Residential Applications of Polyurethane Insulation Panels

In the residential sector, polyurethane insulation panels have gained significant traction due to their exceptional thermal properties and ease of installation. Homeowners and builders are increasingly turning to these panels to create more energy-efficient living spaces.

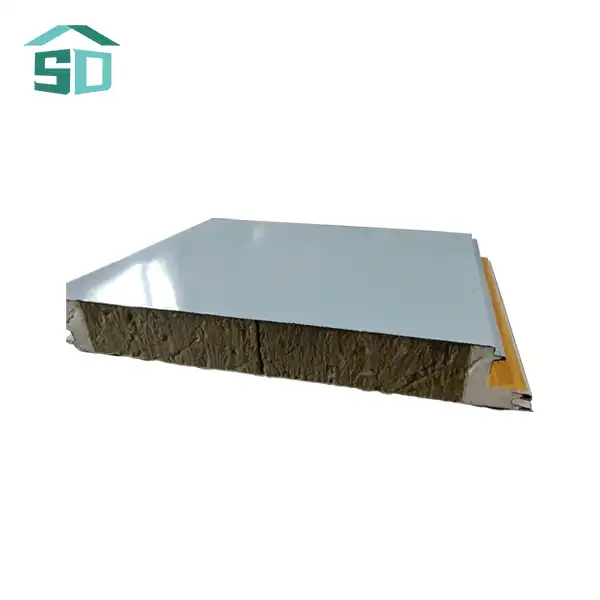

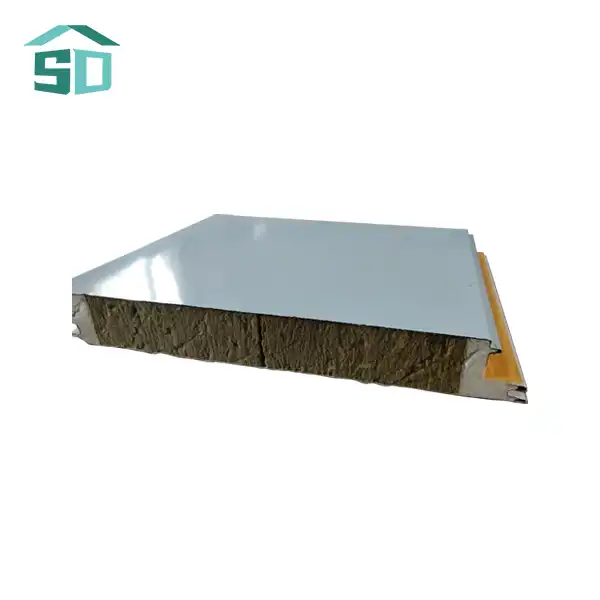

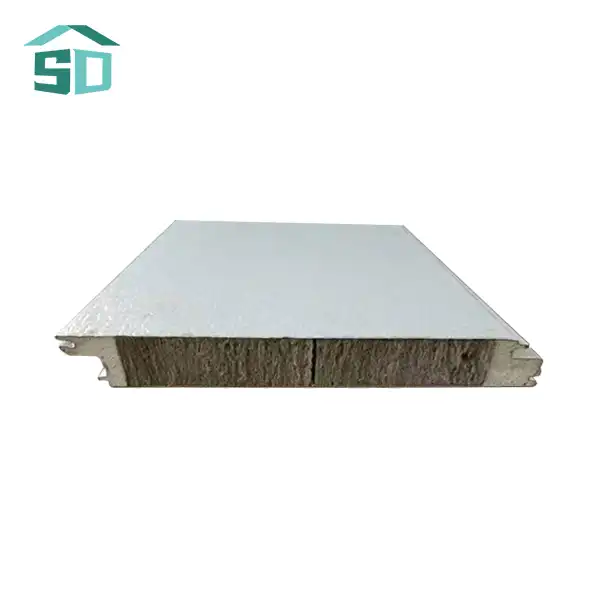

Exterior Wall Insulation

Aluminum stands out as a top choice for weather-resistant external wall cladding due to its lightweight yet exceptionally durable nature. This makes it ideal not only for new constructions but also for renovation projects. Aluminum cladding provides superior resistance to corrosion, which is especially important in coastal regions where high salt content in the air can accelerate material degradation. Additionally, its non-combustible properties enhance the overall fire safety profile of any building, making it a reliable and long-lasting option.

Roof and Attic Insulation

Steel cladding offers robust protection against harsh and severe weather conditions, making it a popular material for external walls. Known for its high strength, steel can easily withstand strong winds, heavy rainfall, and even hailstorms. Modern steel cladding often features advanced protective coatings that significantly improve its weather resistance and extend its lifespan. Moreover, steel's versatility allows it to be used in a wide range of architectural designs, from sleek, modern aesthetics to classic, traditional styles.

Basement and Foundation Insulation

Composite cladding materials provide an excellent balance of durability, appealing aesthetics, and environmental sustainability. Typically, these panels are made by combining recycled wood fibers with high-performance resins, creating a product that resists moisture, UV damage, and temperature changes effectively. Composite cladding can replicate the natural look of wood while offering much better weather resistance and requiring less maintenance. This makes it an attractive option for homeowners seeking a blend of beauty and practicality in their exterior walls.

Commercial and Industrial Uses of Polyurethane Insulation

The benefits of polyurethane insulation panels extend well beyond residential applications. Their versatility and superior performance make them a popular choice in various commercial and industrial settings.

Office Buildings and Retail Spaces

In commercial structures like office buildings and retail spaces, maintaining a comfortable indoor environment is crucial for employee productivity and customer satisfaction. Polyurethane insulation panels, available in standard sizes of 1200 x 2400 mm or custom dimensions, can be easily integrated into these buildings' envelope. Their high R-value ensures excellent thermal resistance, helping to keep interiors cool in summer and warm in winter, thereby reducing HVAC costs.

Cold Storage and Warehouses

The food and pharmaceutical industries rely heavily on temperature-controlled environments for storing perishable goods. Polyurethane insulation panels are indispensable in constructing cold storage facilities and warehouses. Their excellent thermal properties and moisture resistance help maintain consistent temperatures and humidity levels, crucial for preserving product quality. The panels' fire-resistant nature, achieving a Class B2 rating, also adds an extra layer of safety to these critical facilities.

Agricultural Buildings

Polyurethane insulation panels find extensive use in agricultural buildings such as barns, greenhouses, and livestock housing. These structures often require precise temperature and humidity control to ensure optimal conditions for animals or crops. The panels' customizable nature, with thickness options ranging from 50mm to 100mm or custom thicknesses, allows farmers to tailor the insulation to their specific needs. Additionally, the panels' durability and resistance to pests make them an ideal choice for these challenging environments.

Innovative Applications and Future Trends

As the construction industry continues to evolve, so does the application of polyurethane insulation panels. Innovative uses and emerging trends are expanding the potential of these versatile materials.

Prefabricated and Modular Construction

The rise of prefabricated and modular construction has opened new opportunities for polyurethane insulation panels, which are highly valued for their lightweight nature and ease of installation. These panels can be pre-installed directly into wall and roof modules off-site, significantly streamlining the overall building process while ensuring consistent quality and performance. This method is especially advantageous in regions with harsh climates or short construction seasons, as it reduces on-site labor, accelerates project timelines, and improves energy efficiency in completed structures.

Green Building and Sustainable Design

As sustainability becomes increasingly important in construction, polyurethane insulation panels are playing a crucial role in green building design. Their superior insulation properties contribute significantly to a building's energy efficiency, helping projects achieve certifications like LEED (Leadership in Energy and Environmental Design). Moreover, the panels' long lifespan and recyclability align with the principles of sustainable construction, reducing waste and environmental impact over time.

Retrofitting Historic Buildings

Preserving and upgrading historic buildings presents unique challenges, particularly when it comes to improving energy efficiency without altering the structure's character. Polyurethane insulation panels, with their slim profile and customizable finishes, offer a solution. They can be discreetly integrated into existing walls and roofs, dramatically improving thermal performance while maintaining the building's aesthetic integrity. This application is becoming increasingly important as cities worldwide seek to modernize their building stock without losing architectural heritage.

Conclusion

Polyurethane insulation panels have proven to be a versatile and effective solution for a wide range of insulation needs across various sectors. Their superior thermal properties, coupled with benefits like moisture resistance, fire safety, and ease of installation, make them an attractive option for both new construction and renovation projects. As the demand for energy-efficient and sustainable building solutions continues to grow, the applications for polyurethane insulation panels are likely to expand further. For those interested in learning more about these innovative insulation solutions and their potential applications, please contact us at info@sdqsc.com.