Types of Metal Siding Panels for Sheds

When it comes to metal siding panels for sheds, there are several options available, each with its own unique characteristics and benefits. Understanding these different types will help you make an informed decision based on your specific needs and preferences.

Corrugated Metal Panels

Corrugated metal panels are a popular choice for shed siding due to their strength and versatility. These panels feature a wavy, rippled pattern that adds structural integrity and enhances water runoff. Corrugated panels are typically made from galvanized steel or aluminum and come in various gauges, with thicker gauges offering increased durability. They are relatively easy to install and provide excellent protection against the elements.

Standing Seam Panels

Standing seam metal panels are known for their sleek, modern appearance and superior weather resistance. These panels feature raised seams that interlock, creating a watertight barrier. Standing seam panels are often made from steel or aluminum and come in a variety of colors and finishes. While they tend to be more expensive than corrugated panels, they offer enhanced durability and a more polished look for your shed.

Ribbed Metal Panels

Ribbed metal panels are similar to corrugated panels but feature a more subtle, linear pattern. These panels offer a balance between strength and aesthetics, making them a popular choice for both residential and commercial applications. Ribbed panels are available in various materials, including steel and aluminum, and can be customized with different rib spacing and depths to achieve the desired look for your shed.

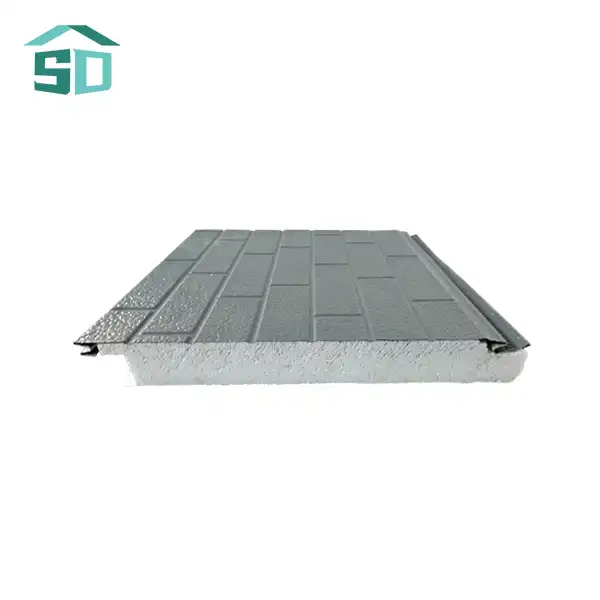

Board and Batten Metal Panels

Board and batten metal panels mimic the traditional wood siding style but offer the durability and low maintenance of metal. These panels feature wide, flat sections (boards) alternating with narrow, raised sections (battens). This style provides a charming, rustic look while still benefiting from the longevity and weather resistance of metal siding. Board and batten metal panels are an excellent choice for those seeking a more traditional aesthetic for their shed.

Factors to Consider When Choosing Metal Siding Panels for Your Shed

Selecting the right metal siding panels for your shed involves considering various factors to ensure you get the best fit for your needs and budget. Here are some key aspects to keep in mind during the decision-making process:

Climate and Weather Conditions

The climate in your area plays a crucial role in determining the most suitable metal siding panels for your shed. Consider factors such as temperature fluctuations, humidity levels, and exposure to harsh weather conditions like heavy rain, snow, or strong winds. For example, if you live in a coastal area with high humidity and salt exposure, aluminum panels might be a better choice due to their corrosion resistance. In areas with extreme temperature changes, steel panels with proper insulation can provide better thermal performance.

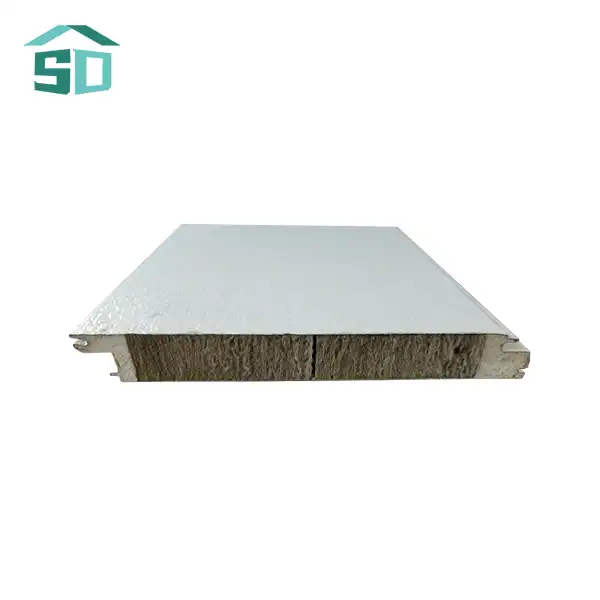

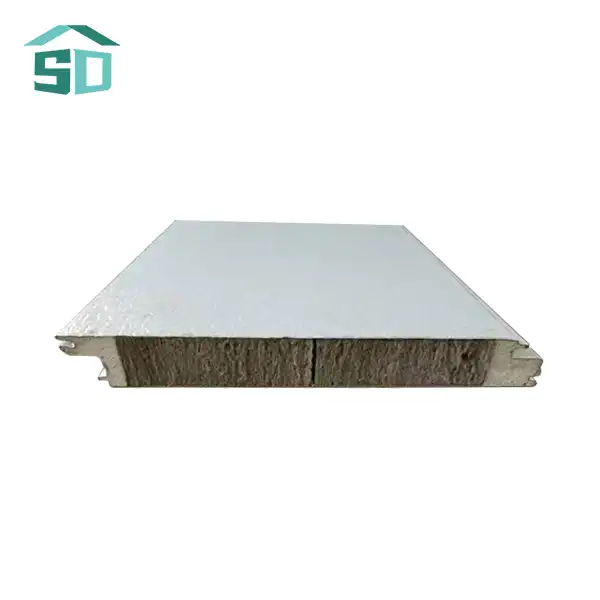

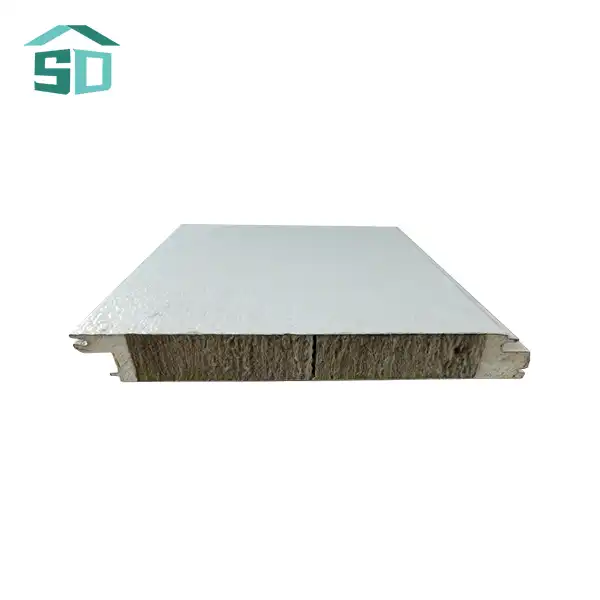

Durability and Longevity

One of the primary advantages of metal siding panels is their durability. However, different types of metal and finishes offer varying levels of longevity. Galvanized steel panels are known for their strength and resistance to rust, while aluminum panels excel in corrosion resistance. Consider the gauge of the metal as well; thicker gauges generally offer increased durability but come at a higher cost. Look for panels with high-quality protective coatings that can extend the lifespan of your shed siding.

Aesthetic Appeal and Design Options

Metal siding panels come in a wide range of colors, textures, and finishes, allowing you to customize the appearance of your shed. Consider how the chosen panels will complement your home's exterior and overall landscape. Some metal siding options can mimic the look of wood or other materials, providing versatility in design. Keep in mind that darker colors may absorb more heat, which could affect the interior temperature of your shed.

Maintenance Requirements

While metal siding panels generally require less maintenance than wood or vinyl alternatives, some options may need more attention than others. Consider the level of maintenance you're willing to undertake and choose panels that align with your preferences. For example, smooth-surfaced panels may be easier to clean, while textured panels might hide minor imperfections better but require more effort to keep clean.

Cost and Budget Considerations

The cost of metal siding panels can vary significantly based on the material, gauge, finish, and brand. While it's tempting to opt for the least expensive option, consider the long-term value and potential savings in maintenance and replacement costs. Higher-quality panels may have a higher upfront cost but can offer better durability and longevity, potentially saving you money in the long run.

Installation Complexity

If you're planning a DIY installation, consider the complexity of the installation process for different types of metal siding panels. Some options, like corrugated panels, are relatively straightforward to install, while others, such as standing seam panels, may require more specialized skills and tools. Factor in the cost of professional installation if the chosen panels are beyond your DIY capabilities.

Installation and Maintenance of Metal Siding Panels for Sheds

Proper installation and maintenance of metal siding panels are crucial for ensuring their longevity and optimal performance. Here's a guide to help you navigate the installation process and maintain your shed's metal siding:

Preparing for Installation

Before installing metal siding panels on your shed, it's essential to properly prepare the surface. Start by inspecting the shed's structure for any damage or rot, and make necessary repairs. Ensure the surface is clean, dry, and free from debris. Install a weather barrier or house wrap to provide an additional layer of protection against moisture. If required, add insulation to improve the shed's thermal performance.

Installation Process

The specific installation process may vary depending on the type of metal siding panels you've chosen. However, here are some general steps to follow:

- Begin at the bottom of the wall and work your way up, ensuring each panel overlaps the one below it.

- Use appropriate fasteners, such as screws with neoprene washers, to secure the panels. Follow the manufacturer's recommendations for spacing and placement of fasteners.

- Cut panels as needed to fit around windows, doors, and corners. Use proper safety equipment and tools designed for cutting metal.

- Install trim pieces around openings and at corners for a finished look and added protection against water infiltration.

- Seal any gaps or joints with a high-quality sealant compatible with the metal siding material.

If you're not confident in your DIY skills, it's advisable to hire a professional installer to ensure proper installation and maximize the performance of your metal siding panels.

Maintenance Tips

While metal siding panels are known for their low maintenance requirements, some regular care can help extend their lifespan and keep them looking their best:

- Clean the panels annually using a soft brush or cloth and a mild detergent solution. Avoid using abrasive materials or harsh chemicals that could damage the protective coating.

- Inspect the siding regularly for any signs of damage, such as dents, scratches, or loose panels. Address any issues promptly to prevent further damage.

- Check and re-seal any joints or seams that may have degraded over time to maintain the watertight integrity of the siding.

- Trim back any vegetation that may be in contact with the metal siding to prevent moisture retention and potential damage.

- If your metal siding panels have a painted finish, consider repainting every 10-15 years or as recommended by the manufacturer to maintain their appearance and protective properties.

By following these installation and maintenance guidelines, you can ensure that your metal siding panels provide long-lasting protection and aesthetic appeal for your shed.

Conclusion

Metal siding panels offer a durable, versatile, and attractive solution for protecting and enhancing the appearance of your shed. By considering factors such as climate, durability, aesthetics, maintenance requirements, and budget, you can select the ideal metal siding panels that best suit your needs. Proper installation and regular maintenance will ensure that your chosen panels provide long-lasting performance and visual appeal. Whether you opt for corrugated steel, standing seam aluminum, or another type of metal siding, investing in quality materials and professional installation can significantly extend the life of your shed and improve its overall value.

At Weifang Sandong Building Materials Co., Ltd., we are committed to providing high-quality metal siding panels and innovative insulation solutions for various construction projects. Our extensive range of exterior cladding and facade solutions, including metal siding panels, is designed to meet the diverse needs of our customers while adhering to principles of sustainability and energy efficiency. For expert advice on selecting the perfect metal siding panels for your shed or to learn more about our products, please don't hesitate to contact us at info@sdqsc.com.

FAQs

What are the advantages of using metal siding panels for sheds?

Metal siding panels offer durability, low maintenance, weather resistance, and a variety of aesthetic options. They are also fire-resistant and can help improve energy efficiency.

How long do metal siding panels typically last?

With proper installation and maintenance, metal siding panels can last 40-70 years, depending on the material and environmental conditions.

Can I install metal siding panels on my shed myself?

While some types of metal siding panels are suitable for DIY installation, others may require professional expertise. It's important to assess your skills and the complexity of the installation before deciding.

Are metal siding panels energy-efficient?

Yes, metal siding panels can contribute to energy efficiency by reflecting solar heat and providing an opportunity for additional insulation during installation.

How do I maintain metal siding panels on my shed?

Regular cleaning with mild soap and water, annual inspections for damage, and prompt repairs when needed are key to maintaining metal siding panels.

References

1.Metal Construction Association. (2021). Metal Cladding - Design Guide.

2.U.S. Department of Energy. (2022). Guide to Home Insulation.

3.American Iron and Steel Institute. (2020). Steel Siding Installation Guide.

4.National Association of Home Builders. (2021). Exterior Siding Materials.

5.Environmental Protection Agency. (2022). Energy Star Program Requirements for Roof Products.