Grasping R-value and Its Importance in Insulation

R-value is a crucial metric in the world of insulation, measuring the thermal resistance of a material. In simpler terms, it indicates how well a substance can impede heat flow. The higher the R-value, the more effective the insulation. This concept is paramount when considering polyurethane insulation panels for your construction or renovation projects.

The Science Behind R-value

R-value is decided by the material's warm conductivity and thickness. Warm conductivity, indicated by the Greek letter λ (lambda), measures how effortlessly warm passes through a substance—the lower the esteem, the way better the cover execution. For polyurethane cover boards, the warm conductivity is astonishingly moo at 0.022 W/mK, which altogether contributes to their tall R-value. This amazing warm resistance makes a difference keep up comfortable indoor temperatures, diminishes vitality utilization for warming and cooling, and bolsters long-term vitality effectiveness in both private and commercial buildings.

The relationship between R-value, thickness, and thermal conductivity can be expressed as:

R-value = Thickness (in meters) / Thermal Conductivity (W/mK)

This equation elucidates why polyurethane insulation panels, with their low thermal conductivity, can achieve such high R-values even at relatively thin thicknesses.

Comparing Polyurethane to Other Insulation Materials

When compared with other common separator materials, polyurethane separator boards stand out for their predominant warm execution. For occasion, fiberglass ordinarily offers an R-value of around 2.2 to 2.7 per inch, whereas extended polystyrene (EPS) gives around 3.6 to 4 per inch. In differentiate, polyurethane gloats an noteworthy R-value of approximately 6 to 7 per inch. This clearly illustrates its warm effectiveness advantage, permitting builders and originators to accomplish the same level of separator with more slender boards, which can offer assistance spare space and move forward by and large building plan adaptability.

Factors Influencing the R-value of Polyurethane Insulation Panels

Several factors can affect the R-value of polyurethane insulation panels, understanding which can help in selecting the most appropriate product for specific insulation needs.

Density and Its Impact on R-value

The density of polyurethane foam plays a significant role in determining its R-value. Generally, higher density foams offer better insulation properties by minimizing air gaps and enhancing thermal resistance. However, there's an optimal range where this improved performance aligns with practical cost considerations. Selecting foam within this ideal density range ensures that projects benefit from excellent energy efficiency without incurring unnecessary expenses. For polyurethane insulation panels, densities typically range from 30 to 50 kg/m³, with higher densities often correlating with higher R-values.

Thickness Considerations

As specified prior, thickness straightforwardly impacts R-value. Polyurethane separator boards are accessible in different thicknesses, commonly extending from 50mm to 100mm, with custom choices accessible. A 50mm board, for occurrence, might give an R-value of roughly 15, whereas a 100mm board may offer an R-value of around 30. This adaptability permits for custom fitted arrangements to meet particular cover necessities.

Manufacturing Process and Quality Control

The manufacturing process and quality control measures significantly impact the final R-value of polyurethane insulation panels. Advanced production lines and stringent quality control systems ensure consistent foam structure and optimal thermal properties. For example, at Weifang Sandong Building Materials Co., Ltd., comprehensive inspections of product thickness, mechanical strength, and flame retardancy are conducted to maintain high-quality standards.

Maximizing Energy Efficiency with Polyurethane Insulation Panels

The high R-value of polyurethane insulation panels translates to substantial energy savings and improved building comfort. Let's explore how these panels contribute to energy efficiency and their various applications.

Energy Savings and Cost-Effectiveness

The superior insulation properties of polyurethane panels can lead to significant reductions in heating and cooling costs. By effectively minimizing heat transfer, these panels help maintain stable indoor temperatures, reducing the load on HVAC systems. Over time, the energy savings can offset the initial investment, making polyurethane insulation panels a cost-effective choice for long-term building efficiency. Additionally, their consistent performance across varying climates ensures reliable thermal comfort year-round, further enhancing their value in modern construction projects.

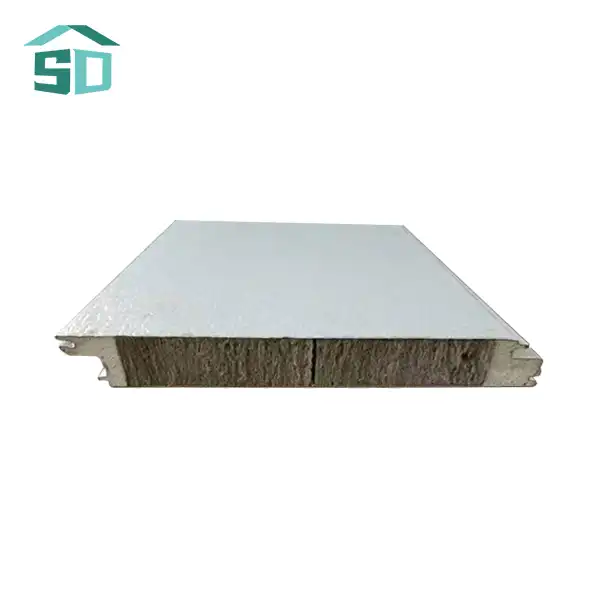

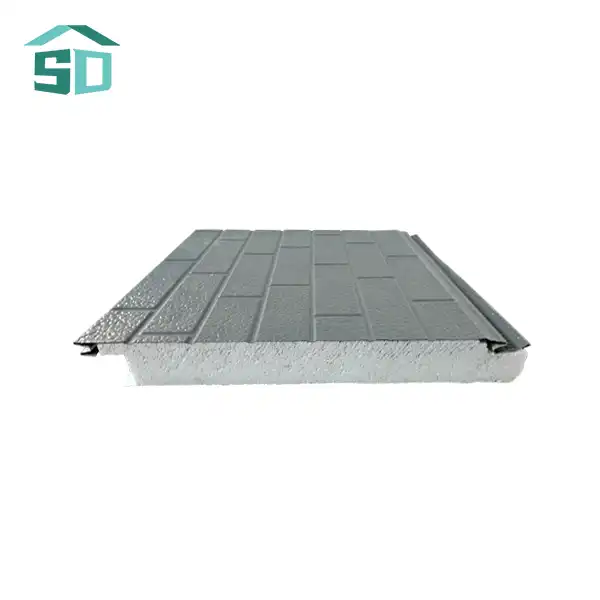

Versatile Applications in Construction

Polyurethane insulation panels find applications in various construction projects due to their excellent thermal properties and versatility. They are suitable for walls, roofs, and ceilings in residential, commercial, and industrial settings. Their lightweight yet durable nature makes them ideal for both new constructions and renovation projects, including historic building restorations. Furthermore, their adaptability allows for creative architectural solutions, supporting design flexibility without compromising energy performance or structural integrity.

Environmental Impact and Sustainability

While providing excellent insulation, polyurethane panels also contribute to sustainability goals. Their long lifespan and energy-saving properties reduce the overall environmental impact of buildings. Additionally, many manufacturers are now focusing on using environmentally friendly materials and processes in the production of these panels, further enhancing their eco-friendly credentials. By reducing energy consumption over decades, these panels support global efforts to lower greenhouse gas emissions and create greener, more sustainable built environments.

Conclusion

The high R-value of polyurethane insulation panels makes them an excellent choice for energy-efficient construction. Their superior thermal performance, coupled with versatility and durability, positions them as a leading solution in modern building insulation. For those seeking to optimize their building's energy efficiency and comfort, polyurethane insulation panels offer a compelling option. If you're interested in learning more about these innovative insulation solutions, don't hesitate to reach out to us at info@sdqsc.com for expert advice and tailored recommendations.