- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Decorative Exterior Insulation Panels: The Smart Choice for Modern Buildings

Decorative exterior insulation panels have revolutionized the construction industry, offering a perfect blend of aesthetics and functionality. These innovative building materials provide superior insulation properties while enhancing the visual appeal of any structure. By combining energy efficiency, durability, and design flexibility, decorative exterior insulation panels have become the smart choice for modern buildings. They not only improve thermal performance but also contribute to the overall sustainability and longevity of structures, making them an ideal solution for architects, builders, and property owners looking to create stylish, energy-efficient, and low-maintenance buildings.

The Evolution of Exterior Insulation: From Functional to Fabulous

The concept of exterior insulation has come a long way from its humble beginnings. Initially, the primary focus was on improving thermal performance and energy efficiency. However, as architectural trends evolved and the demand for aesthetically pleasing buildings increased, manufacturers began to explore ways to combine insulation with decorative elements.

This led to the development of decorative exterior insulation panels, which offer the best of both worlds. These panels not only provide excellent insulation properties but also serve as an attractive exterior finish. They come in a wide range of colors, textures, and patterns, allowing architects and designers to create visually stunning facades without compromising on energy efficiency.

The Science Behind Decorative Exterior Insulation Panels

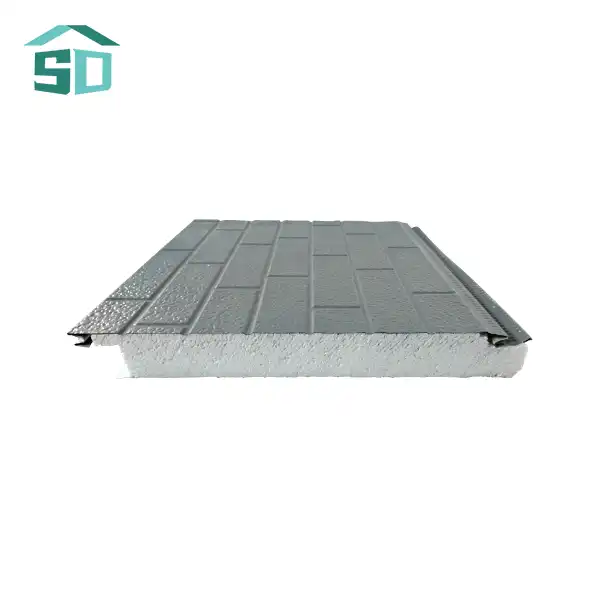

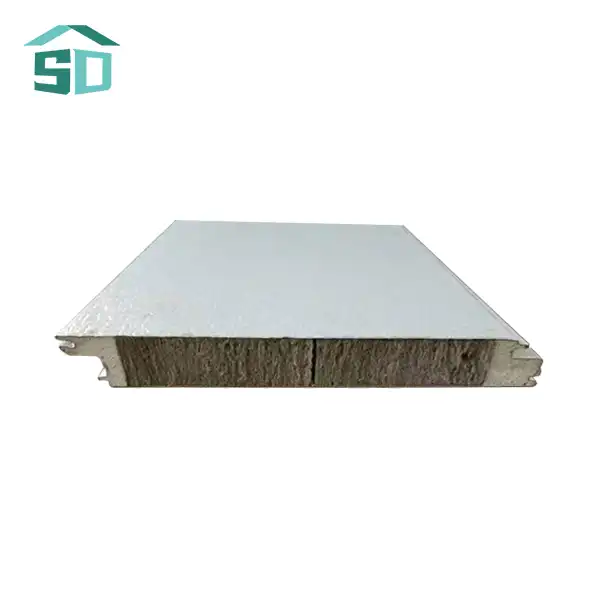

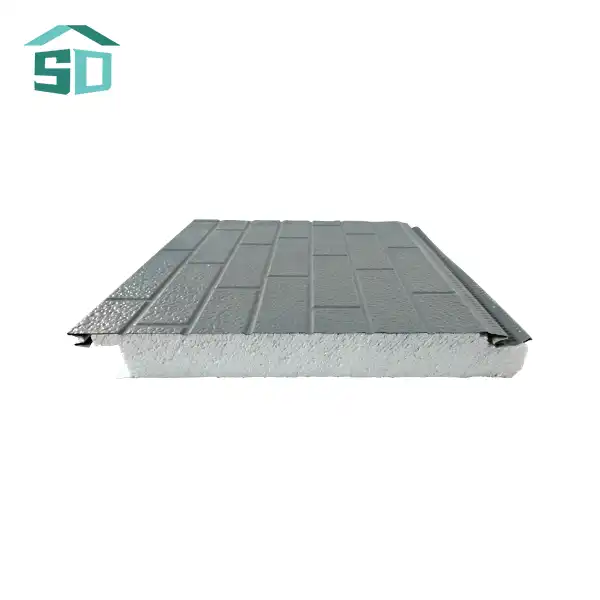

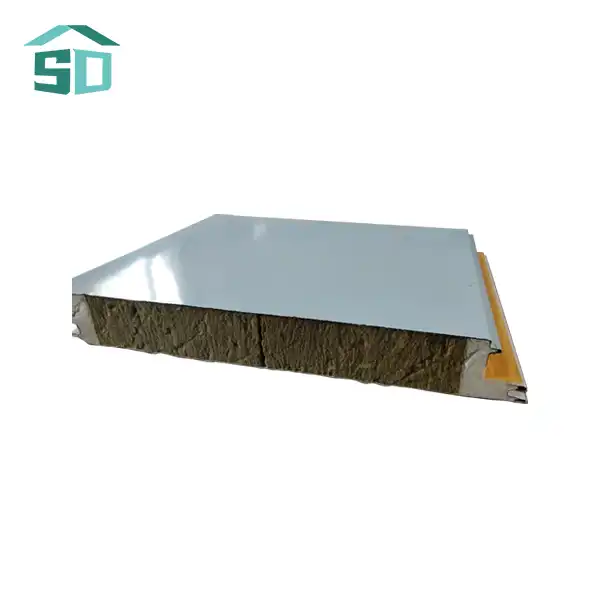

Decorative exterior insulation panels are typically composed of three main components: an outer decorative layer, an insulation core, and a backing material. The outer layer is designed to withstand weathering and provide the desired aesthetic appeal. It can be made from various materials such as metal, fiber cement, or composite materials.

The insulation core is the heart of the panel, directly influencing its thermal efficiency and overall energy performance. It is typically made from materials such as polyurethane, polystyrene, rock wool, and glass wool, all of which are specifically selected for their superior thermal resistance. By minimizing heat transfer, these cores play a crucial role in maintaining consistent indoor temperatures and reducing energy consumption.

The backing material provides the essential structural strength that supports the panel, ensuring its stability during installation and long-term use. Beyond offering rigidity, it enhances the panel's durability, helping it withstand mechanical stress, environmental conditions, and daily wear. Additionally, high-quality backing materials improve the overall performance of the panel, ensuring that it remains reliable and effective across various construction applications.

Advantages of Decorative Exterior Insulation Panels

Decorative exterior insulation panels offer numerous benefits that make them an attractive option for modern construction projects:

Energy Efficiency and Cost Savings

One of the primary advantages of decorative exterior insulation panels is their superior thermal performance. By creating a continuous insulation layer on the building's exterior, these panels significantly reduce heat transfer, leading to lower energy consumption for heating and cooling. This translates to substantial cost savings on energy bills over the lifespan of the building.

Aesthetic Versatility

Decorative exterior insulation panels come in an extensive range of colors, textures, and finishes. This versatility allows architects and designers to create unique and visually appealing facades that can complement any architectural style. From sleek modern designs to traditional looks, these panels can be customized to meet specific aesthetic requirements.

Durability and Low Maintenance

Engineered to withstand harsh weather conditions, decorative exterior insulation panels are highly durable. They resist fading, corrosion, and impact damage, ensuring that the building's exterior remains attractive for years to come. Additionally, these panels require minimal maintenance, saving time and money on upkeep.

Installation and Integration of Decorative Exterior Insulation Panels

The installation process for decorative exterior insulation panels is relatively straightforward, making them a popular choice among builders and contractors. These panels can be installed over existing walls or as part of new construction projects.

Installation Process

The installation typically involves the following steps:

1. Preparation of the wall surface

2. Installation of a vapor barrier (if required)

3. Attachment of furring strips or a mounting system

4. Placement and securing of the insulation panels

5. Application of finishing touches, such as sealants and trims

The specific installation method may vary depending on the panel type and manufacturer's recommendations. It's crucial to follow proper installation guidelines to ensure optimal performance and longevity.

Seamless Integration with Building Systems

Decorative exterior insulation panels can be seamlessly integrated with other building systems, such as windows, doors, and roofing. This integration not only enhances the overall aesthetic appeal but also improves the building's energy performance by reducing thermal bridging and air leakage.

Many manufacturers offer complementary accessories, such as corner pieces, joint sealants, and custom trims, to ensure a polished and professional finish. These accessories contribute to the overall performance and durability of the insulation system.

Conclusion

Decorative exterior insulation panels represent a significant advancement in building technology, offering a perfect balance between form and function. Their ability to enhance energy efficiency, provide aesthetic versatility, and ensure long-term durability makes them an ideal choice for modern construction projects. As the construction industry continues to evolve, these panels are likely to play an increasingly important role in creating sustainable, beautiful, and high-performing buildings.

Are you ready to transform your building's exterior while boosting its energy efficiency? Explore our range of decorative exterior insulation panels at Weifang Sandong Building Materials Co., Ltd. We offer a wide selection of stylish, durable, and high-performance panels to suit your specific needs. Contact decorative exterior insulation panelsmanufatureer today at info@sdqsc.com to learn more about how our products can enhance your next construction project.

FAQ

What materials are used in decorative exterior insulation panels?

Decorative exterior insulation panels typically use materials like aluminum, steel, stainless steel, or copper for the outer layer, with insulation cores made of polyurethane, polystyrene, rock wool, or glass wool.

How do these panels contribute to energy efficiency?

These panels provide a continuous insulation layer, reducing heat transfer and improving the building's thermal performance, which leads to lower energy consumption and costs.

Are decorative exterior insulation panels fire-resistant?

Yes, many of these panels are designed to meet stringent fire safety standards and can offer excellent fire resistance, with ratings up to Class A depending on the material.

Can these panels be customized?

Absolutely! These panels are available in various sizes, colors, and finishes, allowing for customization to fit specific project requirements and aesthetic preferences.

How long do decorative exterior insulation panels typically last?

When properly installed and maintained, these panels can last for several decades, offering long-term durability and performance.

References

1. U.S. Department of Energy. (2022). Insulation Materials. Energy.gov.

2. National Institute of Building Sciences. (2021). Whole Building Design Guide: Exterior Insulation and Finish Systems (EIFS).

3. American Society of Heating, Refrigerating and Air-Conditioning Engineers. (2021). ASHRAE Handbook - Fundamentals. ASHRAE.

4. Building Science Corporation. (2020). Info-500: Building Materials Property Table.

5. International Code Council. (2021). International Energy Conservation Code. ICC.