The Science Behind Aluminum Foam Sandwich Panel's Thermal Efficiency

Understanding the Structure of Aluminum Foam Sandwich Panels

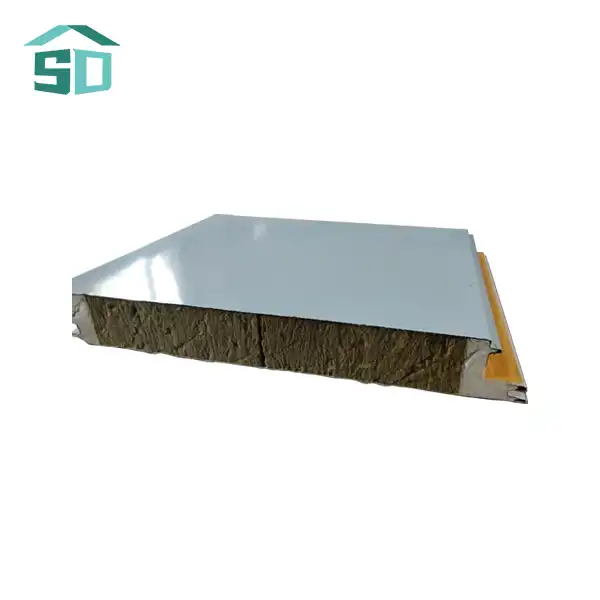

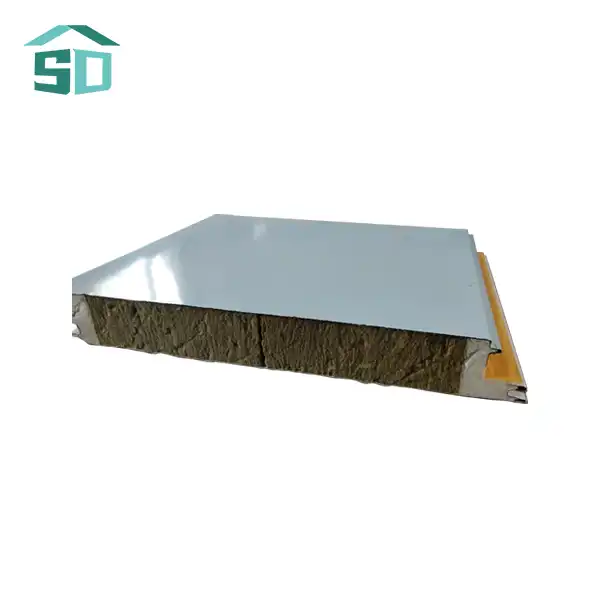

Aluminum foam sandwich panels are a marvel of modern engineering, combining lightweight design with remarkable strength. The panel consists of three key components: two thin, solid aluminum face sheets and a core made of aluminum foam. This structure is the secret behind its exceptional thermal insulation properties.

The aluminum foam core is the star player in the panel's insulation performance. It's created through a specialized process that introduces gas bubbles into molten aluminum, resulting in a material that's up to 95% air by volume. This porous structure is crucial for thermal insulation, as air is an excellent insulator.

Heat Transfer Mechanisms and How Aluminum Foam Counteracts Them

To understand why aluminum foam sandwich panels are so effective at thermal insulation, we need to look at the three main mechanisms of heat transfer: conduction, convection, and radiation.

- Conduction: The transfer of heat through direct contact, is significantly reduced by the foam's structure. The numerous air pockets in the foam create barriers to heat flow, as air is a poor conductor of heat. The thin cell walls of the foam further limit conduction pathways.

- Convection: Heat transfer through the movement of fluids or gases, is minimized by the closed-cell structure of the foam. The tiny, isolated air pockets prevent air circulation, reducing convective heat transfer.

- Radiation: The transfer of heat through electromagnetic waves, is also addressed by the aluminum foam. The metal's reflective properties help to bounce back a portion of radiant heat, further enhancing the panel's insulation capabilities.

Quantifying the Thermal Performance

The thermal efficiency of aluminum foam sandwich panels can be quantified through several key metrics:

- Thermal Conductivity: At 0.018 W/m.K, the thermal conductivity of these panels is exceptionally low, indicating superior insulation properties. For comparison, solid aluminum has a thermal conductivity of about 205 W/m.K, showcasing the dramatic improvement achieved by the foam structure.

- Thermal Resistance: With a value of 2.09 m²K/W, the thermal resistance (R-value) of these panels is impressive. This high R-value translates to excellent insulation performance, helping to maintain desired indoor temperatures with less energy expenditure.

These metrics underscore the panel's ability to create a formidable thermal barrier, making it an ideal choice for energy-efficient building envelopes.

Practical Applications and Benefits in Construction

Versatility in Building Design

Aluminum foam sandwich panels offer remarkable versatility in construction applications. Their lightweight nature, coupled with high strength, allows for creative architectural designs that would be challenging with traditional materials. These panels can be used in both interior and exterior applications, making them suitable for walls, roofs, and even decorative elements.

For exterior use, panels are available in thicknesses of 16mm or 20mm, with a width of 383mm. Interior applications can utilize thinner 10mm panels with a width of 450mm. This flexibility in dimensions allows architects and builders to tailor the panels to specific project requirements.

Energy Efficiency and Cost Savings

The superior thermal insulation properties of aluminum foam sandwich panels translate directly into energy savings for building owners. By creating a more effective thermal envelope, these panels reduce the load on heating and cooling systems, leading to lower energy consumption and reduced utility costs.

Moreover, the panels' durability and resistance to corrosion (with a waterproof rate of 0.0008) ensure long-term performance, minimizing maintenance and replacement costs over the building's lifetime. This combination of energy efficiency and longevity makes aluminum foam sandwich panels a cost-effective solution for modern construction projects.

Enhanced Building Performance

Beyond thermal insulation, aluminum foam sandwich panels contribute to overall building performance in several ways:

- Fire Resistance: With a fire-protection rating of B1/B2, these panels enhance building safety by reducing fire spread risks.

- Wind Resistance: Capable of withstanding wind pressures up to 8.0 kPa, the panels are suitable for use in areas prone to high winds.

- Acoustic Insulation: The foam structure also provides some degree of sound insulation, contributing to a quieter indoor environment.

- Customizable Aesthetics: Available in various colors and patterns, these panels allow for design flexibility without compromising on performance.

Innovations and Future Trends in Aluminum Foam Sandwich Panel Technology

Advancements in Manufacturing Processes

The production of aluminum foam sandwich panels is an area of ongoing innovation. Researchers and manufacturers are continually refining the foaming process to create even more uniform and controlled cellular structures. These improvements aim to enhance the panels' thermal insulation properties while maintaining or improving their structural integrity.

One promising development is the use of 3D printing technology to create custom foam structures. This could allow for panels with tailored thermal properties, optimized for specific climate conditions or building requirements.

Integration with Smart Building Technologies

As the construction industry moves towards smarter, more connected buildings, aluminum foam sandwich panels are poised to play a crucial role. Innovations in this area include:

- Embedded Sensors: Integrating temperature and humidity sensors within the panels to provide real-time data on building envelope performance.

- Phase Change Materials (PCMs): Incorporating PCMs into the foam structure to enhance thermal energy storage and further improve temperature regulation.

These advancements could transform aluminum foam sandwich panels from passive insulation elements into active components of a building's energy management system.

Sustainability and Environmental Considerations

The construction industry's growing focus on sustainability is driving innovations in aluminum foam sandwich panel technology. Future trends in this area include:

- Recycled Content: Increasing the use of recycled aluminum in panel production to reduce the environmental impact.

- Bio-based Foams: Exploring the potential of incorporating bio-based materials into the foam structure for a more eco-friendly product.

- End-of-Life Recycling: Developing more efficient methods for separating and recycling the components of used panels.

These initiatives aim to enhance the already impressive environmental credentials of aluminum foam sandwich panels, making them an even more attractive option for green building projects.

Conclusion

Aluminum foam sandwich panels represent a significant leap forward in building insulation technology. Their unique structure, combining a lightweight aluminum foam core with solid aluminum face sheets, provides exceptional thermal insulation properties. With impressive metrics like a thermal conductivity of 0.018 W/m.K and thermal resistance of 2.09 m²K/W, these panels offer a powerful solution for energy-efficient construction.

The versatility of aluminum foam sandwich panels, available in various thicknesses and widths for both interior and exterior applications, makes them suitable for a wide range of construction projects. Their benefits extend beyond thermal insulation, offering fire resistance, wind resistance, and customizable aesthetics.

For those interested in leveraging the benefits of aluminum foam sandwich panels in their construction projects, Weifang Sandong Building Materials Co., Ltd. offers expert guidance and high-quality products. To learn more about our exterior cladding and facade solutions, including aluminum foam sandwich panels, please contact us at info@sdqsc.com.