Understanding the Fundamentals of Prefabricated Thermal Panels

Composition and Structure of Prefabricated Thermal Panels

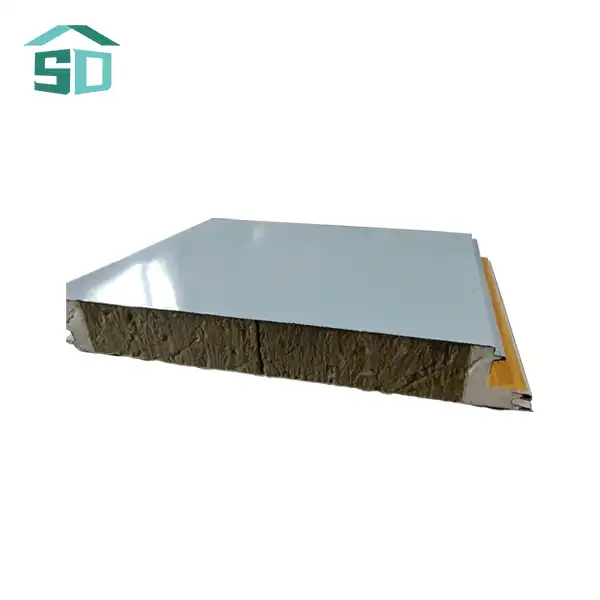

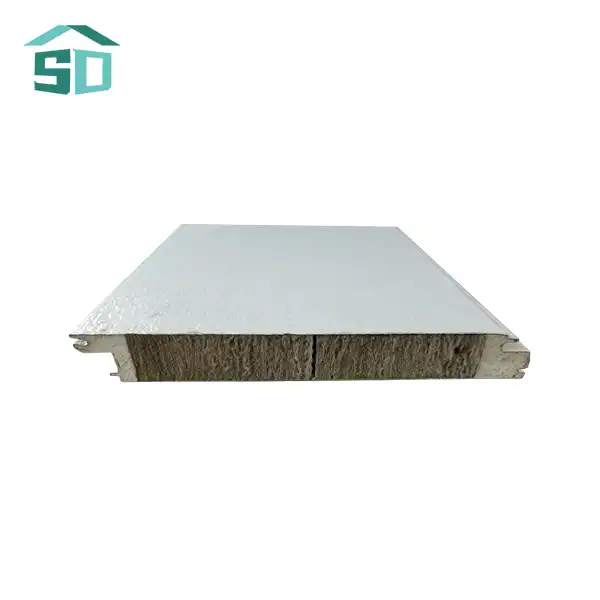

Prefabricated thermal panels are innovative building components designed to provide superior insulation and streamline construction processes. These panels typically consist of three main layers: an exterior facing, an insulation core, and an interior facing. The exterior and interior facings are often made of durable materials such as steel, aluminum, or fiber-reinforced polymers, while the core is composed of high-performance insulation materials like polyurethane foam, expanded polystyrene, or mineral wool.

The unique sandwich structure of prefabricated thermal panels allows for exceptional thermal resistance and structural integrity. The insulation core is carefully bonded to the facing materials, creating a cohesive unit that can withstand various environmental stresses while maintaining its insulative properties. This design also enables prefabricated thermal panels to be lightweight yet robust, facilitating easier handling and installation on construction sites.

Thermal Performance Characteristics

The thermal performance of prefabricated thermal panels is a key factor in their design and application. These panels are engineered to minimize heat transfer between the interior and exterior environments, contributing to energy-efficient buildings. The insulation core plays a pivotal role in achieving high R-values, which measure the panel's resistance to heat flow. Higher R-values indicate better insulation performance, resulting in reduced energy consumption for heating and cooling.

Prefabricated thermal panels suppliers often offer a range of insulation thicknesses and materials to cater to different climate zones and building requirements. For instance, panels with polyurethane foam cores typically provide excellent thermal resistance with minimal thickness, making them ideal for projects where space is at a premium. The continuous insulation provided by these panels also helps eliminate thermal bridges, which are common weak points in traditional construction methods.

Acoustic Insulation Properties

While thermal performance is often the primary focus, the acoustic insulation properties of prefabricated thermal panels are increasingly recognized as crucial for creating comfortable living and working spaces. The ability of these panels to reduce sound transmission depends on several factors, including the density and composition of the insulation core, the mass of the facing materials, and the overall panel thickness.

Many prefabricated thermal panels offer significant sound reduction capabilities, measured in terms of Sound Transmission Class (STC) ratings. Higher STC ratings indicate better sound insulation performance. The layered structure of these panels naturally lends itself to sound dampening, as the different materials and air gaps within the panel help to absorb and dissipate sound waves. Some prefabricated thermal panels suppliers offer specialized acoustic versions that incorporate additional sound-absorbing materials or structural modifications to enhance their noise reduction properties.

Balancing Thermal and Acoustic Priorities in Panel Design

Assessing Project-Specific Requirements

When designing prefabricated thermal panels, it's essential to carefully assess the specific requirements of each project. Factors such as building type, location, climate, and intended use play crucial roles in determining the optimal balance between thermal and acoustic priorities. For instance, a residential building in a noisy urban environment may require a greater emphasis on acoustic insulation, while a commercial cold storage facility would prioritize thermal performance.

Prefabricated thermal panels suppliers often work closely with architects and engineers to tailor panel designs to meet these diverse needs. This collaborative approach ensures that the final product delivers the right combination of thermal efficiency and sound insulation for the project at hand. It's also important to consider local building codes and energy efficiency standards, which may dictate minimum requirements for both thermal and acoustic performance.

Innovative Materials and Technologies

The ongoing development of new materials and technologies is expanding the possibilities for prefabricated thermal panels, allowing for improved performance in both thermal and acoustic domains. Advanced insulation materials, such as aerogels and vacuum insulated panels (VIPs), offer exceptional thermal resistance with minimal thickness, potentially freeing up space for enhanced acoustic treatments.

Some prefabricated thermal panels suppliers are incorporating phase change materials (PCMs) into their designs, which can absorb and release heat to help regulate indoor temperatures more effectively. On the acoustic front, innovations like micro-perforated facings and resonant cavity designs are being utilized to enhance sound absorption across a wider range of frequencies. These advancements allow for more versatile prefabricated thermal panels that can excel in both thermal and acoustic performance without significant compromises.

Cost-Benefit Analysis of Performance Enhancements

While striving for optimal thermal and acoustic performance is important, it's equally crucial to consider the cost implications of various design choices. Enhancing both thermal and acoustic properties simultaneously can lead to increased material and production costs, potentially impacting the overall project budget. Prefabricated thermal panels suppliers must work with clients to find the right balance between performance and cost-effectiveness.

A thorough cost-benefit analysis should take into account not only the initial investment but also long-term savings in energy costs and potential improvements in occupant comfort and productivity. For example, investing in high-performance prefabricated thermal panels with superior acoustic properties may lead to reduced HVAC requirements and lower noise-related complaints in office environments, ultimately justifying the higher upfront costs.

Applications and Case Studies

Residential Applications

In residential construction, prefabricated thermal panels offer numerous advantages, including improved energy efficiency, faster build times, and enhanced comfort for occupants. These panels are particularly well-suited for modern, energy-efficient homes that aim to minimize heating and cooling costs while providing a quiet, comfortable living environment. For example, a recent project in a suburban area utilized prefabricated thermal panels with a polyurethane core and specialized acoustic facings to achieve both high thermal resistance and excellent sound insulation from nearby traffic noise.

Prefabricated thermal panels suppliers are increasingly offering customizable options for residential applications, allowing homeowners and builders to select panels that match specific architectural styles while maintaining high performance standards. This flexibility has led to the adoption of prefabricated thermal panels in various housing types, from single-family homes to multi-story apartment buildings.

Commercial and Industrial Uses

The versatility of prefabricated thermal panels makes them ideal for a wide range of commercial and industrial applications. In office buildings, these panels can help create energy-efficient envelopes that also contribute to improved acoustic environments, enhancing worker productivity. Industrial facilities, such as warehouses and manufacturing plants, benefit from the panels' ability to maintain stable indoor temperatures while reducing noise transmission from machinery and equipment.

One notable example is a recently completed data center project that utilized high-performance prefabricated thermal panels to meet strict temperature control requirements while also mitigating noise from server equipment. The panels' excellent thermal properties helped minimize cooling costs, while their acoustic insulation capabilities ensured that noise levels remained within acceptable limits for nearby office spaces.

Specialized Applications: Cold Storage and Sound Studios

Prefabricated thermal panels find specialized applications in environments with extreme temperature or acoustic requirements. Cold storage facilities, for instance, rely heavily on the superior thermal insulation properties of these panels to maintain consistent low temperatures while minimizing energy consumption. The tight seals and continuous insulation provided by prefabricated thermal panels are crucial in preventing thermal bridging and moisture infiltration in these critical environments.

Sound studios and recording facilities represent another specialized application where the acoustic properties of prefabricated thermal panels are paramount. In these settings, panels are often custom-designed to provide optimal sound isolation and absorption across a wide frequency range. Some prefabricated thermal panels suppliers offer specialized acoustic panels that incorporate multiple layers of sound-absorbing materials, diffusers, and resonators to create ideal acoustic environments for recording and production.

Conclusion

Balancing acoustic and thermal priorities in prefabricated thermal panels design is a complex yet crucial aspect of modern construction. By carefully considering project requirements, leveraging innovative materials, and conducting thorough cost-benefit analyses, builders and designers can achieve optimal performance in both areas. The versatility of prefabricated thermal panels makes them suitable for a wide range of applications, from residential to specialized industrial settings. As technology advances, we can expect even more sophisticated solutions that seamlessly integrate thermal and acoustic performance.

Are you looking for prefabricated thermal panels that offer the perfect balance of thermal efficiency and acoustic performance? Look no further than Weifang Sandong Building Materials Co., Ltd. Our expert team is ready to help you find the ideal solution for your next project. With our customizable options, robust construction, and commitment to quality, we ensure that your building needs are met with precision and care. Contact us today at info@sdqsc.com to discover how our prefabricated thermal panels can elevate your construction project to new heights of efficiency and comfort.

FAQ

What are the main benefits of using prefabricated thermal panels?

Prefabricated thermal panels offer excellent thermal insulation, improved energy efficiency, faster installation times, and potential for enhanced acoustic performance. They are versatile, durable, and can be customized to meet specific project requirements.

How do prefabricated thermal panels compare to traditional insulation methods?

Prefabricated thermal panels generally provide superior insulation with less thickness, reduce thermal bridging, and offer faster installation compared to traditional methods. They also integrate multiple functions into a single product, streamlining the construction process.

Can prefabricated thermal panels be used in both new construction and renovation projects?

Yes, these panels are suitable for both new builds and renovations. Their modular nature and ease of installation make them an excellent choice for a wide range of construction projects.

References

1.Building Science Corporation. (2021). "Thermal and Acoustic Performance of Insulated Panels."

2.National Institute of Building Sciences. (2022). "Whole Building Design Guide: Building Envelope Design Guide."

3.International Journal of Acoustics and Vibration. (2020). "Acoustic Performance of Prefabricated Building Elements." Vol. 25, Issue 2, pp. 231-242.

4.Energy and Buildings Journal. (2021). "Comparative Analysis of Thermal Insulation Materials for Buildings." Vol. 233, 110692.

5.American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE). (2021). "ASHRAE Handbook—Fundamentals." Atlanta: ASHRAE.