Understanding Sandwich Panels and Their Insulation Properties

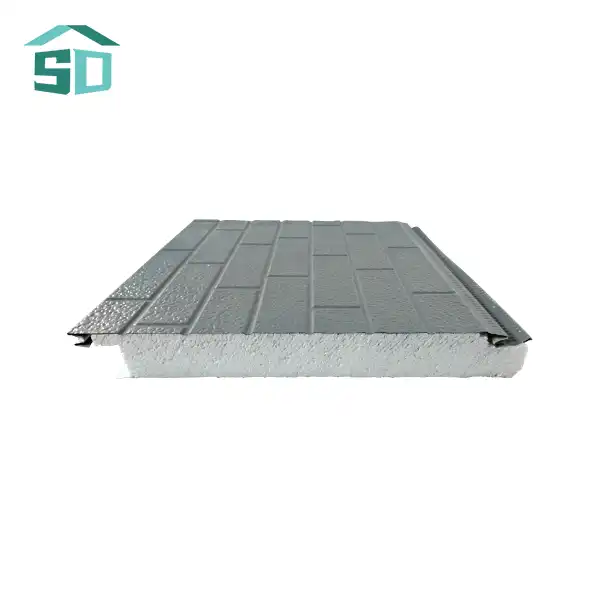

Sandwich panels represent a revolutionary building material that combines structural strength with superior insulation capabilities. These panels consist of two outer layers, typically made of metal or other durable materials, sandwiching a core of insulating material. The insulation core is often composed of materials like polyurethane (PUR), polyisocyanurate (PIR), or expanded polystyrene (EPS), each offering unique thermal properties.

The thermal performance of sandwich panels is primarily determined by the thickness and composition of the insulating core. As the thickness increases, so does the panel's ability to resist heat transfer, measured by its R-value. The 10 cm sandwich panel, with its substantial core thickness, provides an impressive level of thermal insulation that meets or exceeds many building code requirements.

Thermal Resistance and R-Value of 10 cm Sandwich Panels

The R-value of a 10 cm sandwich panel varies depending on the specific insulation material used in the core. Generally, a 10 cm panel with a PUR or PIR core can achieve an R-value between 5.0 and 6.0 m²K/W. This level of thermal resistance is sufficient to significantly reduce heat loss in winter and heat gain in summer, contributing to improved energy efficiency and indoor comfort.

To put this in perspective, many building codes require minimum R-values of around 3.5-4.0 m²K/W for walls in residential construction. The 10 cm sandwich panel comfortably exceeds these standards, making it a popular choice for both residential and commercial applications.

Comparative Analysis: 10 cm vs Other Thicknesses

While thicker sandwich panels (e.g., 15 cm or 20 cm) offer even higher R-values, the 10 cm thickness often represents an optimal balance between insulation performance and practical considerations. Thicker panels can be more challenging to handle and install, and may require modifications to standard framing systems. They also come with higher material costs.

On the other hand, thinner panels (e.g., 5 cm or 8 cm) may not provide sufficient insulation for many climate zones, potentially leading to increased energy costs over time. The 10 cm sandwich panel offers a "sweet spot" that satisfies insulation requirements while remaining cost-effective and easy to work with.

Applications and Benefits of 10 cm Sandwich Panels

The versatility of 10 cm sandwich panels makes them suitable for a wide range of construction applications. These panels excel in both new construction and retrofit projects, offering benefits that extend beyond mere insulation.

Ideal Uses in Construction

10 cm sandwich panels find application in various parts of building envelopes:

- Exterior Walls: The panels provide excellent thermal insulation while also serving as a weather barrier.

- Roofing: Sandwich panels can create well-insulated, lightweight roofing systems.

- Interior Partitions: In industrial or commercial settings, these panels can create insulated dividers between spaces with different temperature requirements.

- Cold Storage Facilities: The high insulation value makes 10 cm panels ideal for maintaining low temperatures in storage areas.

Energy Efficiency and Cost Savings

The superior insulation properties of 10 cm sandwich panels translate directly into energy savings. By reducing heat transfer through the building envelope, these panels minimize the workload on heating and cooling systems. This results in lower energy consumption and reduced utility costs over the life of the building.

Moreover, the energy efficiency provided by 10 cm sandwich panels can contribute to a building's green certification, potentially increasing its market value and appeal to environmentally conscious tenants or buyers.

Structural Advantages and Ease of Installation

Beyond their insulation properties, 10 cm sandwich panels offer several structural and practical advantages:

- Lightweight Construction: Despite their thickness, these panels are relatively light, reducing the load on the building's structural framework.

- Rapid Installation: The prefabricated nature of sandwich panels allows for quick and efficient installation, reducing overall construction time.

- Structural Integrity: The composite structure of sandwich panels provides excellent strength-to-weight ratio, contributing to the overall stability of the building.

- Reduced Thermal Bridging: The continuous insulation layer minimizes thermal bridges, enhancing overall energy performance.

Considerations for Choosing 10 cm Sandwich Panels

While 10 cm sandwich panels offer numerous benefits, several factors should be considered when deciding on their use in a construction project.

Climate and Local Building Codes

The suitability of 10 cm sandwich panels can vary depending on the local climate and building regulations. In regions with extreme temperatures, thicker panels might be necessary to meet insulation requirements. It's crucial to consult local building codes and energy efficiency standards to ensure compliance.

Cost-Benefit Analysis

While 10 cm sandwich panels may have a higher upfront cost compared to traditional insulation methods, their long-term benefits often justify the investment. A comprehensive cost-benefit analysis should consider factors such as:

- Energy savings over the building's lifetime

- Reduced construction time and labor costs

- Potential increase in property value due to energy efficiency

- Reduced maintenance and replacement costs compared to traditional insulation systems

Aesthetic Considerations and Customization Options

10 cm sandwich panels are available in a variety of finishes and colors, allowing for customization to suit different architectural styles. However, the thickness of the panel may influence the overall appearance of the building, particularly in terms of wall depth at openings like windows and doors. Architects and designers should consider these aesthetic implications when incorporating 10 cm panels into their designs.

Conclusion

The 10 cm sandwich panel emerges as a versatile and effective insulation solution for modern construction projects. Its balance of thermal performance, structural benefits, and practical advantages make it an attractive option for a wide range of applications. While thicker or thinner panels may be more suitable in specific scenarios, the 10 cm thickness often represents an optimal compromise between insulation efficiency and cost-effectiveness. As building energy efficiency standards continue to evolve, the role of high-performance materials like 10 cm sandwich panels in creating sustainable, comfortable, and energy-efficient buildings is likely to grow.

At Weifang Sandong Building Materials Co., Ltd., we specialize in manufacturing high-quality sandwich panels, including the versatile 10 cm option. Our commitment to innovation, sustainability, and customer satisfaction drives us to produce insulation solutions that meet the evolving needs of the construction industry. Whether you're planning a residential, commercial, or industrial project, our 10 cm sandwich panels can help you achieve your energy efficiency and building performance goals. For more information about our products or to discuss your specific needs, please contact us at info@sdqsc.com.

FAQs

How does the insulation performance of a 10 cm sandwich panel compare to traditional insulation methods?

10 cm sandwich panels generally offer superior insulation performance compared to many traditional methods, providing high R-values in a compact, easy-to-install package.

Are 10 cm sandwich panels suitable for all climate zones?

While 10 cm panels are suitable for many climates, extreme cold or hot regions may require thicker panels. Always consult local building codes and energy efficiency standards.

Can 10 cm sandwich panels be used in residential construction?

Yes, these panels are suitable for both residential and commercial construction, offering excellent insulation and energy efficiency benefits for homes.

References

1.American Society of Heating, Refrigerating and Air-Conditioning Engineers. (2017). ASHRAE Handbook - Fundamentals. Atlanta, GA: ASHRAE.

2.International Code Council. (2018). International Energy Conservation Code. Country Club Hills, IL: ICC.

3.U.S. Department of Energy. (2015). Insulation Materials. Energy Saver.

4.European Committee for Standardization. (2017). EN 14509: Self-supporting double skin metal faced insulating panels - Factory made products - Specifications. Brussels: CEN.