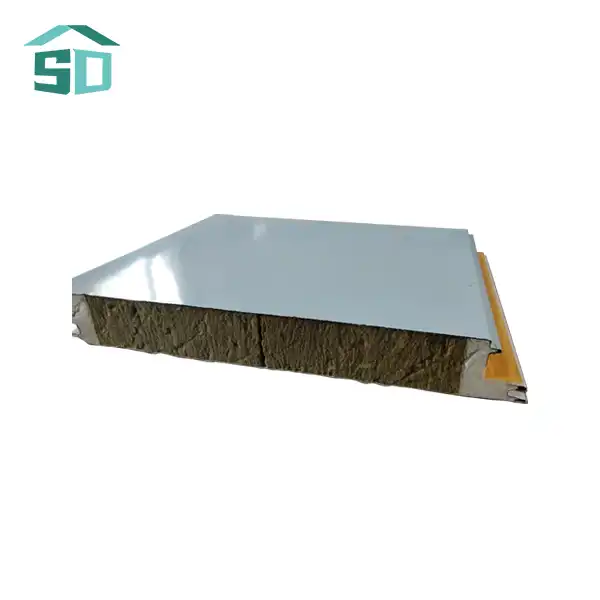

Fireproof insulation panels are engineered to provide exceptional fire resistance while maintaining excellent thermal insulation properties. These panels typically consist of a core material sandwiched between two metal facings, creating a robust barrier against fire and heat transfer.

Core Materials and Their Fire-Resistant Properties

The core of fireproof insulation panels plays a crucial role in their fire-resistant capabilities. Common core materials include:

- Mineral wool: Offers excellent fire resistance and thermal insulation

- Polyisocyanurate (PIR): Provides high thermal efficiency and good fire performance

- Phenolic foam: Known for its superior fire resistance and low smoke emission

- Glass wool: Offers non-combustible properties and good sound insulation

Each core material undergoes specific treatments and formulations to enhance its fire-resistant properties, ensuring optimal performance in fire scenarios.

Rigorous Testing Procedures for Fire Resistance

Fireproof insulation panels are subjected to a battery of tests to evaluate their fire performance. These tests simulate real-world fire conditions and assess various aspects of the panels' behavior under extreme heat. Key testing procedures include:

- Fire resistance tests: Measure the panel's ability to maintain structural integrity and insulation during a fire

- Flame spread tests: Evaluate how quickly flames propagate across the panel's surface

- Smoke development tests: Assess the amount and toxicity of smoke produced during combustion

- Heat release rate tests: Determine the panel's contribution to fire growth

These tests are conducted by accredited laboratories and follow internationally recognized standards, ensuring consistent and reliable results.

Certification Standards and Their Significance

Certification is a critical aspect of fireproof insulation panels, providing assurance to architects, builders, and end-users about the product's performance and safety. Various certification bodies and standards exist worldwide, each with its own set of criteria and testing protocols.

Key Certification Bodies and Their Requirements

Several respected organizations offer certification for fireproof insulation panels, including:

- Underwriters Laboratories (UL): Provides UL listings for fire-resistant assemblies

- Factory Mutual (FM): Offers FM Approvals for fire protection products

- European Committee for Standardization (CEN): Issues EN standards for fire-resistant construction products

- International Code Council (ICC): Evaluates building products for compliance with building codes

Each certification body has specific requirements and testing methodologies that panels must meet to receive their seal of approval.

Interpreting Fire Ratings and Classifications

Fire ratings and classifications provide valuable information about a panel's fire performance. Common rating systems include:

- Fire Resistance Rating: Expressed in hours, indicating how long a panel can maintain its integrity during a fire

- Flame Spread Index: A numerical value representing the rate at which flames spread across a surface

- Smoke Developed Index: Measures the amount of smoke generated during a fire test

- European Fire Classification: Ranging from A1 (non-combustible) to F (easily flammable)

Understanding these ratings helps in selecting the appropriate fireproof insulation panels for specific building requirements and local fire codes.

Applications and Benefits of Certified Fireproof Wall Panels

Tested and certified fireproof insulation panels offer numerous advantages in various construction applications, making them an increasingly popular choice among architects and builders.

Versatile Applications in Construction

Fireproof insulation panels find use in a wide range of building types and structures, including:

- Commercial buildings: Offices, retail spaces, and warehouses

- Industrial facilities: Manufacturing plants and storage facilities

- Residential complexes: Multi-story apartments and condominiums

- Educational institutions: Schools, universities, and research centers

- Healthcare facilities: Hospitals and medical centers

- Transportation hubs: Airports, train stations, and bus terminals

Their versatility extends to both interior and exterior applications, providing comprehensive fire protection throughout a structure.

Key Benefits of Using Certified Fireproof Panels

The use of tested and certified fireproof insulation panels offers several significant advantages:

- Enhanced fire safety: Slows fire spread and provides crucial time for evacuation

- Improved energy efficiency: Excellent thermal insulation properties reduce heating and cooling costs

- Noise reduction: Many panels offer superior sound insulation, creating quieter indoor environments

- Durability: Resistant to moisture, corrosion, and UV radiation, ensuring long-term performance

- Aesthetic flexibility: Available in various colors and finishes to match architectural designs

- Quick installation: Prefabricated panels allow for faster construction times

- Reduced insurance premiums: Buildings with certified fireproof panels may qualify for lower insurance rates

These benefits contribute to safer, more efficient, and cost-effective building solutions.

Conclusion

Tested and certified fireproof insulation panels represent a significant advancement in building safety and performance. Their rigorous testing procedures, stringent certification standards, and diverse applications make them an indispensable component of modern construction. By providing superior fire resistance, energy efficiency, and design flexibility, these panels contribute to safer, more sustainable buildings. As fire safety regulations continue to evolve, the importance of using certified fireproof panels in construction projects cannot be overstated.

Experience the unparalleled safety and efficiency of our fireproof insulation panels. At Weifang Sandong Building Materials Co., Ltd., we offer a wide range of tested and certified panels to meet your specific project needs. From custom sizes to various core materials, our products combine durability, insulation, and fire safety with easy installation and aesthetic appeal. Elevate your construction projects with our state-of-the-art fireproof panels. For more information or to discuss your requirements, contact us at info@sdqsc.com.

FAQ

What makes fireproof insulation panels different from traditional insulation?

Fireproof insulation panels are specifically engineered to resist fire, combining insulation properties with fire-resistant materials. They undergo rigorous testing to meet strict fire safety standards, offering superior protection compared to traditional insulation.

How long can fireproof insulation panels withstand fire?

The fire resistance duration varies depending on the panel's composition and thickness. Many certified panels can maintain their integrity for 1-3 hours during a fire, as indicated by their fire resistance rating.

Are fireproof insulation panels suitable for residential use?

Yes, these panels are excellent for residential applications, offering enhanced safety, energy efficiency, and sound insulation for homes, apartments, and multi-family dwellings.

How do I maintain fireproof insulation panels?

Maintenance is typically minimal. Regular visual inspections for damage and cleaning with mild detergent and water are usually sufficient to maintain their appearance and integrity.

References

1.International Code Council. (2021). International Building Code.

2.National Fire Protection Association. (2022). NFPA 285: Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Wall Assemblies Containing Combustible Components.

3.Underwriters Laboratories. (2023). UL 263 Standard for Fire Tests of Building Construction and Materials.

4.European Committee for Standardization. (2022). EN 13501-1: Fire classification of construction products and building elements.