Comprehending Fire Resistance in PU Insulated Sandwich Panels

The Composition of PU Insulated Sandwich Panels

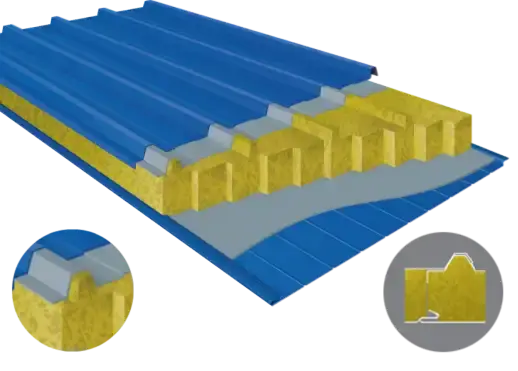

PU insulated sandwich panels are composite materials consisting of three main components: two outer facing layers and an insulating core. The outer layers are typically made of metal, such as steel or aluminum, while the core is composed of polyurethane (PU) foam. This unique structure provides excellent thermal insulation properties, making PU insulated sandwich panels a popular choice in construction projects.

The polyurethane core is the primary concern when it comes to fire resistance. Standard PU foam is combustible and can contribute to the spread of fire if not properly treated. However, advancements in material science have led to the development of fire-resistant PU formulations that significantly enhance the overall fire performance of these panels.

Fire Behavior of PU Insulated Sandwich Panels

Understanding how PU insulated sandwich panels behave in fire conditions is crucial for developing effective fire resistance strategies. When exposed to high temperatures, the PU core begins to decompose, releasing flammable gases. If these gases ignite, they can contribute to the rapid spread of fire within a building.

However, modern PU insulated sandwich panels are designed to mitigate these risks. The metal facings act as a barrier, slowing the heat transfer to the core and delaying its decomposition. Additionally, fire-retardant additives in the PU foam can suppress flame spread and reduce smoke generation.

Importance of Fire Resistance in Building Materials

Fire resistance is a critical factor in building design and material selection. It directly impacts occupant safety, property protection, and compliance with building codes and regulations. In the event of a fire, properly designed fire-resistant materials can:

- Slow the spread of flames

- Reduce smoke generation

- Maintain structural integrity for a longer period

- Provide valuable time for evacuation and firefighting efforts

For PU insulated sandwich panels, ensuring adequate fire resistance is particularly important due to their widespread use in various building types, including residential, commercial, and industrial structures. As a PU insulated sandwich panels supplier, Weifang Sandong Building Materials Co., Ltd. recognizes the significance of fire safety and implements rigorous measures to enhance the fire performance of our products.

Strategies for Enhancing Fire Resistance in PU Insulated Sandwich Panels

Fire-Retardant Additives in PU Foam

One of the primary methods for improving fire resistance in PU insulated sandwich panels is the incorporation of fire-retardant additives into the polyurethane foam core. These additives work through various mechanisms to suppress flame spread and reduce the release of flammable gases during a fire event.

Common fire-retardant additives used in PU foam include:

- Halogenated compounds: These interfere with the combustion process by trapping free radicals

- Phosphorus-based additives: These promote char formation, creating a protective layer that inhibits further burning

- Inorganic fillers: Materials like alumina trihydrate or magnesium hydroxide release water vapor when heated, cooling the surrounding area

The selection and concentration of these additives are carefully balanced to maintain the insulation properties of the PU foam while significantly enhancing its fire resistance. As a leading PU insulated sandwich panels supplier, we invest heavily in research and development to optimize these formulations.

Fire-Resistant Coatings for Panel Surfaces

The outer facings of PU insulated sandwich panels play a crucial role in fire resistance. Applying specialized fire-resistant coatings to these surfaces can further enhance their performance in fire conditions. These coatings are designed to:

- Slow heat transfer to the panel core

- Form an insulating char layer when exposed to high temperatures

- Reduce surface flame spread

- Maintain structural integrity for extended periods

Modern fire-resistant coatings are often intumescent, meaning they expand and form a protective char layer when exposed to heat. This expansion can increase the coating thickness by up to 50 times, providing an effective thermal barrier.

Incorporation of Fire-Resistant Barriers

Another effective strategy for enhancing fire resistance in PU insulated sandwich panels is the incorporation of fire-resistant barriers within the panel structure. These barriers can be placed between the PU core and the outer facings or as intermediate layers within the core itself.

Common materials used for fire-resistant barriers include:

- Mineral wool

- Fiberglass

- Ceramic fibers

- Fire-resistant polymers

These barriers serve multiple purposes in improving fire performance:

- They act as a physical barrier to flame spread

- They provide additional thermal insulation, slowing heat transfer

- Some materials, like mineral wool, are inherently non-combustible

- They can help maintain the panel's structural integrity during a fire event

By strategically incorporating these barriers, PU insulated sandwich panels can achieve significantly improved fire resistance ratings without compromising their overall performance or increasing thickness substantially.

Testing and Certification for Fire-Resistant PU Insulated Sandwich Panels

Fire Resistance Testing Procedures

Rigorous testing is essential to ensure the fire resistance of PU insulated sandwich panels meets required standards. These tests simulate real-world fire conditions and evaluate various aspects of panel performance. Common fire resistance tests for sandwich panels include:

- Small-scale tests: These evaluate the ignitability, flame spread, and heat release rate of panel materials

- Large-scale tests: These assess the overall fire performance of assembled panel systems

- Furnace tests: These determine the fire resistance rating by exposing panels to standardized time-temperature curves

Specific test procedures may vary depending on regional standards and intended applications. For example, the EN 13501-1 standard is widely used in Europe, while ASTM E84 and NFPA 285 are common in North America.

As a reputable PU insulated sandwich panels supplier, we ensure our products undergo comprehensive testing to verify their fire resistance properties. This commitment to quality and safety is a cornerstone of our manufacturing process.

International Fire Safety Standards for Sandwich Panels

PU insulated sandwich panels must comply with various international fire safety standards to be used in construction projects. These standards set benchmarks for fire performance and guide manufacturers in developing fire-resistant products. Some key international standards include:

- EN 13501: European standard for fire classification of construction products and building elements

- ASTM E84: Standard Test Method for Surface Burning Characteristics of Building Materials (USA)

- BS 476: British Standard for fire tests on building materials and structures

- ISO 13784: International standard for reaction-to-fire tests for sandwich panel building systems

Compliance with these standards often involves achieving specific ratings for factors such as flame spread, smoke development, and fire resistance duration. As regulations evolve, PU insulated sandwich panels suppliers must stay abreast of changes and continuously improve their products to meet or exceed these standards.

Certification and Quality Assurance Processes

To ensure consistent fire resistance performance, PU insulated sandwich panels undergo rigorous certification and quality assurance processes. These processes typically involve:

- Initial type testing: Comprehensive testing of panel designs to establish baseline performance

- Factory production control: Ongoing monitoring of manufacturing processes to maintain quality

- Regular third-party audits: Independent verification of product performance and manufacturing standards

- Continuous product development: Research and improvement of fire resistance properties

Certification from recognized bodies provides assurance to architects, builders, and end-users that PU insulated sandwich panels meet required fire safety standards. Common certifications include:

- CE marking for products sold in the European Economic Area

- UL (Underwriters Laboratories) certification in North America

- FM (Factory Mutual) Approvals for industrial and commercial applications

At Weifang Sandong Building Materials Co., Ltd., we maintain stringent quality control measures throughout our production process. Our state-of-the-art facilities are equipped with advanced testing equipment to ensure every PU insulated sandwich panel meets the highest fire resistance standards before leaving our factory.

Conclusion

Ensuring fire resistance in PU insulated sandwich panels is a multifaceted approach that combines innovative material science, advanced manufacturing techniques, and rigorous testing protocols. By incorporating fire-retardant additives, applying specialized coatings, and integrating fire-resistant barriers, these panels can provide excellent thermal insulation while maintaining high levels of fire safety. Adherence to international standards and ongoing quality assurance processes are crucial in delivering reliable, fire-resistant building materials.

If you're seeking high-quality, fire-resistant PU insulated sandwich panels for your next construction project, look no further than Weifang Sandong Building Materials Co., Ltd. Our commitment to safety, innovation, and quality ensures that our products meet the most stringent fire resistance requirements. Contact us today at info@sdqsc.com to learn more about our range of exterior cladding and facade solutions, including our advanced PU insulated sandwich panels.

FAQs

What makes PU insulated sandwich panels fire-resistant?

PU insulated sandwich panels achieve fire resistance through a combination of fire-retardant additives in the foam core, specialized coatings on the panel surfaces, and the incorporation of fire-resistant barriers. These elements work together to slow flame spread, reduce smoke generation, and maintain structural integrity during fire events.

How are fire-resistant PU insulated sandwich panels tested?

These panels undergo various tests, including small-scale material tests, large-scale system tests, and furnace tests that simulate real-world fire conditions. These tests evaluate factors such as ignitability, flame spread, heat release rate, and overall fire resistance duration.

Are fire-resistant PU insulated sandwich panels suitable for all building types?

While fire-resistant PU insulated sandwich panels are versatile, their suitability depends on specific building codes and regulations. They are commonly used in residential, commercial, and industrial structures, but it's essential to consult with local authorities and fire safety experts for your particular application.

References

1. European Committee for Standardization. (2018). EN 13501-1: Fire classification of construction products and building elements.

2. ASTM International. (2021). ASTM E84: Standard Test Method for Surface Burning Characteristics of Building Materials.

3. International Organization for Standardization. (2018). ISO 13784: Reaction-to-fire tests for sandwich panel building systems.

4. Mouritz, A. P., & Gibson, A. G. (2006). Fire Properties of Polymer Composite Materials. Springer Science & Business Media.

5. National Fire Protection Association. (2019). NFPA 285: Standard Fire Test Method for Evaluation of Fire Propagation Characteristics of Exterior Wall Assemblies Containing Combustible Components.