The Eco-Friendly Attributes of Polyurethane Sandwich PUF Panels

Energy Efficiency and Thermal Performance

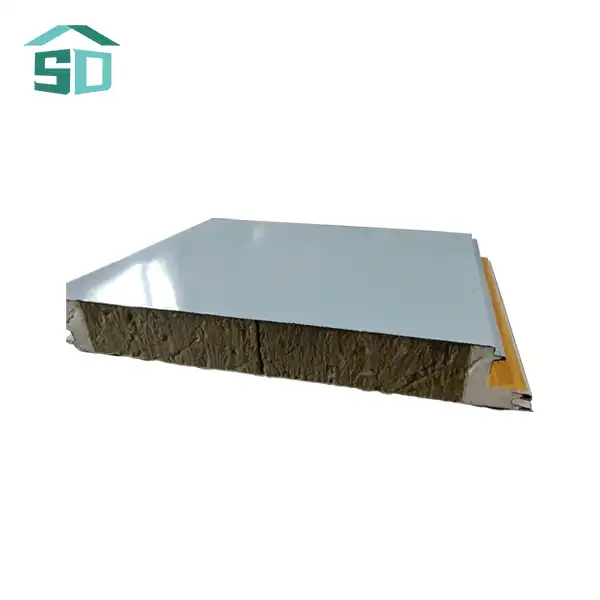

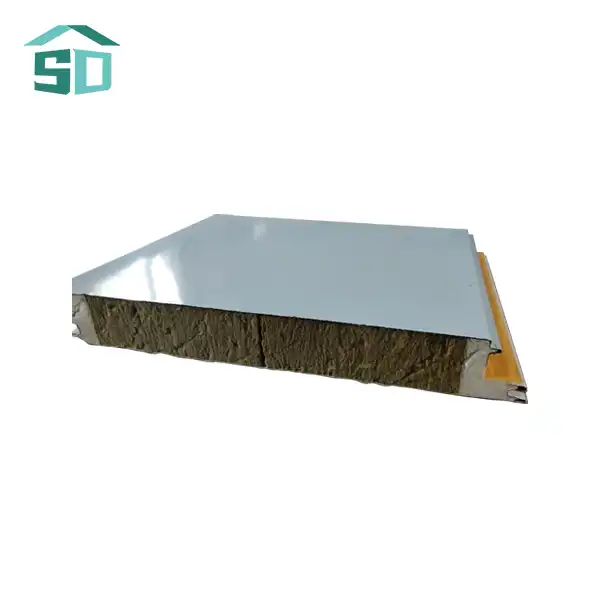

One of the most significant environmental benefits of polyurethane sandwich PUF panels lies in their outstanding thermal sequestration parcels. With a remarkably low thermal conductivity of 0.018 W/m.k, these panels are complete at maintaining ideal temperatures year-round, significantly reducing the energy needed for heating and cooling. This exceptional thermal performance translates to lower energy consumption in structures, which in turn leads to reduced greenhouse gas emissions.

The thermal resistance of 2.09m2k/w further underscores the panels' ability to resist heat flow, ensuring that indoor spaces remain comfortable with minimal reliance on HVAC systems. By creating a more stable indoor environment, polyurethane sandwich PUF panels contribute to the overall energy efficiency of structures, aligning with global efforts to combat climate change.

Durability and Longevity

The environmental impact of building materials extends beyond their initial production to their lifespan and maintenance requirements. Polyurethane sandwich PUF panels excel in this aspect, boasting remarkable durability that translates to a longer service life. These panels are engineered to withstand harsh weather conditions, including high winds up to 8.0 Kpa, and feature a waterproof rate of 0.0008, ensuring they remain effective and intact for extended periods.

The longevity of PUF panels means fewer replacements over time, reducing the demand for new materials and the associated environmental costs of production and disposal. This durability is complemented by the panels' resistance to corrosion and their ability to maintain their structural integrity, further extending their useful life and minimizing waste.

Sustainable Manufacturing and Material Composition

The production of polyurethane sandwich PUF panels incorporates sustainable practices and materials, contributing to their overall environmental friendliness. Manufacturers are increasingly adopting eco-conscious approaches, utilizing recycled content where possible and optimizing production processes to reduce waste and energy consumption.

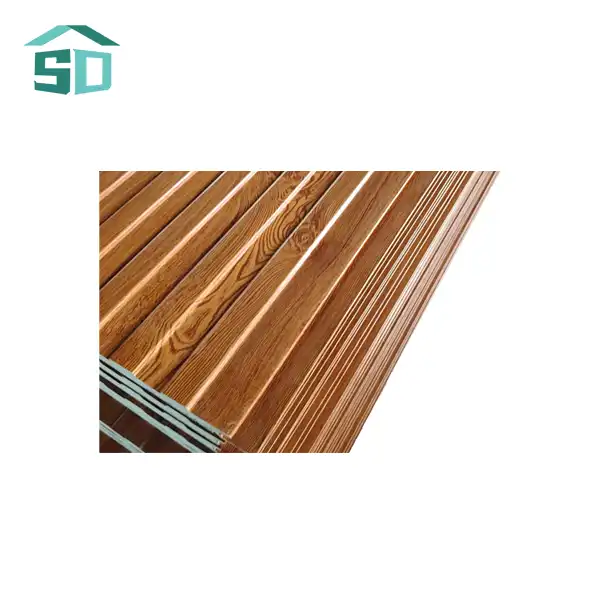

The lightweight nature of these panels, with customizable thicknesses ranging from 10mm for interior applications to 16mm or 20mm for exterior use, not only facilitates easier handling and installation but also reduces transportation-related emissions. The ability to customize panel sizes and finishes further minimizes waste during the construction process, as materials can be tailored to exact project specifications.

Environmental Impact Throughout the Lifecycle

Energy Savings in Buildings

The environmental benefits of polyurethane sandwich PUF panels extend well beyond their production and installation phases. Throughout their lifecycle, these panels play a crucial role in reducing the energy consumption of buildings. The superior insulation provided by PUF panels helps maintain consistent indoor temperatures, reducing the load on heating and cooling systems.

This energy efficiency translates to significant reductions in a building's carbon footprint over time. In residential complexes, offices, and other structures where PUF panels are utilized, the cumulative energy savings can be substantial, contributing to broader sustainability goals and reducing operational costs for building owners and occupants.

Recyclability and End-of-Life Considerations

As the construction industry moves towards more circular economic models, the recyclability of building materials becomes increasingly important. Polyurethane sandwich PUF panels offer promising opportunities for recycling and repurposing at the end of their useful life. While the recycling processes for these composite materials are still evolving, advancements in technology are making it increasingly feasible to separate and recycle the components of PUF panels.

The potential for recycling not only reduces the amount of waste sent to landfills but also decreases the demand for virgin materials in future production cycles. This aspect of PUF panels aligns with sustainable waste management practices and supports the transition towards a more circular economy in the construction sector.

Contribution to Green Building Certifications

The use of polyurethane sandwich PUF panels can contribute significantly to achieving green building certifications such as LEED (Leadership in Energy and Environmental Design). These panels' energy efficiency, durability, and potential for recycling align with many of the criteria assessed in green building standards.

By incorporating PUF panels into their designs, architects and builders can earn points towards certification, demonstrating their commitment to sustainable construction practices. This not only enhances the environmental credentials of a project but can also lead to long-term benefits in terms of building performance and marketability.

Balancing Environmental Considerations with Performance

Fire Safety and Environmental Protection

One of the challenges in developing environmentally friendly building materials is ensuring that they meet rigorous safety standards without compromising their eco-credentials. Polyurethane sandwich PUF panels address this concern by incorporating flame-retardant properties that meet B1/B2 fire safety standards. This enhanced fire resistance is achieved while maintaining the panels' overall environmental benefits, striking a crucial balance between safety and sustainability.

The ability to provide robust fire protection without relying on harmful chemicals or compromising the material's recyclability showcases the innovative approach taken in the development of these panels. This aspect of PUF panels is particularly important in the context of increasing focus on building safety and environmental health.

Customization and Resource Efficiency

The customizable nature of polyurethane sandwich PUF panels contributes to their environmental friendliness by promoting resource efficiency. With the ability to tailor panel sizes, thicknesses, and finishes to meet specific project requirements, waste is minimized during both production and installation phases. This level of customization ensures that materials are used optimally, reducing excess and improving overall sustainability.

For example, the availability of different surface material thicknesses (0.23mm, 0.25mm, 0.27mm) and widths (383mm exterior, 450mm interior) allows for precise matching to project specifications. This flexibility not only enhances the aesthetic appeal of buildings but also ensures that resources are utilized efficiently, further reinforcing the environmental benefits of choosing PUF panels.

Long-term Environmental Impact Assessment

When evaluating the environmental friendliness of polyurethane sandwich PUF panels, it's essential to consider their long-term impact. The durability and performance characteristics of these panels, including their compressive strength of 52.7kpa and wind resistance up to 8.0 Kpa, ensure that they maintain their effectiveness over extended periods. This longevity reduces the need for frequent replacements, thereby minimizing the environmental impact associated with manufacturing and installing new materials.

Furthermore, the energy savings accrued over the lifetime of a building equipped with PUF panels can offset the initial environmental costs of production. As buildings account for a significant portion of global energy consumption, the cumulative effect of using high-performance insulation materials like PUF panels can contribute substantially to reducing overall environmental impact in the construction sector.

Conclusion

Polyurethane sandwich PUF panels represent a significant stride towards more environmentally friendly building practices. Their combination of energy efficiency, durability, and potential for recycling makes them a compelling choice for sustainable construction projects. While continuous improvement in manufacturing processes and end-of-life management is ongoing, the current environmental benefits of PUF panels are substantial.

As the construction industry continues to evolve towards more sustainable practices, materials like polyurethane sandwich PUF panels will play an increasingly important role in creating energy-efficient, durable, and environmentally responsible buildings. For those seeking to balance performance with environmental considerations in their construction projects, PUF panels offer a solution that meets both criteria admirably.

To learn more about how polyurethane sandwich PUF panels can contribute to your sustainable building goals, or to explore our range of exterior cladding and facade solutions, please contact us at info@sdqsc.com. Our team at Weifang Sandong Building Materials Co., Ltd. is committed to providing innovative, eco-friendly solutions that meet the evolving needs of the construction industry.