- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Which panel types best resist condensation and mold in cold rooms?

When it comes to cold room construction, insulated wall panels with closed-cell foam cores like polyurethane (PUR) or polyisocyanurate (PIR) offer superior resistance to condensation and mold growth. These panels create an effective vapor barrier, preventing moisture penetration and thermal bridging. Their non-porous structure inhibits water absorption, making them ideal for maintaining hygienic conditions in temperature-controlled environments. Additionally, metal-faced insulated panels with proper joint sealing further enhance moisture resistance, ensuring long-term protection against condensation and mold issues in cold storage facilities.

Comprehending Condensation and Mold Risks in Cold Rooms

The Science Behind Condensation Formation

Condensation occurs when warm, moist air comes into contact with a cold surface. In cold rooms, this phenomenon is particularly problematic due to the significant temperature differential between the interior and exterior environments. Insulated wall panels play a crucial role in mitigating this issue by creating a thermal barrier that minimizes the temperature gradient across the wall structure. High-quality panels with excellent thermal properties help maintain a consistent internal temperature, reducing the likelihood of condensation formation on surfaces within the cold room.

Factors Contributing to Mold Growth

Mold thrives in environments with excess moisture, organic materials, and suitable temperatures. Cold rooms are particularly susceptible to mold growth due to the potential for condensation and the presence of foodstuffs or other organic matter. Effective insulated wall panels not only prevent condensation but also create an inhospitable environment for mold spores. By maintaining a dry, controlled atmosphere, these panels significantly reduce the risk of mold proliferation, ensuring the integrity and safety of stored goods.

The Importance of Proper Insulation in Cold Storage

Insulated wall panels are the cornerstone of effective cold storage design. They not only maintain the desired low temperatures but also act as a barrier against external heat and moisture infiltration. The right insulation system helps optimize energy efficiency, reduce operational costs, and extend the lifespan of refrigeration equipment. By choosing panels with superior condensation and mold resistance properties, facility managers can ensure a hygienic, efficient, and long-lasting cold storage environment.

Characteristics of Mold-Resistant Insulated Wall Panels

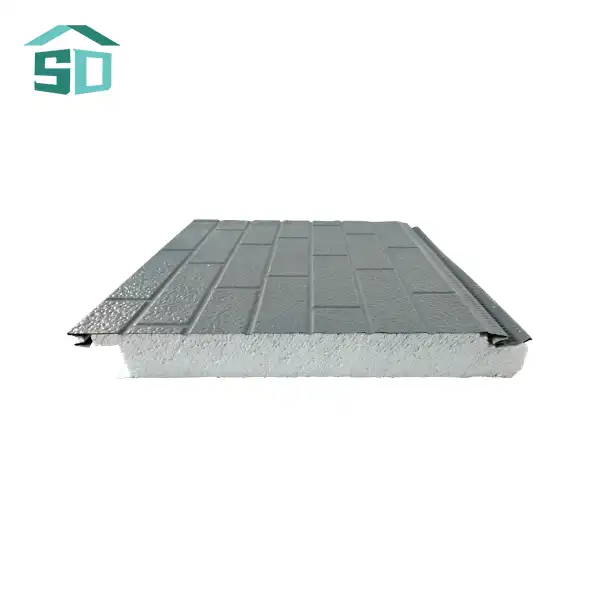

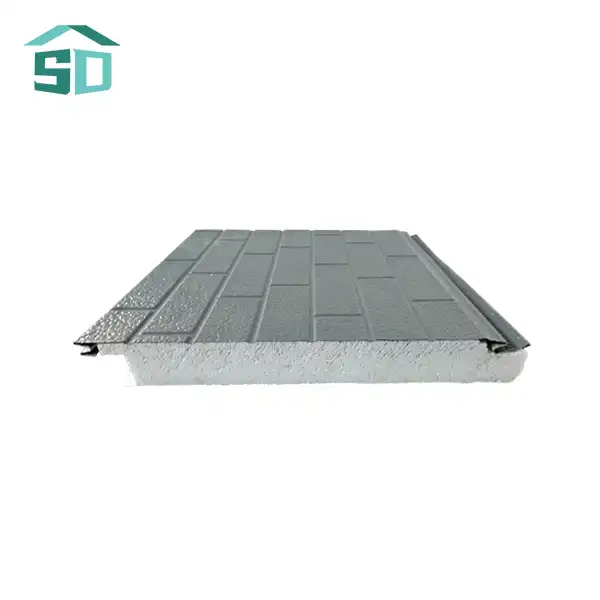

Material Composition and Core Types

The most effective insulated wall panels for resisting condensation and mold typically feature closed-cell foam cores. Polyurethane (PUR) and polyisocyanurate (PIR) are popular choices due to their excellent thermal performance and moisture resistance. These materials have a closed-cell structure that inhibits water vapor transmission and absorption. Some manufacturers also incorporate antimicrobial additives into the foam core or panel facings, providing an additional layer of protection against mold growth.

Surface Treatments and Coatings

The exterior surfaces of insulated wall panels play a crucial role in mold prevention. Many high-performance panels feature metal facings with specialized coatings that resist moisture and microbial growth. These coatings may include fluoropolymer-based finishes or other hydrophobic treatments that repel water and prevent the adhesion of mold spores. Some manufacturers also offer panels with food-grade stainless steel facings, which are particularly suitable for cold rooms in food processing and storage facilities.

Joint and Sealing Systems

The effectiveness of insulated wall panels in resisting condensation and mold is heavily dependent on the quality of their joint and sealing systems. Advanced panel designs incorporate interlocking joints with built-in vapor barriers and thermal breaks. These features prevent moisture ingress and thermal bridging at panel connections, which are common weak points in cold room construction. Some systems also utilize specialized sealants or gaskets to ensure an airtight and watertight seal between panels, further enhancing their mold-resistant properties.

Installation and Maintenance Best Practices

Proper Installation Techniques

The installation process is critical for maximizing the performance of insulated wall panels in cold room applications. Proper techniques include ensuring a clean and level substrate, using appropriate fasteners and sealants, and maintaining consistent panel alignment. It's essential to follow manufacturer guidelines for panel spacing, joint sealing, and vapor barrier continuity. Some advanced panel systems feature cam-lock mechanisms or tongue-and-groove designs that simplify installation while ensuring a tight, moisture-resistant fit. Professional installation by experienced contractors is often recommended to guarantee optimal performance.

Regular Inspection and Maintenance Routines

Even the best insulated wall panels require regular inspection and maintenance to preserve their mold-resistant properties. Facility managers should implement a routine inspection schedule to check for signs of damage, moisture intrusion, or seal degradation. This may include visual inspections, thermal imaging surveys, and moisture meter readings. Any identified issues should be promptly addressed to prevent the onset of mold growth. Regular cleaning of panel surfaces with appropriate antimicrobial solutions can also help maintain a hygienic environment and extend the life of the insulation system.

Addressing Moisture and Ventilation Challenges

While high-quality insulated wall panels provide excellent moisture resistance, it's important to address broader moisture and ventilation challenges within the cold room environment. This may include implementing proper air circulation systems, maintaining optimal humidity levels, and ensuring adequate drainage for any condensate that may form on refrigeration equipment. Some advanced cold room designs incorporate dehumidification systems or positive air pressure controls to further mitigate moisture-related issues and enhance the overall performance of the insulated wall panels.

Conclusion

In conclusion, selecting the right insulated wall panels is crucial for preventing condensation and mold growth in cold rooms. Panels with closed-cell foam cores, moisture-resistant coatings, and advanced sealing systems offer the best protection against these issues. Proper installation and regular maintenance are equally important in ensuring long-term performance. By prioritizing these factors, facility managers can create hygienic, energy-efficient cold storage environments that meet the highest standards of food safety and product preservation.

As a leading insulated wall panels manufacturer, Weifang Sandong Building Materials Co., Ltd. offers innovative solutions designed to excel in challenging cold room applications. Our panels combine cutting-edge materials with advanced manufacturing techniques to provide superior condensation and mold resistance. For expert guidance on selecting the ideal insulated wall panels for your cold storage project, don't hesitate to reach out to our team at info@sdqsc.com.

FAQ

What is the R-value of your insulated wall panels for cold rooms?

Our panels offer R-values ranging from R-20 to R-40, depending on thickness and core material. We can provide specific values for each panel type upon request.

Are your insulated wall panels suitable for food processing facilities?

Yes, we offer panels with food-grade finishes that meet strict hygiene standards for food processing and storage environments.

How long do your insulated wall panels typically last in cold room applications?

With proper installation and maintenance, our panels can last 30+ years in cold room settings. However, lifespan can vary based on specific environmental conditions.

Do you offer custom sizes for insulated wall panels?

Absolutely! We can manufacture panels to your exact specifications to ensure a perfect fit for your cold room project.

References

1.ASHRAE Handbook - Refrigeration (2018 Edition). American Society of Heating, Refrigerating and Air-Conditioning Engineers.

2.Cold Store Design and Refrigeration by Clive V. Dellino (2019). Wiley-Blackwell.

3.International Association for Cold Storage Construction (IACSC) Guidelines.

4.Journal of Food Engineering: "Insulation Materials for Cold Storage Facilities" (2020).