The Evolution of Insulation: From Traditional Methods to Metal Insulated Sandwich Panels

The quest for effective building insulation has been ongoing for centuries. Traditional insulation methods, such as straw, wool, and later fiberglass, have served their purpose but often come with limitations. Enter the metal insulated sandwich panel – a revolutionary product that has transformed the insulation landscape.

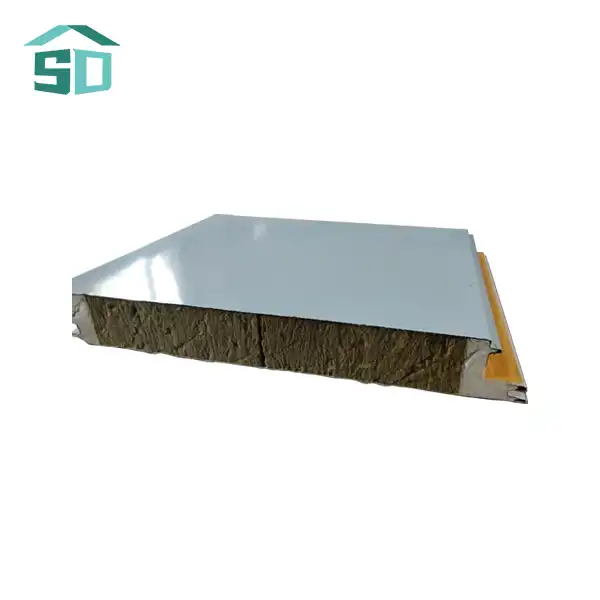

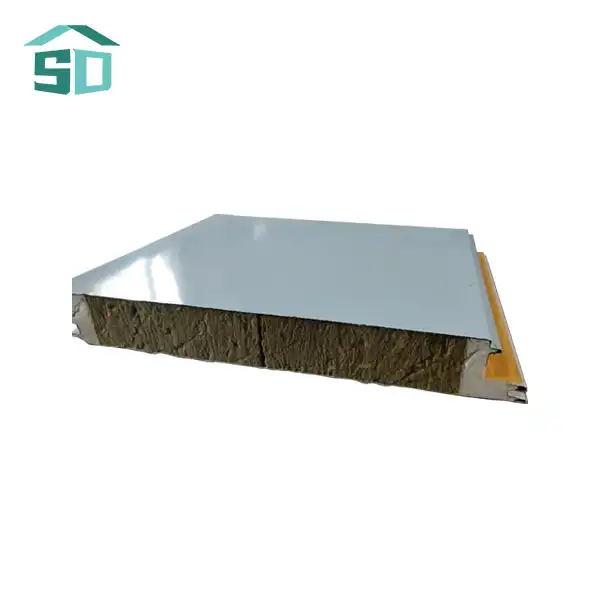

Metal insulated sandwich panels consist of two metal facings with an insulating core, typically made of polyurethane (PU) or polyisocyanurate (PIR). This unique construction offers several advantages over traditional insulation:

Superior Thermal Performance

The insulating core found in metal sandwich panels delivers outstanding thermal performance, with a low thermal conductivity of 0.018 W/m·K and a high thermal resistance of 2.09 m²·K/W. These characteristics allow it to slow down heat transfer far better than many conventional insulation materials. As a result, indoor spaces stay cooler during the summer and warmer in the winter, reducing the need for heating and cooling systems. This helps cut down on energy usage and creates a more comfortable living environment year-round. The consistent temperature also improves overall indoor comfort, making the space more pleasant to live or work in, all while contributing to energy savings.

Unmatched Durability

Unlike traditional insulation materials that may break down or lose their effectiveness over time from moisture or wear, metal insulated panels are built to last. Their durable design ensures consistent performance, providing reliable insulation for the long haul without the common issues associated with other materials. The metal facings create a strong, protective barrier that shields the insulating core from external threats, including moisture, pests, and physical damage. This durability helps preserve the insulation's efficiency, allowing the panels to maintain consistent thermal performance throughout the life of the building. With these panels, property owners can enjoy lasting energy savings and a reduced need for maintenance or replacements.

Versatility in Application

Metal insulated sandwich panels are incredibly versatile, making them ideal for various construction needs. Their unique design allows them to be used for both interior and exterior applications, providing a seamless aesthetic and functional solution. Whether it's for modern residential complexes, corporate office buildings, or more specialized uses like the renovation of historic buildings, these panels offer excellent insulation without compromising on design. They're also perfect for smaller structures, such as security kiosks, where both durability and thermal efficiency are essential. This flexibility makes them an excellent choice for a wide array of projects.

Comparing Performance: Metal Insulated Panels vs. Traditional Insulation

When it comes to performance, metal insulated sandwich panels consistently outshine traditional insulation methods across various parameters:

Energy Efficiency

The exceptional thermal properties of metal insulated panels, with their low thermal conductivity and high thermal resistance, make them an ideal choice for energy efficiency. These panels effectively reduce heat transfer, helping maintain a stable indoor temperature throughout the year. This results in lower heating and cooling costs for building owners and occupants, making them a more sustainable and cost-effective option. Their energy-saving capabilities not only contribute to environmental goals but also lead to significant financial savings over time.

Moisture Resistance

With a waterproof rate of just 0.0008, metal insulated panels offer outstanding protection against moisture infiltration. This is particularly important for preventing mold growth, which can lead to health issues and damage to the building's interior. Moreover, the ability to resist moisture helps preserve the overall structural integrity of the building, keeping walls dry and free from decay. Unlike traditional insulation materials that can absorb water, metal insulated panels ensure that moisture doesn't compromise the longevity and durability of the building, making them a reliable choice for various climates and environments.

Fire Safety

Metal insulated sandwich panelsare known for their impressive fire safety credentials, boasting fire-protection ratings of B1/B2. This non-combustible nature makes them an excellent choice for buildings where fire safety is a top priority. Traditional insulation materials often struggle to offer the same level of protection, as they can contribute to fire spread. In contrast, metal insulated panels act as a barrier, slowing the spread of flames and providing more time for evacuation and emergency response. This added layer of fire resistance enhances the safety of both building occupants and the overall structure.

Structural Strength

The metal facings of metal insulated sandwich panels add considerable structural strength to the building. With wind resistance of 8.0 KPa and a compressive strength of 52.7 kPa, these panels are built to endure harsh weather, including strong winds and heavy loads. This makes them particularly ideal for regions prone to extreme weather, where building stability is crucial. Using these panels in construction enhances the structure's durability, making it better equipped to handle environmental stresses and ensuring long-term safety and stability.

The Economic and Environmental Case for Metal Insulated Sandwich Panels

Beyond their superior performance, metal insulated sandwich panels offer compelling economic and environmental benefits:

Long-term Cost Savings

While metal insulated sandwich panels may come with a higher initial cost compared to traditional insulation options, their long-term savings make them a wise economic choice. These panels are highly energy-efficient, significantly lowering heating and cooling costs over time. Their robust durability and minimal maintenance needs mean fewer repairs, reducing long-term expenses. Additionally, their extended lifespan decreases the frequency of replacements, lowering the total cost of ownership. Taking into account the overall savings on energy bills and maintenance, metal insulated panels provide substantial economic benefits, making them a smart investment for building owners looking to maximize cost-effectiveness.

Streamlined Installation

Installing metal insulated panels is much more straightforward than traditional insulation systems, which typically require several layers of materials to achieve comparable performance. These panels integrate insulation, vapor barriers, and exterior finishes into one unified product, streamlining the construction process. This all-in-one design not only speeds up installation but also cuts down on labor costs, allowing projects to be completed more quickly. Furthermore, with fewer components to manage and install, the risk of errors is minimized, leading to a more efficient and smoother construction experience.

Sustainability

Metal insulated sandwich panels are a sustainable building solution, aligning with eco-friendly construction practices. Their energy-efficient properties help reduce a building's overall carbon footprint by minimizing energy consumption for heating and cooling. In addition, the durability of metal insulated panels minimizes the need for replacements, reducing construction waste. Many manufacturers incorporate recyclable materials in the production of these panels, boosting their environmental benefits. By opting for metal insulated panels, builders play a key role in promoting a more sustainable construction process. This choice not only benefits the environment by minimizing waste but also ensures a healthier, more energy-efficient living space for the building's occupants.

Aesthetic Flexibility

Unlike traditional insulation, which is often concealed behind walls, metal insulated panels combine both insulation and exterior finishing into one solution. These panels come in a variety of colors, finishes, and textures, allowing architects and designers to craft buildings with unique, appealing aesthetics. This versatility means that the design can be tailored to fit specific styles without compromising the performance of the insulation. It's a practical and stylish choice, delivering both visual appeal and effective thermal management for any building.

Conclusion

The comparison between metal insulated panels and traditional insulation methods clearly favors the former. Metal insulated sandwich panels offer a comprehensive solution that addresses the multifaceted needs of modern construction – from superior insulation and durability to aesthetic flexibility and sustainability. As building regulations become more stringent and energy efficiency gains paramount importance, the adoption of metal insulated panels is set to accelerate.

For those seeking to elevate their building projects with state-of-the-art insulation solutions, Weifang Sandong Building Materials Co., Ltd. stands ready to assist. Our advanced production lines and rigorous quality control ensure that every metal insulated sandwich panel meets the highest standards of performance and durability. To learn more about our products and how they can benefit your next construction project, please contact us at info@sdqsc.com.