Understanding Prefabricated Thermal Panel Standards

Thermal Performance Standards for Prefabricated Thermal Panels

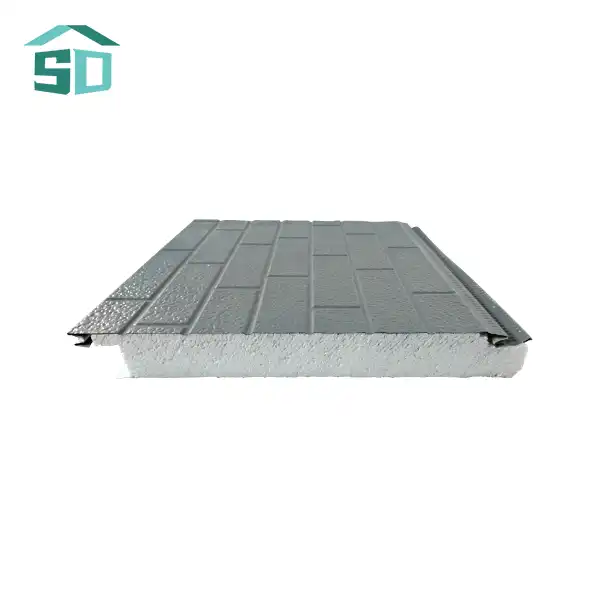

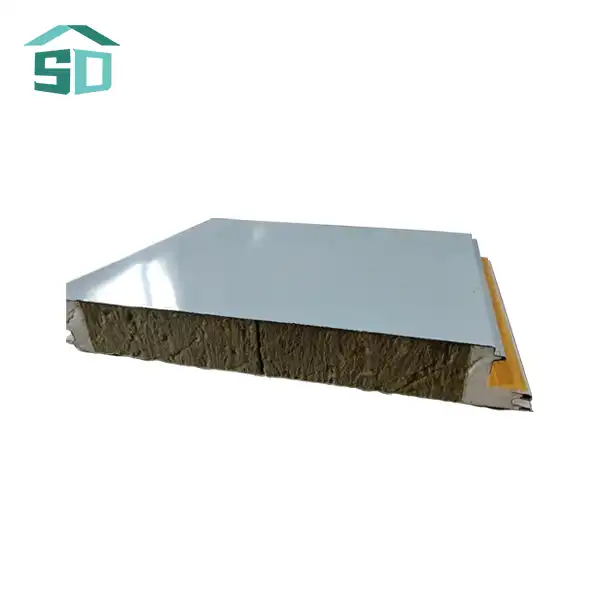

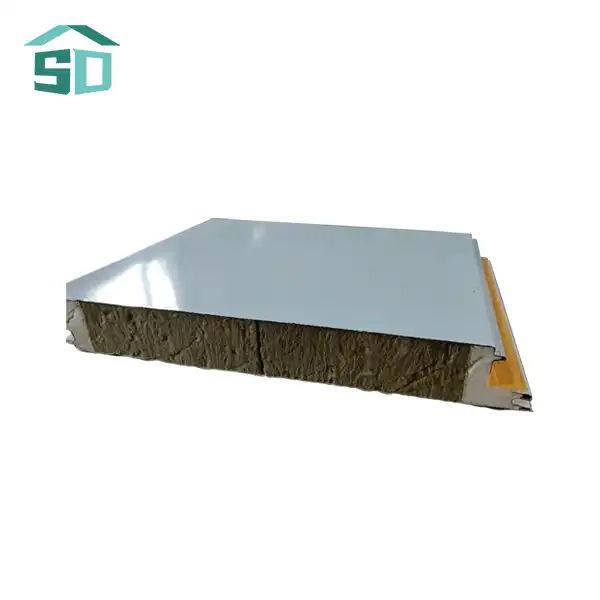

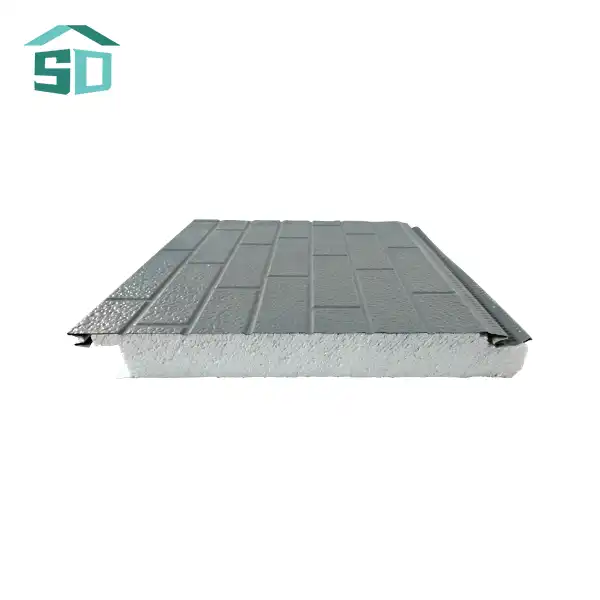

Prefabricated thermal panels are subject to stringent thermal performance standards to ensure their efficacy in various climatic conditions. The ASTM C518 standard, which measures steady-state thermal transmission properties by means of the heat flow meter apparatus, is particularly relevant. This standard helps quantify the R-value of prefabricated thermal panels, a crucial metric that indicates the panel's resistance to heat flow.

Another important standard is ASTM C1363, which outlines the method for thermal performance testing of building assemblies using a hot box apparatus. This standard is essential for evaluating the overall thermal efficiency of prefabricated thermal panels when integrated into building systems. Manufacturers often use these standards to validate their products' insulation capabilities and to provide accurate performance data to architects and builders.

Fire Safety Standards for Prefabricated Thermal Panels

Fire safety is a paramount concern in construction, and prefabricated thermal panels must adhere to strict fire resistance standards. The ASTM E84 standard, also known as the Surface Burning Characteristics of Building Materials test, is widely used to evaluate the flame spread and smoke development indices of prefabricated thermal panels. This test provides crucial information about how quickly fire might spread across the surface of the panel and the amount of smoke it would generate.

Additionally, NFPA 285 is a standard fire test method for evaluating fire propagation characteristics of exterior wall assemblies containing combustible components. This test is particularly relevant for products used in exterior applications, ensuring that they meet the necessary fire safety requirements for multi-story buildings.

Structural and Durability Standards for Prefabricated Thermal Panels

Prefabricated thermal panels must also meet various structural and durability standards to ensure long-term performance and safety. ASTM E72 provides standard test methods for conducting strength tests of panels for building construction. This standard helps evaluate the load-bearing capacity and structural integrity of prefabricated thermal panels under different stress conditions.

For panels used in exterior applications, ASTM E331 is crucial. This standard test method for water penetration of exterior windows, skylights, doors, and curtain walls by uniform static air pressure difference helps ensure that it can effectively resist water infiltration, maintaining their insulation properties and structural integrity over time.

Environmental and Sustainability Standards for Prefabricated Thermal Panels

Energy Efficiency Standards for Prefabricated Thermal Panels

Energy efficiency is a key focus in modern construction, and prefabricated thermal panels play a significant role in achieving energy-efficient buildings. The International Energy Conservation Code (IECC) provides guidelines for minimum R-values in different climate zones, which directly impacts the design and manufacture of prefabricated thermal panels. These panels must meet or exceed these requirements to be considered compliant for use in energy-efficient building designs.

Furthermore, the ENERGY STAR program, while not a standard per se, provides specifications for energy-efficient building products. Many manufacturers of prefabricated thermal panels strive to meet ENERGY STAR requirements, as it's a widely recognized symbol of energy efficiency among consumers and professionals alike.

Sustainable Material Standards for Prefabricated Thermal Panels

As sustainability becomes increasingly important in construction, prefabricated thermal panels are also subject to standards related to sustainable materials and practices. The LEED (Leadership in Energy and Environmental Design) rating system, developed by the U.S. Green Building Council, includes criteria for materials and resources used in construction. Prefabricated thermal panels can contribute to LEED credits through factors such as recycled content, regional materials, and low-emitting materials.

Additionally, the Cradle to Cradle Certified™ Product Standard evaluates products across five categories of human and environmental health. Some manufacturers of products pursue this certification to demonstrate their commitment to sustainable production practices and material selection.

Indoor Air Quality Standards for Prefabricated Thermal Panels

Indoor air quality is a critical consideration in building design, and prefabricated thermal panels must adhere to standards that ensure they don't negatively impact the indoor environment. ASTM D5116 provides guidelines for small-scale environmental chamber determinations of organic emissions from indoor materials/products. This standard is particularly relevant for evaluating the potential off-gassing of volatile organic compounds (VOCs) from prefabricated thermal panels.

The GREENGUARD Certification program, administered by UL Environment, sets standards for low-emitting products and materials. Many manufacturers of prefabricated thermal panels seek GREENGUARD certification to demonstrate that their products meet strict chemical emissions limits, contributing to healthier indoor environments.

Quality Control and Manufacturing Standards for Prefabricated Thermal Panels

Manufacturing Process Standards for Prefabricated Thermal Panels

The manufacturing of prefabricated thermal panels is governed by various quality control standards to ensure consistency and reliability. ISO 9001, the international standard for quality management systems, is widely adopted by manufacturers of prefabricated thermal panels. This standard provides a framework for ensuring that products consistently meet customer and regulatory requirements.

For panels with metal facings, standards like ASTM A653 for steel sheet, zinc-coated (galvanized) or zinc-iron alloy-coated (galvannealed) by the hot-dip process are crucial. These standards ensure the durability and corrosion resistance of the metal components in prefabricated thermal panels.

Testing and Certification Standards for Prefabricated Thermal Panels

Rigorous testing and certification processes are essential to verify that prefabricated thermal panels meet the required standards. The International Accreditation Service (IAS) provides accreditation for testing laboratories and inspection agencies, ensuring that the tests performed on prefabricated thermal panels are reliable and consistent.

Additionally, many countries have their own certification programs for building products. For instance, in the United States, the ICC Evaluation Service (ICC-ES) provides technical evaluations of building products, components, methods, and materials. Manufacturers of prefabricated thermal panels often seek ICC-ES evaluation reports to demonstrate compliance with building codes and standards.

Installation Standards for Prefabricated Thermal Panels

While not directly related to manufacturing, installation standards are crucial for ensuring that prefabricated thermal panels perform as intended. The Metal Building Manufacturers Association (MBMA) provides guidelines for the proper installation of insulated metal panels, which include many types of prefabricated thermal panels. These guidelines cover aspects such as panel alignment, fastening methods, and sealing techniques.

Furthermore, ASTM E2357, Standard Test Method for Determining Air Leakage of Air Barrier Assemblies, is relevant for evaluating the effectiveness of prefabricated thermal panels as part of an overall air barrier system. Proper installation according to manufacturer specifications and industry standards is essential to achieve the intended thermal performance and air tightness.

Conclusion

Prefabricated thermal panels are subject to a comprehensive set of standards that ensure their performance, safety, and sustainability. From thermal efficiency and fire resistance to environmental impact and manufacturing quality, these standards provide a framework for producing high-quality, reliable panels. As building technologies evolve, these standards continue to adapt, driving innovation and improvement in the prefabricated panel industry. For architects, builders, and property owners, understanding these standards is crucial for making informed decisions about building materials and ensuring compliance with building codes and regulations.

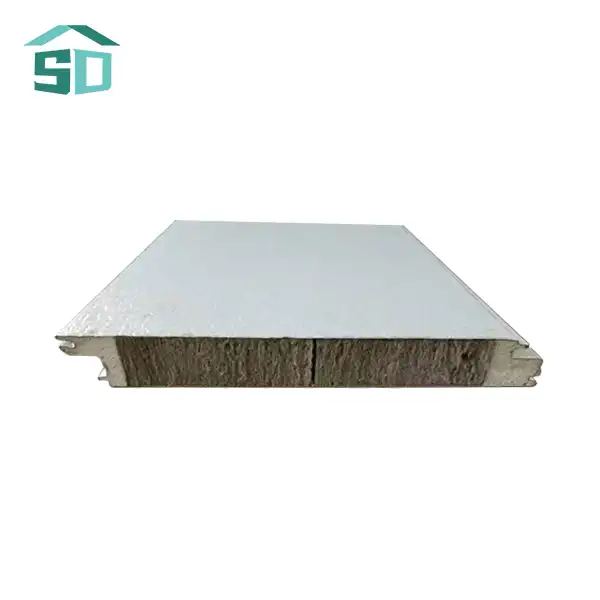

At Weifang Sandong Building Materials Co., Ltd., we pride ourselves on being a leading prefabricated thermal panels supplier. Our panels not only meet but often exceed these rigorous standards, offering superior insulation, durability, and design flexibility. Whether you're working on a residential, commercial, or industrial project, our products can provide the perfect balance of performance and aesthetics. Ready to elevate your next construction project? Contact us at info@sdqsc.com to learn more about our innovative prefabricated thermal panel solutions.

FAQs

What are the main benefits of using prefabricated thermal panels?

Prefabricated thermal panels offer excellent insulation, quick installation, design flexibility, and durability. They can significantly improve energy efficiency and reduce construction time.

How do prefabricated thermal panels contribute to sustainable construction?

These panels can contribute to LEED certification, reduce energy consumption, and often incorporate recycled materials, supporting sustainable building practices.

Are prefabricated thermal panels suitable for all climate types?

Yes, these panels can be customized to suit various climate conditions, from hot and humid to cold and dry environments.

How long do prefabricated thermal panels typically last?

With proper installation and maintenance, prefabricated thermal panels can last for several decades, often matching or exceeding the lifespan of traditional construction materials.

Can prefabricated thermal panels be used for both new construction and renovation projects?

Absolutely! These versatile panels are suitable for both new builds and retrofitting existing structures, offering improved insulation and aesthetics in both scenarios.

References

1.ASTM International. (2021). ASTM E84-21a Standard Test Method for Surface Burning Characteristics of Building Materials.

2.ASTM International. (2021). ASTM C518-21 Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus.

3.International Code Council. (2021). International Energy Conservation Code (IECC).

4.U.S. Green Building Council. (2021). LEED (Leadership in Energy and Environmental Design) Rating System.

5.International Organization for Standardization. (2015). ISO 9001:2015 Quality Management Systems - Requirements.

6.Metal Building Manufacturers Association. (2021). Metal Building Systems Manual.

7.ASTM International. (2019). ASTM E2357-18 Standard Test Method for Determining Air Leakage of Air Barrier Assemblies.