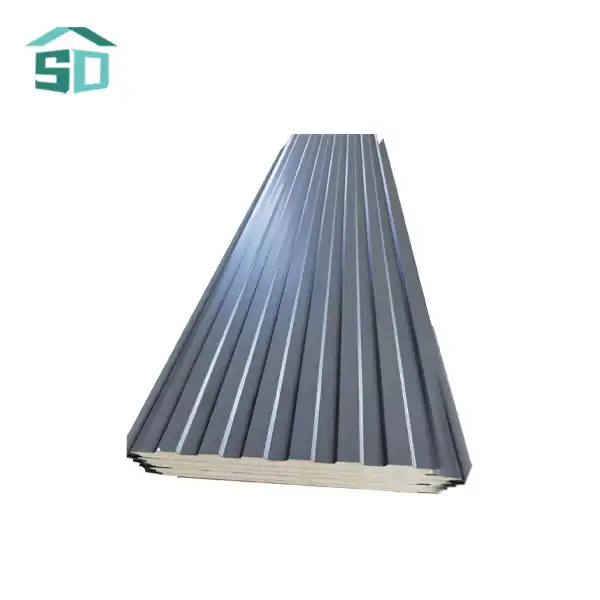

The Composition of Metal Insulated Sandwich Panels: A Closer Look

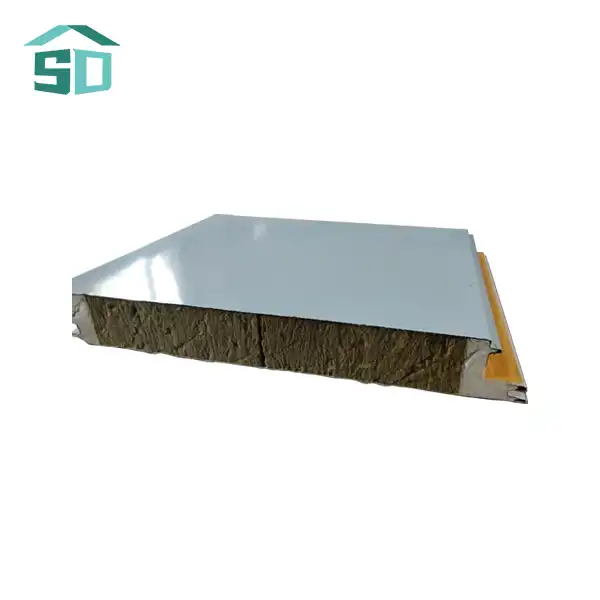

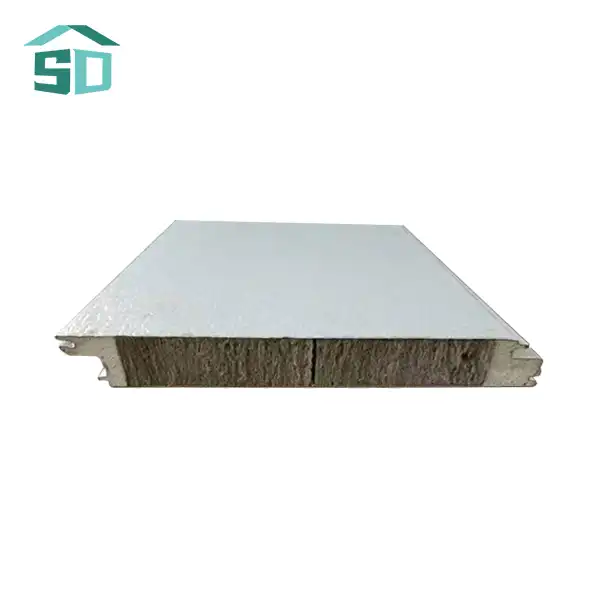

Exterior and Interior Metal Skins

The outer layers of metal insulated sandwich panels play a crucial role in their overall performance and durability. These skins are typically fabricated from high-quality steel or aluminum, chosen for their strength, corrosion resistance, and aesthetic appeal. The thickness of these metal skins can vary, with common options ranging from 0.23mm to 0.27mm, depending on the specific requirements of the project.

Steel is often preferred for its superior strength and cost-effectiveness, while aluminum is valued for its lightweight nature and resistance to corrosion. Both materials can be treated with protective coatings to enhance their weather resistance and longevity. These coatings may include galvanization for steel or anodization for aluminum, providing an additional layer of protection against environmental factors.

Insulating Core: The Heart of the Panel

The insulating core is the key component that gives metal insulated sandwich panels their exceptional thermal performance. The most commonly used materials for the core are polyurethane (PU) and polyisocyanurate (PIR) foams. These advanced insulation materials offer several advantages:

- Excellent thermal conductivity (as low as 0.018 W/m.k)

- High thermal resistance (up to 2.09 m2k/w)

- Impressive compressive strength (52.7 kPa)

- Exceptional fire resistance (B1/B2 fire protection rating)

The thickness of the insulating core can be customized to meet specific project requirements. For interior applications, a thickness of 10mm is often sufficient, while exterior panels may require thicknesses of 16mm or 20mm to provide optimal insulation performance.

Adhesives and Bonding Agents

To ensure the structural integrity of metal insulated sandwich panels, high-performance adhesives and bonding agents are used to join the metal skins to the insulating core. These adhesives are carefully selected to withstand various environmental conditions, including temperature fluctuations, moisture, and UV exposure. The bonding process is critical in creating a unified panel that can withstand wind loads of up to 8.0 kPa and maintain a waterproof rate of 0.0008.

Enhancing Performance: Additional Materials and Treatments

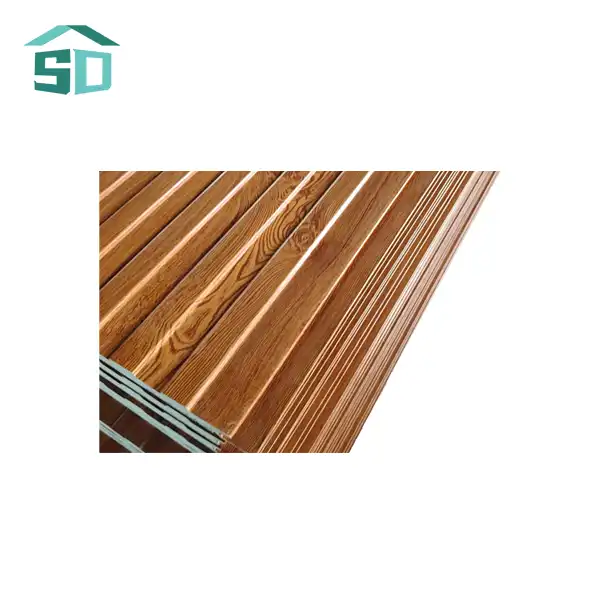

Protective Coatings and Finishes

To further improve the durability and aesthetics of metal insulated sandwich panels, various protective coatings and finishes can be applied to the exterior metal skin. These may include:

- Polyester powder coatings for enhanced color retention and weather resistance

- PVDF (polyvinylidene fluoride) coatings for superior UV protection and chemical resistance

- Textured finishes to mimic the appearance of wood, stone, or other materials

These coatings not only protect the panels from environmental factors but also allow for a wide range of customization options to suit different architectural styles and design preferences.

Vapor Barriers and Moisture Management

To anticipate dampness invasion and guarantee long-term execution, metal protects sandwich boards frequently consolidate vapor obstructions or dampness administration frameworks. These extra layers offer assistance keep up the keenness of the protection center and anticipate condensation issues inside the board structure. Materials such as polyethylene movies or specialized moisture-resistant films may be coordinates into the board plan to accomplish ideal dampness control.

Fire-Retardant Additives

Whereas the center materials of metal protects sandwich boards as of now offer great fire resistance, extra fire-retardant added substances can be consolidated to encourage upgrade their security execution. These added substances work by restraining fire spread and decreasing smoke era in the occasion of a fire. The integration of these materials makes a difference metal protects sandwich boards accomplish higher fire assurance evaluations, making them reasonable for utilize in different building sorts and inhabitances.

Sustainable and Eco-Friendly Material Options

Recycled and Recyclable Materials

As the construction industry increasingly focuses on sustainability, manufacturers of metal insulated sandwich panels are exploring ways to incorporate recycled and recyclable materials into their products. This may include:

- Using recycled steel or aluminum for the metal skins

- Incorporating recycled content into the insulating core

- Designing panels for easy disassembly and recycling at the end of their life cycle

By utilizing these sustainable materials, metal insulated sandwich panels can contribute to green building certifications and reduce the overall environmental impact of construction projects.

Bio-Based Insulation Materials

Research and development efforts are also focused on creating bio-based alternatives to traditional petrochemical-derived insulation materials. These innovative solutions may include:

- Soy-based polyurethane foams

- Cellulose-derived insulation materials

- Natural fiber-reinforced composites

While these bio-based options are still in various stages of development and commercialization, they represent a promising direction for the future of sustainable building materials.

Low-VOC and Environmentally Friendly Adhesives

To encourage upgrade the natural profile of metal protects sandwich boards, producers are investigating the utilize of low-VOC (unstable natural compound) and ecologically neighborly cements. These progressed holding operators offer comparable execution to conventional cements whereas minimizing the discharge of hurtful chemicals into the environment amid generation and all through the life of the board.

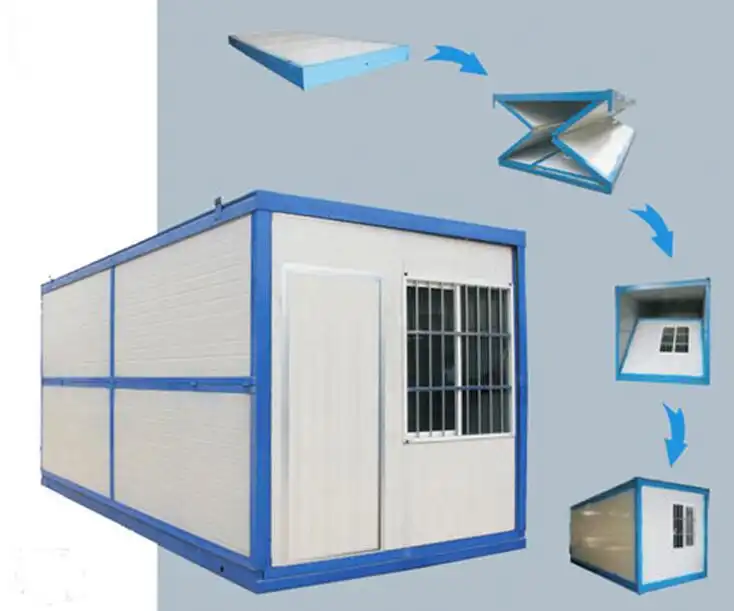

Conclusion

Metal insulated sandwich panels represent a sophisticated blend of materials engineered to deliver outstanding performance in modern construction projects. From the durable metal skins to the high-performance insulating core, each component is carefully selected and optimized to create a versatile, energy-efficient, and aesthetically pleasing building solution. As technology advances and sustainability becomes increasingly important, we can expect to see continued innovation in the materials used in these panels, further enhancing their value in the construction industry.

For more information about our metal insulated sandwich panels and other exterior cladding and facade solutions, please don't hesitate to contact us at info@sdqsc.com. Our team at Weifang Sandong Building Materials Co., Ltd. is committed to providing you with the highest quality products and unparalleled service to enhance your construction projects.