Revolutionizing Aesthetics: The Evolution of Wood Grain Patterns

Wood grain metal siding has come a long way in mimicking the authentic look of natural wood. As we move towards 2025, this evolution is set to accelerate, bringing unprecedented realism and variety to exterior cladding options.

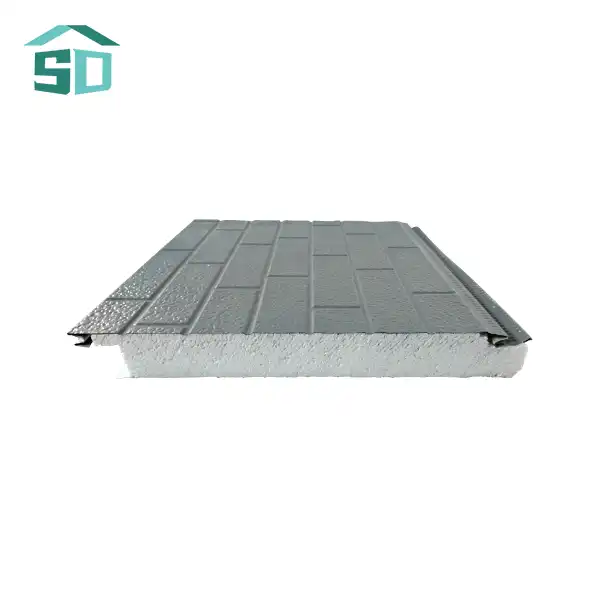

Hyper-Realistic Textures and Patterns

Advancements in manufacturing techniques are enabling the creation of wood grain metal siding with textures so lifelike, they're nearly indistinguishable from genuine wood. These hyper-realistic patterns capture the intricate details of wood grain, including knots, whorls, and even the subtle variations in color that occur naturally in wood.

Manufacturers are utilizing cutting-edge 3D printing technologies to emboss metal surfaces with incredibly detailed wood grain patterns. This process allows for the replication of a wide variety of wood species, from the straight grain of pine to the complex figuring of burl wood. The result is a product that offers the warmth and character of wood with the durability and low maintenance of metal.

Customizable Wood Grain Finishes

Customization is becoming increasingly important in architectural design, and wood grain metal siding is no exception. In 2025, we can expect to see a surge in customizable wood grain finishes that allow architects and homeowners to create truly unique exteriors. Advanced digital printing techniques are making it possible to reproduce any wood grain pattern on metal siding. This means clients can select from an extensive library of wood grain patterns or even submit their own designs.

When it comes to imitating the appearance of reclaimed barn wood or crafting a unique pattern, the potential for creativity is nearly boundless. Whether you aim to replicate the rustic charm of weathered barn planks or design an exclusive, eye-catching motif, the range of possibilities allows for extensive customization and artistic expression. This flexibility enables you to bring forth distinctive designs that suit various styles and preferences, making each project a special reflection of individual taste.

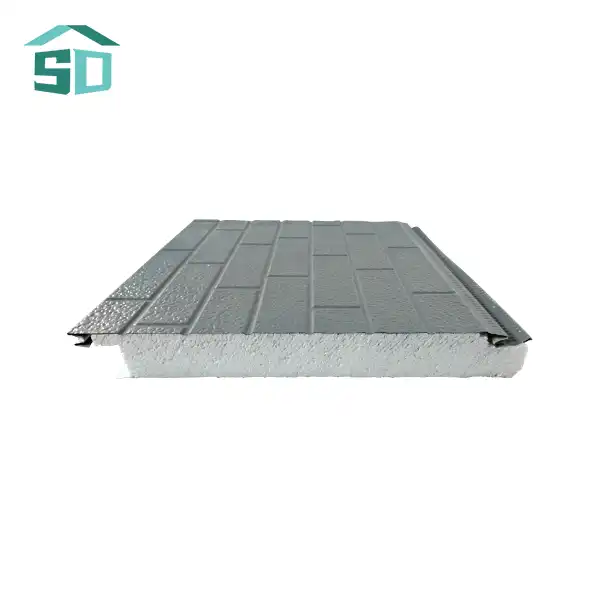

Dynamic Color Options

While traditional wood tones remain popular, 2025 will see an expansion of color options in wood grain metal siding. Manufacturers are developing innovative finishes that allow for a broader range of colors while still maintaining the authentic look of wood grain.

These new color options include everything from subtle, weathered grays to bold, vibrant hues. Some manufacturers are even experimenting with color-changing finishes that react to temperature or light, adding a dynamic element to building exteriors.

Enhancing Performance: Technological Advancements in Wood Grain Metal Siding

As aesthetic preferences continue to evolve, the performance of wood grain metal siding is also undergoing significant improvement. Technological innovations are progressively expanding the capabilities of this material, particularly in areas such as durability, energy efficiency, and overall functionality. With each advancement, wood grain metal siding not only meets the changing demands of design aesthetics but also delivers enhanced practical benefits, making it a more versatile and reliable choice for modern architectural applications. This combination of evolving style and technological progress ensures that the material remains at the forefront of both visual appeal and performance-driven solutions.

Nano-Coating Technology

One of the most significant developments in wood grain metal siding is the application of nano-coating technology. These microscopic coatings are revolutionizing the way metal siding resists weathering and corrosion.

Nano-coatings create an ultra-thin, invisible layer on the surface of the metal siding. This layer repels water, dirt, and even harmful UV rays, significantly extending the life of the siding and reducing maintenance needs. Some nano-coatings also have self-cleaning properties, using sunlight to break down organic matter and keep the siding looking fresh.

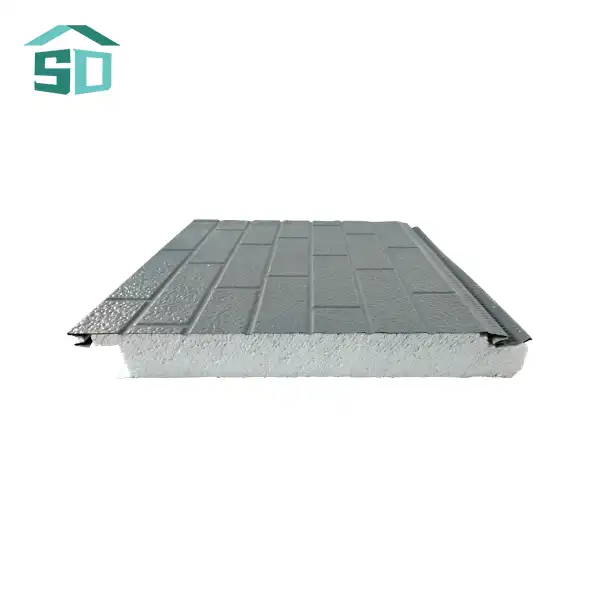

Advanced Insulation Systems

Energy efficiency is a top priority in modern construction, and wood grain metal siding is adapting to meet these demands. Manufacturers are developing innovative insulation systems that integrate seamlessly with metal siding panels.

These advanced insulation systems often utilize materials like polyurethane or polystyrene, which offer superior thermal performance. Some systems even incorporate phase-change materials that absorb and release heat as needed, helping to maintain consistent indoor temperatures and reduce energy costs.

Smart Siding Integration

As smart home technology continues to evolve, wood grain metal siding is becoming part of the connected home ecosystem. Smart siding systems are being developed that can monitor various aspects of a building's exterior performance.

These systems may include sensors that detect moisture intrusion, thermal imaging capabilities to identify insulation gaps, or even self-reporting features that alert homeowners to potential maintenance issues. By integrating with home automation systems, smart siding can provide real-time data on a building's exterior health and energy performance.

Sustainability and Environmental Considerations

As environmental concerns continue to shape the construction industry, wood grain metal siding is positioning itself as a sustainable alternative to traditional materials. The trends for 2025 show a strong focus on eco-friendly practices and materials.

Recycled and Recyclable Materials

Manufacturers are increasingly using recycled materials in the production of wood grain metal siding. Aluminum and steel, the main materials used in metal siding, are highly recyclable and can be reused many times without quality loss.

Some companies are going a step further by developing closed - loop recycling programs. These efforts enable the collection and recycling of old metal siding, which can then be utilized to make new products. This method greatly lessens the environmental effect of production and aids in preserving natural resources.

Energy-Efficient Manufacturing

The production of wood grain metal siding is becoming more energy-efficient. Manufacturers are putting money into cleaner technologies and processes to cut their carbon footprint. This includes the use of renewable energy sources in production facilities and the implementation of energy recovery systems that capture and reuse waste heat.

Additionally, advancements in coating technologies are allowing for lower-temperature curing processes, which further reduce energy consumption during manufacturing. These energy-efficient practices not only benefit the environment but also help to keep production costs down, making wood grain metal siding a more affordable option for consumers.

Life Cycle Assessment

As sustainability becomes increasingly important to consumers and regulators alike, manufacturers are conducting comprehensive life cycle assessments of their wood grain metal siding products. These assessments consider the environmental impact of the product from raw material extraction through manufacturing, use, and eventual disposal or recycling.

This comprehensive approach to sustainability assists manufacturers in pinpointing areas needing improvement and creating more eco - friendly products. It also offers useful information to architects and homeowners aiming to make well - informed choices about the materials used in their projects.

Conclusion

Wood grain metal siding is rapidly evolving to meet the demands of modern construction while maintaining its aesthetic appeal. As we look towards 2025, it's clear that this versatile material will continue to play a significant role in shaping the future of building exteriors. From hyper-realistic wood grain patterns to advanced performance features and sustainable manufacturing practices, wood grain metal siding is at the forefront of innovation in exterior cladding solutions.

For those interested in learning more about the latest developments in wood grain metal siding and other exterior cladding solutions, Weifang Sandong Building Materials Co., Ltd. is at the forefront of these innovations. Our team of experts is always available to discuss how these trends can be applied to your specific project needs. Don't hesitate to reach out to us at info@sdqsc.com for more information or to explore our range of cutting-edge products.