The Unique Properties of Corrugated Steel Siding Panels

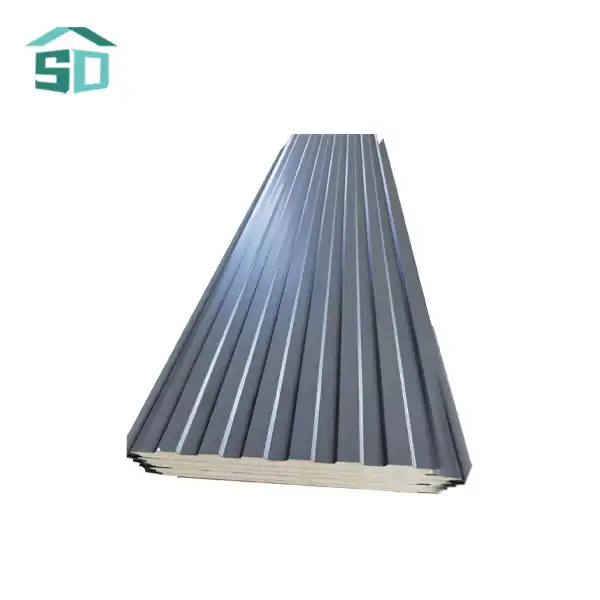

Corrugated steel siding panels have become increasingly popular in modern architecture and construction, thanks to their remarkable blend of strength and style. These panels are engineered to provide unmatched durability and weather resistance, making them an ideal choice for both residential and commercial applications.

Strength and Insulation: The Power of Corrugation

The particular folded design of these boards is not fair for appear. The rotating edges and valleys altogether improve the material's auxiliary astuteness, permitting it to withstand overwhelming loads and stand up to bowing. This special plan too makes discuss pockets that contribute to made strides warm cover, making a difference to keep up comfortable indoor temperatures year-round.

Customizable Aesthetics: A Palette of Possibilities

Gone are the days when corrugated steel was synonymous with industrial monotony. Modern corrugated steel siding panels offer a wide array of color options and optional coatings, allowing architects and homeowners to fully customize the appearance of their structures. From classic metallic finishes to bold, vibrant hues, these panels can seamlessly integrate with any architectural style, from rustic farmhouses to sleek, contemporary designs.

Longevity and Energy Efficiency: A Sustainable Choice

Folded steel siding boards are built to final. Their solidness deciphers into lower support costs and less substitutions over time, making them a cost-effective arrangement in the long run. In addition, their great warm separator properties contribute to vitality productivity, possibly lessening warming and cooling costs. This combination of life span and vitality effectiveness makes layered steel siding boards an eco-friendly alternative for those looking for maintainable building arrangements.

The Technical Specifications of Corrugated Steel Siding Panels

Understanding the technical aspects of corrugated steel siding panels can help builders and homeowners make informed decisions about their construction materials. Let's delve into the specific characteristics that make these panels stand out in the world of exterior cladding.

Material Composition and Dimensions

Layered steel siding boards are regularly created from high-quality galvanized steel, which gives a strong establishment for their execution. These boards are accessible in different thicknesses, commonly advertised in 24, 26, and 28 gage choices. The standard board width is 36 inches, permitting for productive scope of huge zones. One of the most profitable highlights is the capacity to customize lengths up to 30 feet, empowering consistent application over broad surfaces with negligible creases.

Fire Safety and Corrosion Resistance

Safety is paramount in construction, and corrugated steel siding panels excel in this regard. They boast a Class A fire rating, meeting stringent fire safety standards for both residential and commercial use. This non-flammable nature provides an additional layer of protection for buildings and their occupants. Furthermore, these panels are designed to be corrosion-proof, effectively safeguarding against rust and other forms of deterioration. This resistance to corrosion ensures that the panels maintain their structural integrity and appearance for years to come, even in harsh environmental conditions.

Insulation Options and Environmental Impact

For improved warm execution, folded steel siding boards can be combined with cover materials such as polyurethane or polystyrene. This discretionary highlight assist moves forward the vitality proficiency of buildings, contributing to more comfortable living spaces and diminished vitality costs. From a natural point of view, steel is a maintainable choice for development. It's recyclable and requires less vitality to deliver compared to a few elective materials, adjusting with green building activities and decreasing the generally carbon impression of development ventures.

The Versatility and Applications of Corrugated Steel Siding Panels

The adaptability of corrugated steel siding panels makes them a favored choice across a wide spectrum of construction projects. Their unique combination of durability, aesthetics, and functionality opens up a world of possibilities for architects, builders, and property owners alike.

Residential Applications: From Modern Homes to Rustic Retreats

In the residential sector, corrugated steel siding panels have transcended their industrial roots to become a sought-after material for contemporary home design. They're equally at home on sleek, minimalist urban dwellings as they are on rustic country houses. The panels' ability to withstand harsh weather conditions makes them particularly suitable for coastal homes or mountain retreats exposed to extreme elements. Moreover, their low maintenance requirements appeal to homeowners looking for durable, long-lasting exterior solutions.

Commercial and Industrial Uses: Strength Meets Style

The robust nature of corrugated steel siding panels makes them an excellent choice for commercial and industrial buildings. Warehouses, factories, and storage facilities benefit from the panels' strength and weather resistance. However, their use isn't limited to purely functional structures. Modern office buildings, retail spaces, and even schools are incorporating these panels into their designs, leveraging their aesthetic versatility to create visually striking facades that also offer practical benefits.

Renovation and Restoration: Breathing New Life into Old Structures

Corrugated steel siding panels are not just for new construction. They're increasingly being used in renovation and restoration projects, offering a way to update the look and improve the performance of older buildings. Historical structures can be sensitively modernized while maintaining their character, thanks to the panels' ability to mimic traditional materials or provide a contrasting contemporary touch. This versatility in renovation contexts demonstrates the material's ability to bridge the gap between preservation and innovation in architecture.

Conclusion

Corrugated steel siding panels offer a unique combination of strength, style, and sustainability that makes them a versatile choice for a wide range of construction projects. From their superior durability and weather resistance to their customizable aesthetics and energy efficiency, these panels provide solutions that meet the diverse needs of modern architecture and construction. As the building industry continues to evolve, corrugated steel siding panels are poised to play an increasingly important role in shaping the structures of tomorrow. For more information about our exterior cladding and facade solutions, including corrugated steel siding panels, please don't hesitate to contact us at info@sdqsc.com.