Pre-Installation Planning and Preparation Errors

Successful sandwich panel installation begins long before the first panel is placed. Meticulous planning and preparation are essential to avoid costly mistakes and ensure a smooth installation process. Let's explore some common pre-installation errors and how to prevent them.

Inadequate Site Assessment

One of the most critical pre-installation steps is a thorough site assessment. Failing to evaluate the site conditions can lead to numerous complications during and after installation. Key factors to consider include:

- Terrain and soil conditions

- Climate and weather patterns

- Existing structures and obstacles

- Accessibility for equipment and materials

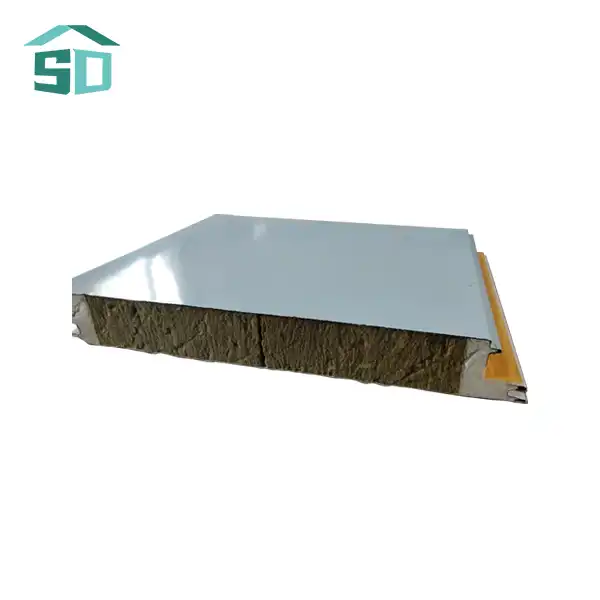

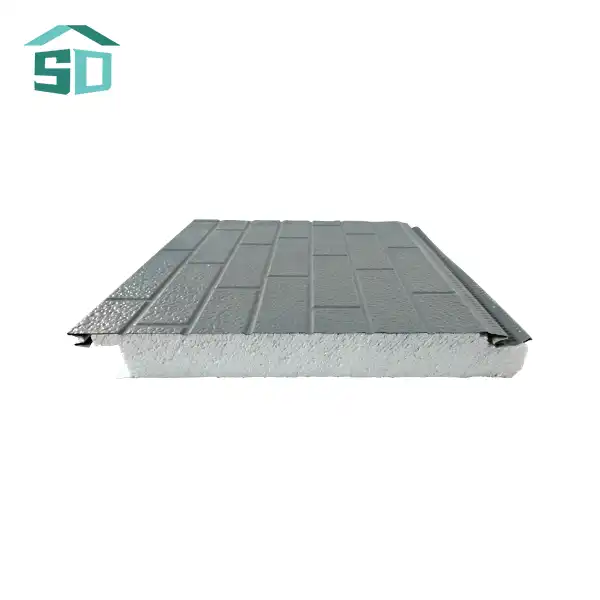

Neglecting these factors can result in improper panel selection, installation delays, and potential structural issues. To avoid this mistake, conduct a comprehensive site survey and consult with experts to ensure your 10 cm sandwich panelsare suitable for the specific location and conditions.

Incorrect Panel Specification

Choosing the wrong type or size of sandwich panels can have far-reaching consequences. Common specification errors include:

- Selecting panels with inadequate insulation properties

- Opting for panels that don't meet local building codes

- Underestimating load-bearing requirements

- Failing to consider aesthetic factors

To avoid these issues, work closely with manufacturers and architects to determine the most appropriate panel specifications for your project. Consider factors such as thermal performance, fire resistance, structural requirements, and design aesthetics.

Inadequate Tool and Equipment Preparation

Having the right tools and equipment is crucial for efficient and accurate sandwich panel installation. Common mistakes in this area include:

- Using incorrect cutting tools, leading to panel damage

- Lack of proper lifting and handling equipment

- Insufficient safety gear for workers

- Inadequate storage facilities for panels before installation

To address these issues, create a comprehensive checklist of required tools and equipment well in advance of the installation date. Ensure all items are in good working condition and that your team is trained in their proper use.

Installation Process Missteps

The actual installation of sandwich panels requires precision and attention to detail. Even minor errors during this phase can lead to significant problems down the line. Let's examine some common installation mistakes and how to avoid them.

Improper Panel Alignment

Correct alignment is crucial for the structural integrity and aesthetic appeal of sandwich panel installations. Misalignment can lead to:

- Gaps between panels, compromising insulation

- Uneven surfaces, affecting the overall appearance

- Increased stress on fasteners and joints

- Water infiltration and potential damage

To ensure proper alignment, use laser levels and alignment tools. Start from a fixed reference point and regularly check for plumbness and levelness throughout the installation process.

Incorrect Fastening Techniques

The method and quality of fastening can significantly impact the performance and longevity of sandwich panel installations. Common fastening errors include:

- Over-tightening screws, causing panel deformation

- Under-tightening fasteners, leading to loose panels

- Using incompatible or low-quality fasteners

- Incorrect spacing of fasteners

To avoid these issues, follow manufacturer guidelines for fastener type, size, and spacing. Use torque-controlled tools to ensure consistent tightening, and regularly inspect fasteners during installation.

Inadequate Sealing and Weatherproofing

Proper sealing is essential to maintain the insulation properties and weather resistance of10 cm sandwich panels. Common sealing mistakes include:

- Using incompatible or low-quality sealants

- Failing to clean surfaces before applying sealants

- Inadequate application of sealants at joints and penetrations

- Neglecting to install proper flashing and weather barriers

To ensure effective sealing, use manufacturer-recommended sealants and follow proper application techniques. Pay special attention to joints, corners, and any penetrations in the panels.

Post-Installation Oversights

The work doesn't end once the sandwich panels are in place. Proper post-installation care and maintenance are crucial for ensuring long-term performance and durability. Let's explore some common post-installation mistakes and how to avoid them.

Neglecting Final Inspections

Failing to conduct thorough post-installation inspections can lead to overlooked issues that may become serious problems later. Key areas to inspect include:

- Panel alignment and levelness

- Fastener tightness and placement

- Sealant application and coverage

- Overall structural integrity

To avoid this mistake, develop a comprehensive inspection checklist and ensure it's followed meticulously. Consider engaging third-party inspectors for an unbiased assessment.

Inadequate Protection During Finishing Work

10 cm sandwich panels can be damaged during subsequent construction activities if not properly protected. Common oversights include:

- Failing to cover panels during painting or plastering

- Allowing heavy equipment or materials to rest against panels

- Neglecting to protect panels from chemical spills or construction debris

To prevent damage, implement protective measures such as temporary coverings and establish clear guidelines for other trades working around the installed panels.

Lack of Proper Maintenance Planning

While sandwich panels are known for their low maintenance requirements, neglecting basic care can shorten their lifespan. Common maintenance oversights include:

- Failing to establish a regular cleaning schedule

- Neglecting to inspect and reseal joints periodically

- Ignoring minor damage or wear that could lead to larger issues

- Failing to educate building occupants on proper care

To ensure long-term performance, develop a comprehensive maintenance plan that includes regular inspections, cleaning, and preventive measures. Provide clear guidelines to building owners or facility managers on proper care and maintenance procedures.

Conclusion

Avoiding sandwich panel installation mistakes is crucial for maximizing the benefits of this versatile building material. From meticulous pre-installation planning to careful execution and thorough post-installation care, each phase of the process requires attention to detail and adherence to best practices. By understanding and avoiding common pitfalls in panel specification, alignment, fastening, sealing, and maintenance, you can ensure your sandwich panel installation delivers optimal performance, energy efficiency, and longevity.

At Weifang Sandong Building Materials Co., Ltd., we're committed to helping you achieve the best results with our high-quality 10 cm sandwich panels. Our products are designed for easy installation and long-lasting performance, backed by comprehensive support and guidance. Whether you're planning a new construction project or a renovation, our expert team is here to assist you every step of the way. For more information on our sandwich panels and how to ensure a flawless installation, contact us at info@sdqsc.com.

FAQs

How often should sandwich panels be inspected after installation?

It's recommended to conduct visual inspections annually and more thorough assessments every 3-5 years, depending on environmental conditions and usage.

Can sandwich panels be repaired if damaged?

Minor damage can often be repaired, but significant damage may require panel replacement. Consult with the manufacturer or a qualified professional for specific repair guidance.

Are special tools required for sandwich panel installation?

While many standard construction tools can be used, some specialized tools for cutting and fastening may be required. Always refer to the manufacturer's guidelines for specific tool recommendations.

References

1.Smith, J. (2022). Modern Construction Techniques: Sandwich Panel Applications. Journal of Building Engineering, 45, 103-115.

2.Johnson, A. et al. (2021). Best Practices in Sandwich Panel Installation. Construction and Building Materials, 302, 124-138.

3.Brown, R. (2023). Energy Efficiency in Building Envelopes: The Role of Sandwich Panels. Sustainable Cities and Society, 86, 103-114.

4.Davis, M. (2022). Preventing Common Errors in Modular Construction. International Journal of Construction Management, 22(8), 1456-1470.

5.Wilson, E. (2023). Long-term Performance of Sandwich Panels in Various Climates. Building and Environment, 228, 109-121.