Grasping Thermal Insulation in Exterior Wall Cladding

Thermal insulation is a crucial factor in building design and construction, directly impacting energy efficiency and occupant comfort. Exterior wall cladding panels play a significant role in a building's thermal performance by creating a barrier between the interior and exterior environments. The effectiveness of this barrier is measured by its R-value, which indicates the material's resistance to heat flow. Higher R-values equate to better insulation properties.

The Science Behind Thermal Insulation

The thermal insulation provided by exterior wall cladding panels relies on several key principles of physics. These panels work by reducing heat transfer through conduction, convection, and radiation. The most effective exterior wall cladding panels incorporate materials with low thermal conductivity, such as expanded polystyrene (EPS) or polyurethane foam. These materials contain millions of tiny air pockets that slow down heat transfer, significantly enhancing the panel's insulating capabilities.

Factors Affecting Insulation Performance

Several factors influence the thermal insulation performance of exterior wall cladding panels:

- Material composition: The type of insulating material used in the panel core greatly affects its R-value.

- Thickness: Generally, thicker panels provide better insulation.

- Density: Higher density insulation materials often offer improved thermal resistance.

- Installation quality: Proper installation is crucial to minimize thermal bridges and ensure optimal performance.

- Climate conditions: The effectiveness of insulation can vary depending on local climate factors.

Top-Performing Exterior Wall Cladding Panels for Thermal Insulation

When seeking the highest thermal insulation, certain types of exterior wall cladding panels stand out for their exceptional performance. These advanced solutions combine innovative materials and designs to achieve superior R-values and energy efficiency.

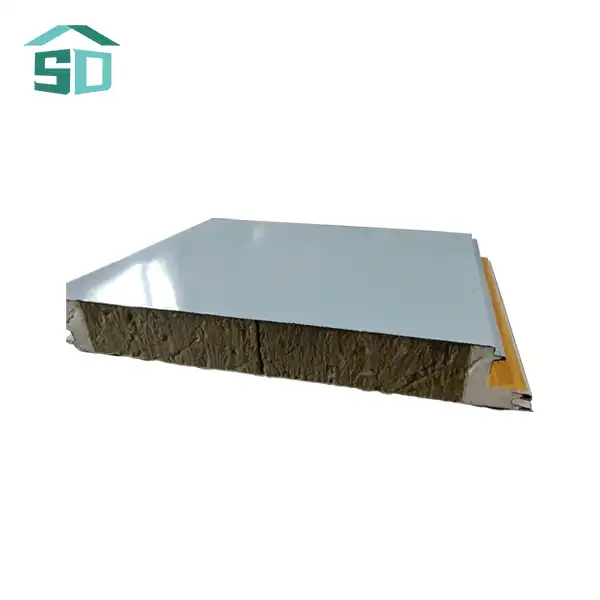

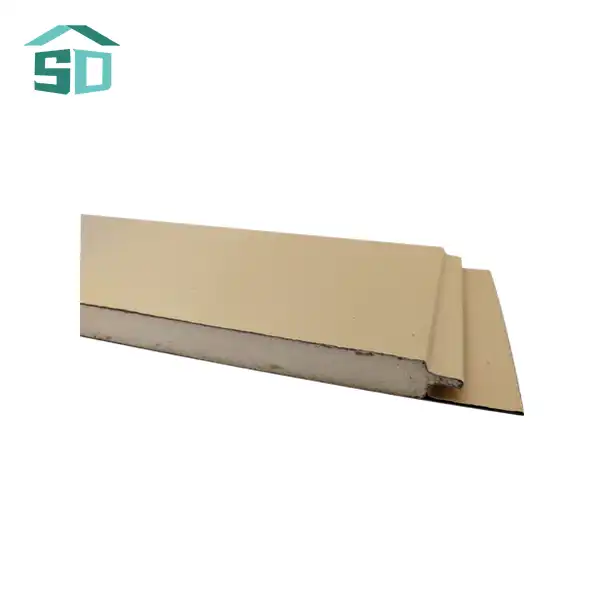

Insulated Metal Panels (IMPs)

Insulated Metal Panels (IMPs) are among the most efficient exterior wall cladding panels available. These panels consist of a foam core sandwiched between two metal facings, typically steel or aluminum. The foam core, often made of polyurethane or polyisocyanurate, provides excellent thermal insulation. IMPs can achieve R-values of up to 8 per inch, making them highly effective in reducing heat transfer. Their seamless construction also minimizes air infiltration, further enhancing their insulating properties.

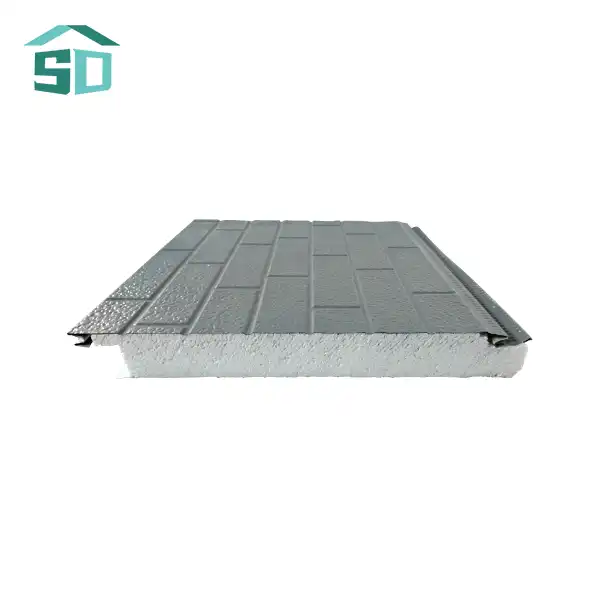

Structural Insulated Panels (SIPs)

Structural Insulated Panels (SIPs) are another top-performing option for exterior wall cladding. These panels feature a core of expanded polystyrene (EPS) or extruded polystyrene (XPS) foam insulation bonded between two layers of oriented strand board (OSB). SIPs can achieve R-values of 3.6 to 4.4 per inch, depending on the type of foam used. Their large size and prefabricated nature result in fewer joints and thermal bridges, contributing to their high insulation performance.

Vacuum Insulated Panels (VIPs)

While less common in exterior applications, Vacuum Insulated Panels (VIPs) represent the cutting edge of thermal insulation technology. These panels consist of a microporous core material encased in a thin, gas-tight envelope from which the air has been evacuated. VIPs can achieve remarkable R-values of up to 40 per inch, making them the most thermally efficient option available. However, their high cost and sensitivity to punctures limit their widespread use in exterior wall cladding applications.

Innovations in Exterior Wall Cladding Panel Insulation

The field of exterior wall cladding panels is continuously evolving, with manufacturers and researchers pushing the boundaries of thermal insulation performance. Recent innovations have led to the development of new materials and technologies that promise even greater energy efficiency and sustainability.

Aerogel-Enhanced Panels

Aerogel, often called "frozen smoke," is a synthetic ultralight material derived from a gel, where the liquid component has been replaced with gas. When incorporated into exterior wall cladding panels, aerogel can significantly boost thermal insulation performance. Some aerogel-enhanced panels can achieve R-values of up to 14 per inch, making them among the most efficient insulating materials available. These panels are particularly useful in applications where space is at a premium, as their superior insulation properties allow for thinner wall assemblies without compromising thermal performance.

Phase Change Materials (PCMs)

Phase Change Materials (PCMs) represent an innovative approach to thermal management in exterior wall cladding panels. These materials can absorb, store, and release large amounts of latent heat as they change phase from solid to liquid and back. When integrated into cladding panels, PCMs can help regulate indoor temperatures by absorbing excess heat during the day and releasing it at night, effectively reducing the load on heating and cooling systems. While PCMs don't necessarily increase the R-value of panels, they can significantly enhance overall thermal performance and energy efficiency.

Smart Insulation Systems

The integration of smart technologies into exterior wall cladding panels is opening up new possibilities for dynamic thermal insulation. These systems use sensors and actuators to adjust the insulation properties of the panels in response to changing environmental conditions. For example, some smart panels can modify their thermal conductivity based on temperature differentials, optimizing energy efficiency throughout the day and across seasons. While still in the early stages of development, smart insulation systems hold great promise for maximizing the thermal performance of exterior wall cladding panels.

Conclusion

In the quest for superior thermal insulation, exterior wall cladding panels have emerged as frontrunners in building envelope design. Insulated Metal Panels (IMPs) and Structural Insulated Panels (SIPs) consistently deliver high R-values, making them top choices for energy-efficient construction. Innovative technologies like aerogel-enhanced panels, Phase Change Materials, and smart insulation systems are pushing the boundaries of thermal performance even further. As the industry continues to evolve, we can expect to see even more advanced exterior wall cladding panel solutions that combine exceptional insulation with sustainability and aesthetic appeal.

At Weifang Sandong Building Materials Co., Ltd., we're committed to providing cutting-edge exterior wall cladding panel solutions that meet the highest standards of thermal insulation and energy efficiency. Our range of products includes state-of-the-art panels designed to maximize thermal performance while offering durability, versatility, and aesthetic appeal. Whether you're working on a new construction project or retrofitting an existing building, our expert team can help you choose the ideal exterior wall cladding panels to meet your specific needs. To learn more about our products and how they can enhance your building's thermal insulation, contact us at info@sdqsc.com.

FAQs

What is the average R-value of exterior wall cladding panels?

The R-value of exterior wall cladding panels can vary widely, typically ranging from R-3 to R-40 per inch, depending on the type and composition of the panel.

How long do insulated exterior wall cladding panels last?

High-quality insulated exterior wall cladding panels can last 30-50 years or more with proper installation and maintenance.

Can exterior wall cladding panels be used for both new construction and retrofits?

Yes, many exterior wall cladding panels are versatile enough to be used in both new construction projects and retrofitting existing buildings.

Are there eco-friendly options for insulated exterior wall cladding panels?

Yes, many manufacturers offer eco-friendly options using recycled materials or sustainable production processes. Always check with your exterior wall cladding panel manufacturer for specific eco-friendly options.

References

1. Berardi, U., & Naldi, M. (2017). The impact of the temperature dependent thermal conductivity of insulating materials on the effective building envelope performance. Energy and Buildings, 144, 262-275.

2. Kosny, J., & Kossecka, E. (2002). Multi-dimensional heat transfer through complex building envelope assemblies in hourly energy simulation programs. Energy and Buildings, 34(5), 445-454.

3. Papadopoulos, A. M. (2005). State of the art in thermal insulation materials and aims for future developments. Energy and Buildings, 37(1), 77-86.

4. Schiavoni, S., D׳Alessandro, F., Bianchi, F., & Asdrubali, F. (2016). Insulation materials for the building sector: A review and comparative analysis. Renewable and Sustainable Energy Reviews, 62, 988-1011.

5. Theodosiou, T. G., & Papadopoulos, A. M. (2008). The impact of thermal bridges on the energy demand of buildings with double brick wall constructions. Energy and Buildings, 40(11), 2083-2089.