Understanding the Composition and Properties of WPC and Fiber-Cement Cladding

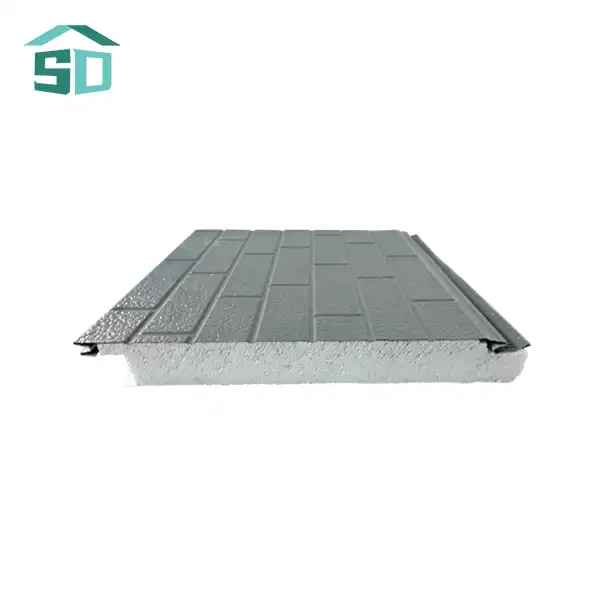

WPC Exterior Wall Cladding Panels: A Modern Marvel

Wood Plastic Composite (WPC) exterior wall cladding panels represent a significant advancement in building materials. These panels combine wood fibers or flour with thermoplastics, resulting in a product that marries the best qualities of both components. The wood content in WPC cladding panels typically ranges from 50% to 70%, with the remainder being plastic and additives.

The unique composition of WPC exterior wall cladding panels contributes to their exceptional properties. They boast remarkable resistance to moisture, rot, and insect infestation—issues that often plague traditional wood cladding. The plastic component provides excellent weather resistance, allowing these panels to maintain their appearance and structural integrity even in harsh environmental conditions.

Moreover, WPC exterior wall cladding panels offer impressive dimensional stability. Unlike pure wood products, they resist warping, swelling, and shrinking due to temperature and humidity changes. This stability ensures that the cladding maintains a smooth, uniform appearance over time, reducing the need for frequent repairs or replacements.

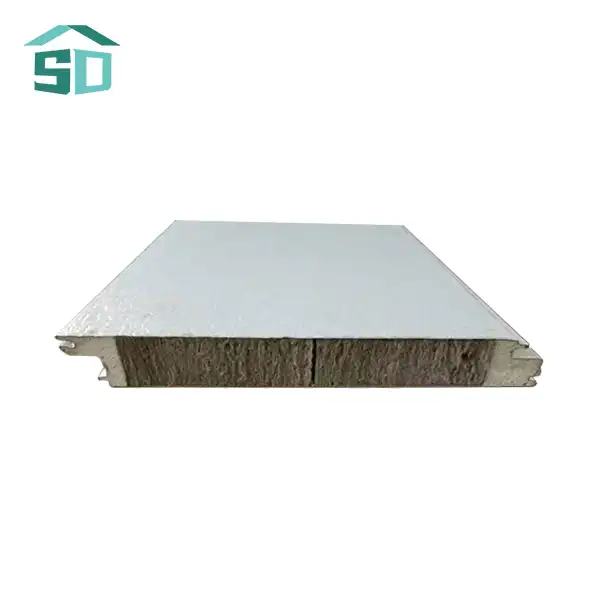

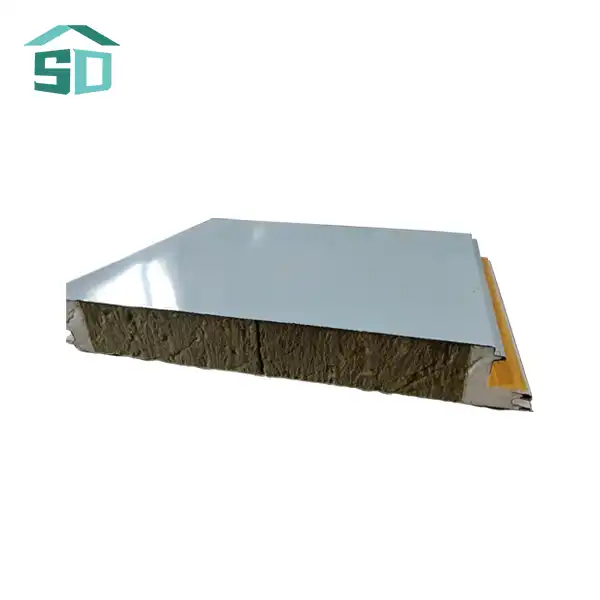

Fiber-Cement: The Time-Tested Cladding Solution

Fiber-cement exterior wall cladding panels, on the other hand, have a longer history in the construction industry. These panels are made from a mixture of Portland cement, sand, cellulose fibers, and other additives. The result is a durable, fire-resistant material that can mimic the appearance of wood, stucco, or masonry.

The composition of fiber-cement exterior wall cladding panels gives them several advantageous properties. They are notably fire-resistant, often achieving high fire ratings that make them suitable for use in areas prone to wildfires. The cement content also provides excellent resistance to rot, insects, and impact damage.

Fiber-cement exterior wall cladding panels are also known for their longevity. When properly installed and maintained, these panels can last for decades, making them a cost-effective choice for many building projects. Their durability extends to color retention as well, with many fiber-cement products resisting fading and maintaining their original appearance for years.

Comparing Performance and Durability of WPC and Fiber-Cement Cladding

Weather Resistance and Longevity of WPC Exterior Wall Cladding Panels

WPC exterior wall cladding panels excel in weather resistance, thanks to their plastic component. They effectively repel water, preventing moisture absorption that can lead to rot or mold growth. This makes WPC cladding an excellent choice for regions with high humidity or frequent rainfall.

The durability of WPC exterior wall cladding panels is also noteworthy. They resist scratches, dents, and impacts better than many traditional cladding materials. This resilience translates to a longer lifespan, with many WPC products carrying warranties of 25 years or more.

However, it's important to note that prolonged exposure to intense sunlight can potentially cause some fading or chalking in WPC exterior wall cladding panels. While many manufacturers incorporate UV stabilizers to mitigate this effect, the degree of color retention can vary between products.

Strength and Resilience of Fiber-Cement Cladding

Fiber-cement exterior wall cladding panels are renowned for their robustness. They can withstand extreme weather conditions, including high winds, hail, and freeze-thaw cycles. This resilience makes them a popular choice in regions prone to severe weather events.

The fire resistance of fiber-cement exterior wall cladding panels is particularly impressive. Many fiber-cement products achieve Class A fire ratings, the highest possible classification. This makes them an excellent choice for buildings in fire-prone areas or where stringent fire codes apply.

Fiber-cement cladding also resists rot, insects, and fungal growth, contributing to its long-term durability. However, these panels can be more susceptible to moisture-related issues if not properly installed or maintained. Ensuring proper installation and regular maintenance is crucial to maximizing the longevity of fiber-cement exterior wall cladding panels.

Aesthetic Versatility and Maintenance Requirements

Design Flexibility of WPC Exterior Wall Cladding Panels

WPC exterior wall cladding panels offer a wide range of design possibilities. They can be manufactured to mimic the look of natural wood, complete with realistic grain patterns and textures. This allows architects and homeowners to achieve the warmth and beauty of wood without the associated maintenance concerns.

The color options for WPC exterior wall cladding panels are virtually limitless. They can be produced in a wide spectrum of hues, from natural wood tones to bold, contemporary colors. Some manufacturers even offer customizable color options, allowing for truly unique facade designs.

In terms of maintenance, WPC exterior wall cladding panels are relatively low-maintenance. They don't require painting or staining, and regular cleaning with soap and water is usually sufficient to keep them looking their best. This low maintenance requirement can translate to significant cost savings over the life of the cladding.

Aesthetic Options and Upkeep of Fiber-Cement Cladding

Fiber-cement exterior wall cladding panels also offer considerable aesthetic versatility. They can be manufactured to resemble various materials, including wood, stone, and brick. This versatility allows for a wide range of architectural styles, from traditional to contemporary.

One advantage of fiber-cement exterior wall cladding panels is that they can be painted. This allows for easy color changes if desired, providing flexibility in maintaining or updating a building's appearance over time. Many fiber-cement products come pre-painted from the factory, with finishes designed to last for many years.

Maintenance requirements for fiber-cement cladding are generally moderate. While they don't require the frequent upkeep of wood, they may need repainting every 7-15 years, depending on the product and environmental conditions. Regular cleaning and inspection for any signs of damage or wear are also recommended to ensure the longevity of fiber-cement exterior wall cladding panels.

Conclusion

Both WPC and fiber-cement exterior wall cladding panels offer compelling advantages for modern construction projects. WPC excels in moisture resistance and low maintenance, while fiber-cement shines in fire resistance and traditional aesthetics. The choice between these materials often comes down to specific project requirements, climate considerations, and personal preferences. As exterior wall cladding panel manufacturers continue to innovate, both materials are likely to see further improvements in performance and sustainability.

At Weifang Sandong Building Materials Co., Ltd., we understand the importance of choosing the right exterior wall cladding panel for your project. Our expert team is ready to guide you through the selection process, ensuring you find the perfect solution that balances aesthetics, performance, and cost-effectiveness. Whether you're leaning towards the modern appeal of WPC or the classic durability of fiber-cement, we have the products and expertise to meet your needs. Contact us at info@sdqsc.com to explore our range of exterior wall cladding panels and take the first step towards transforming your building's facade.

FAQ

What are the main differences between WPC and fiber-cement exterior wall cladding panels?

WPC panels are made from wood fibers and plastic, offering excellent moisture resistance and low maintenance. Fiber-cement panels, composed of cement, sand, and cellulose fibers, provide superior fire resistance and a traditional appearance.

Which material is more durable for exterior cladding?

Both materials are highly durable, but they excel in different areas. WPC is more resistant to moisture and rot, while fiber-cement offers better fire resistance and impact strength.

Are WPC exterior wall cladding panels environmentally friendly?

Many WPC panels use recycled materials, making them a more eco-friendly option. However, the environmental impact can vary depending on the specific product and manufacturer.

References

1.Building Science Corporation. (2021). "Cladding Systems for High-Performance Buildings."

2.Journal of Building Engineering. (2020). "Comparative Study of WPC and Fiber-Cement Cladding Materials."

3.American Society for Testing and Materials. (2022). "Standard Specification for Fiber-Cement Siding."

4.International Journal of Polymer Science. (2019). "Advances in Wood-Plastic Composites as Building Materials."